Super-long tunnel clean water and sewage separation draining structure suitable for cold regions

A drainage structure and technology in cold regions, applied in drainage, safety devices, mining devices, etc., can solve the problems of difficult construction of deep-buried central ditch, limited drainage capacity, inconvenient maintenance and other problems, and meet high environmental requirements and enhance Drainage capacity, the effect of realizing super large water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

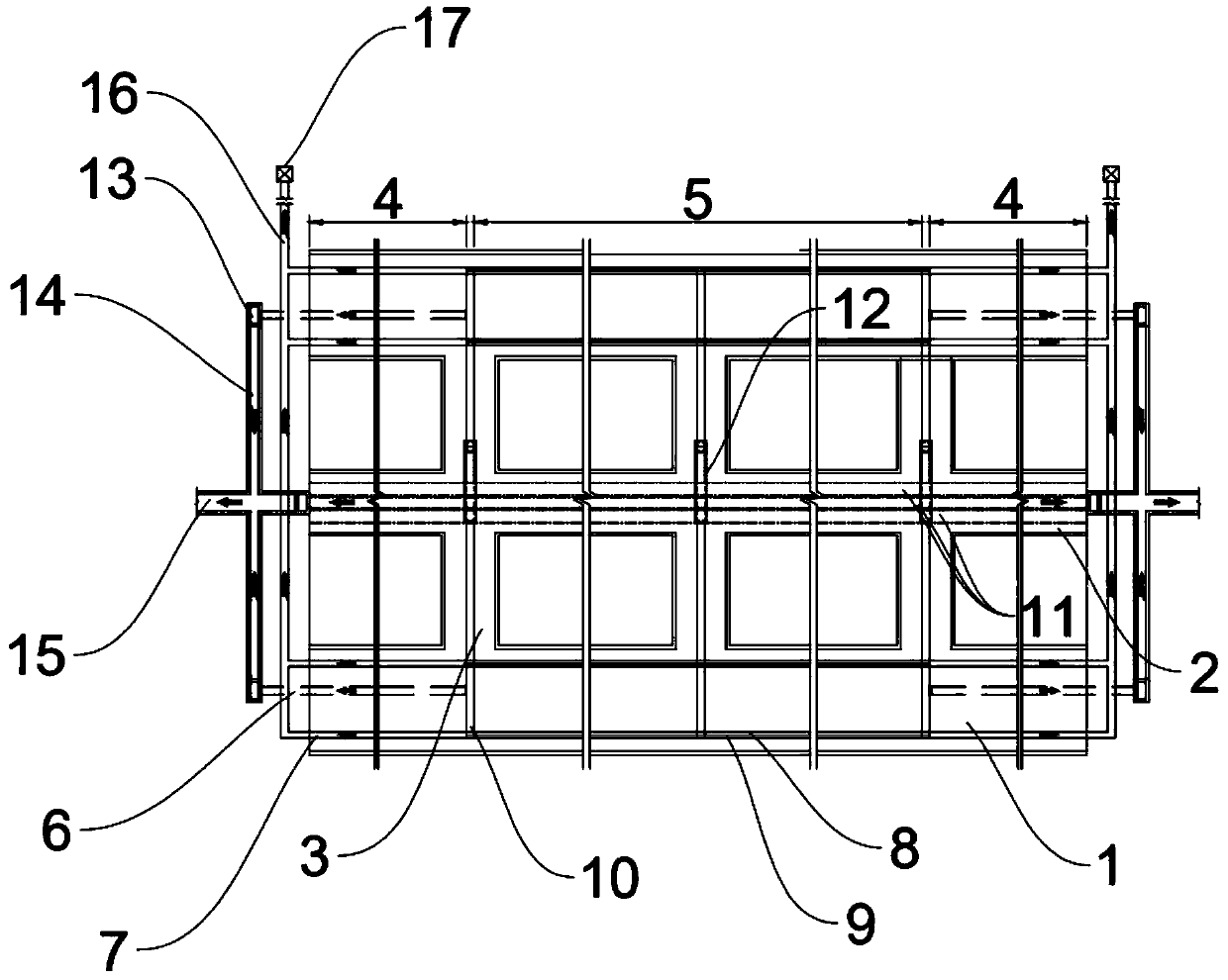

[0028] A highway tunnel to be designed and constructed is 22km long. It is an ultra-long tunnel with a maximum buried depth of about 1150m. It is designed according to the technical standard of 100km / h two-way four-lane highway. High, with large terrain undulations, crossing many landform units, mainly including alpine glacier landform area, alluvial and diluvial erosion valley landform area, foothill slope accumulation landform area, and alpine landform area in tectonic denudation. The altitude is between 2620m-4234m, which is relatively high The difference is 1600m, and there is basically no vegetation above 3500m above sea level, and some parts are covered with snow all the year round. The groundwater types are mainly loose rock pore water, bedrock weathered fissure water, and structural fissure water. The hydrogeological conditions are relatively complex. Considering factors such as disaster prevention and rescue during the operation period of the tunnel, terrain and geolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com