An automatic sprinkler irrigation system for agricultural greenhouses

An automatic sprinkler irrigation system and greenhouse technology, applied in agriculture, application, horticulture, etc., can solve the problems of high labor occupation and low degree of automation, and achieve the effect of less labor occupation, high degree of automation, and convenient dismantling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

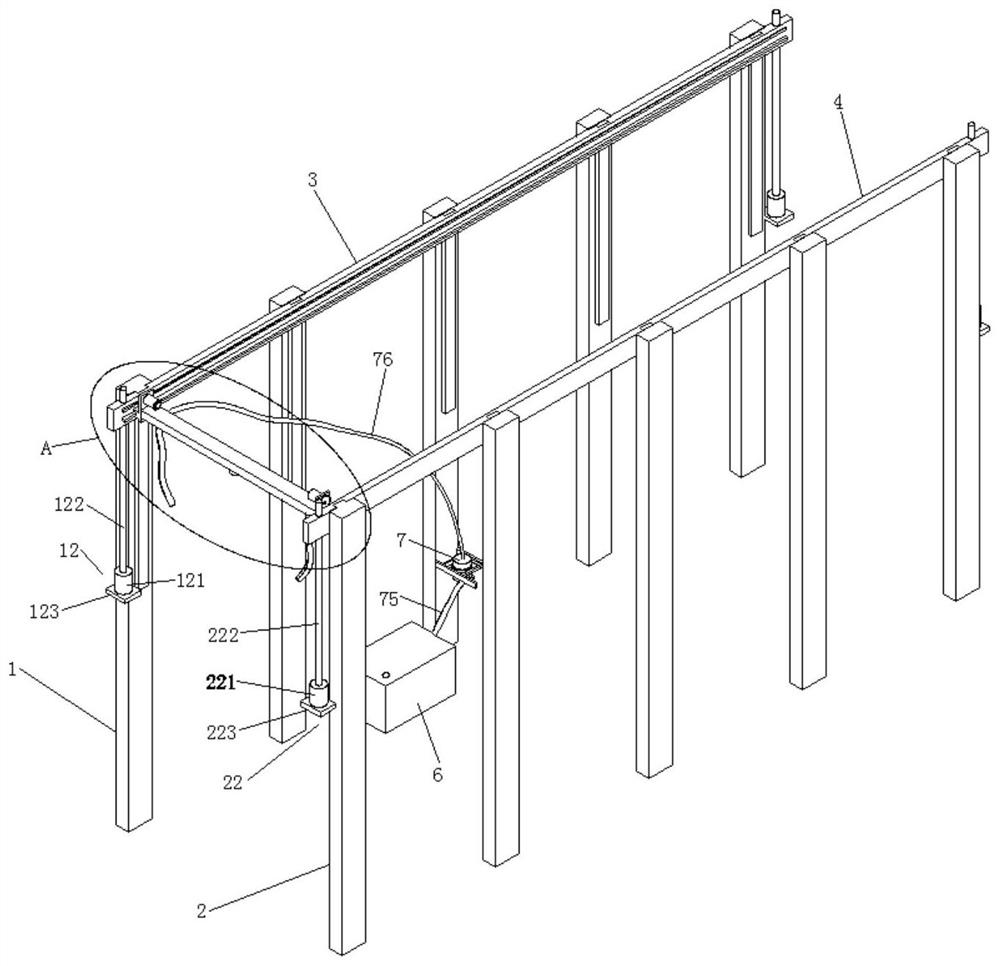

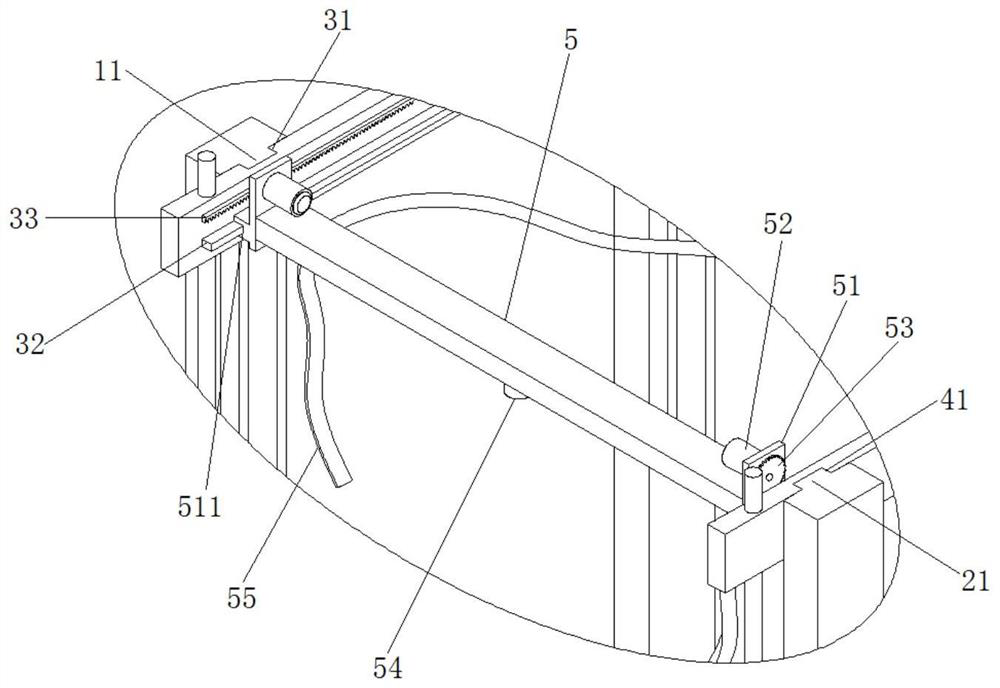

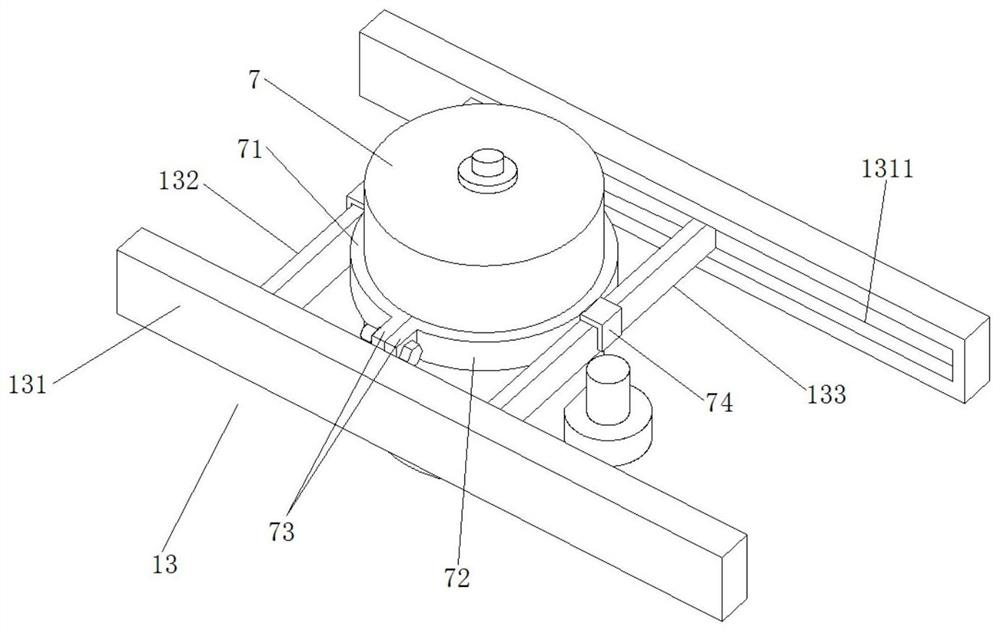

[0030] Such as Figure 1-Figure 3 As shown, the automatic sprinkler irrigation system for agricultural greenhouses of the present invention includes a first column 1, a second column 2, a first transverse guide rail 3, a second transverse guide rail 4, a movable plate 5, a spray water tank 6 and a water pump 7, wherein:

[0031] Both the first column 1 and the second column 2 are vertically arranged, and the lower ends of the first column 1 and the second column 2 are all buried and fixed on the ground, the first column 1 is provided with several pieces and is located on the same straight line, and the second column 2 is provided with Several roots are located on the same straight line.

[0032] The first transverse guide rail 3 can be slid up and down on the upper end of the first column 1, the inner surface of the first column 1 is provided with a first slide rail 11, and the outer surface of the first transverse guide rail 3 is provided with a The first chute 31 of the fir...

Embodiment 2

[0042] An automatic sprinkler irrigation system for agricultural greenhouses, the rest of the technical features are the same as in Embodiment 1, the difference is, refer to Figure 4 , also includes a controller 8 and a timer 9, the timer 9 and the water pump 7 are electrically connected to the controller 8, when in use, the water pump 7 works, the timer 9 can adjust its timing time through the controller 8, when The timer 9 counts to the set time, and the timer 9 transmits the signal to the controller 8, and the controller 8 controls the water pump 7 to stop working, thereby realizing automatic control of the sprinkler irrigation time.

[0043] The front and rear drive motors 53 are variable frequency motors, which can adjust the speed of the front and rear drive motors through frequency conversion, thereby adjusting the front and rear motion speeds of sprinkler irrigation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com