Elevated steel spring floating plate experimental simulation platform

An experimental simulation, steel spring technology, applied in the field of rail transit, can solve problems such as difficult to find user research requirements, unrealistic, huge manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

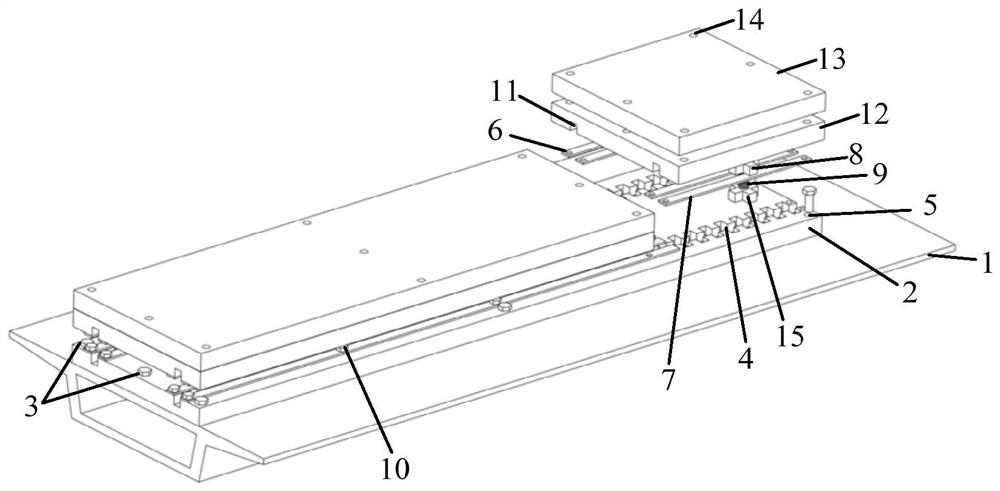

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0027] figure 1 and figure 2 A preferred embodiment of an elevated steel spring floating slab experimental simulation platform according to the present invention is shown. As shown in the figure, the elevated steel spring floating plate experimental simulation platform includes a beam 1, a bottom plate 2, a steel spring assembly and a top plate assembly. Wherein, the beam 1 is located below the bottom plate 2 and connected with the bottom plate 2 . The main function of the bottom plate 2 is to quickly connect the beam 1 and the steel spring assembly and fix the steel spring assembly, so as to realize the rapid change of spring stiffness, spacing and other parameters. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com