A segmented hank device and production method of long-segment dyed yarn

A hank and long section technology is applied in the production field of segmented hank device and long section dyeing yarn, which can solve the problems of limited length and difficulty in making major breakthroughs in yarn color change, and achieve the effect of changing colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

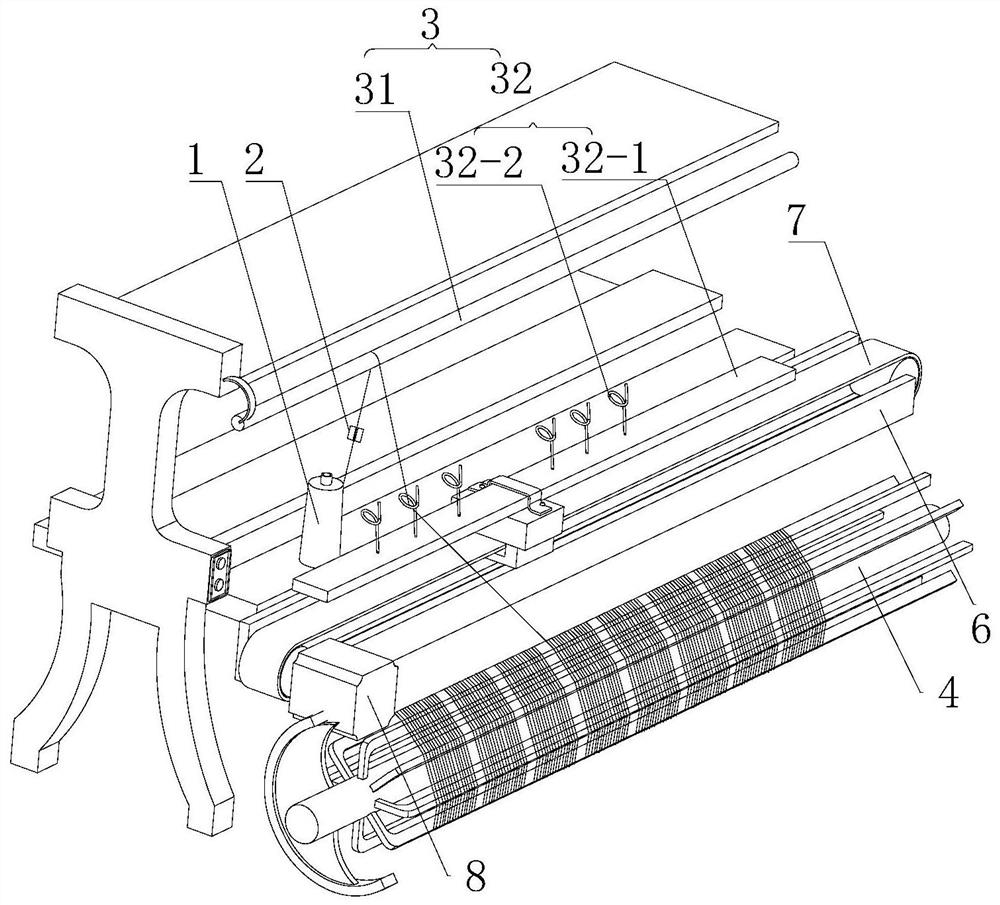

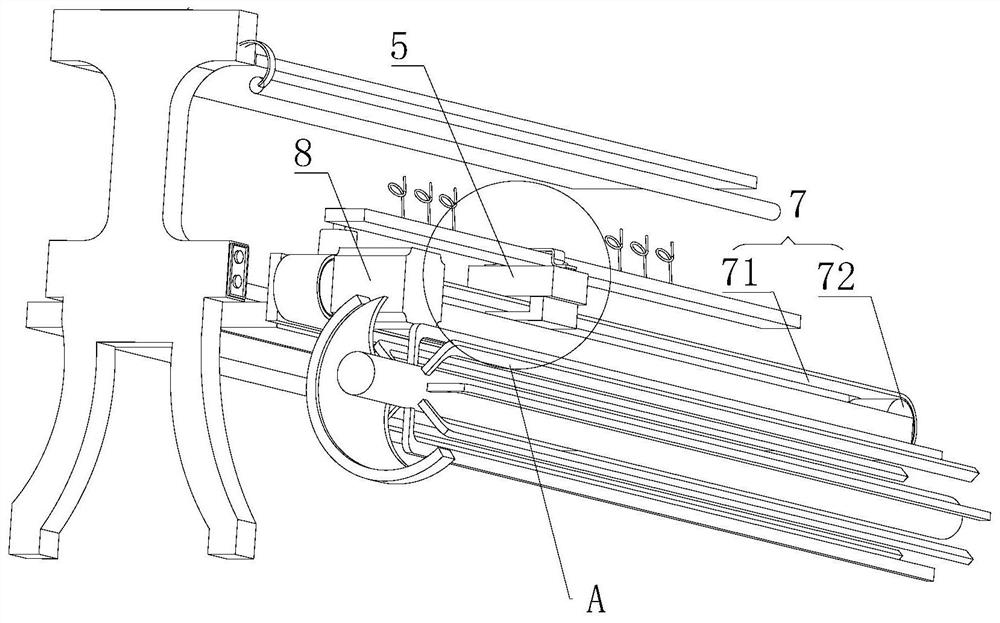

[0027] Example 1: Segmented hank device

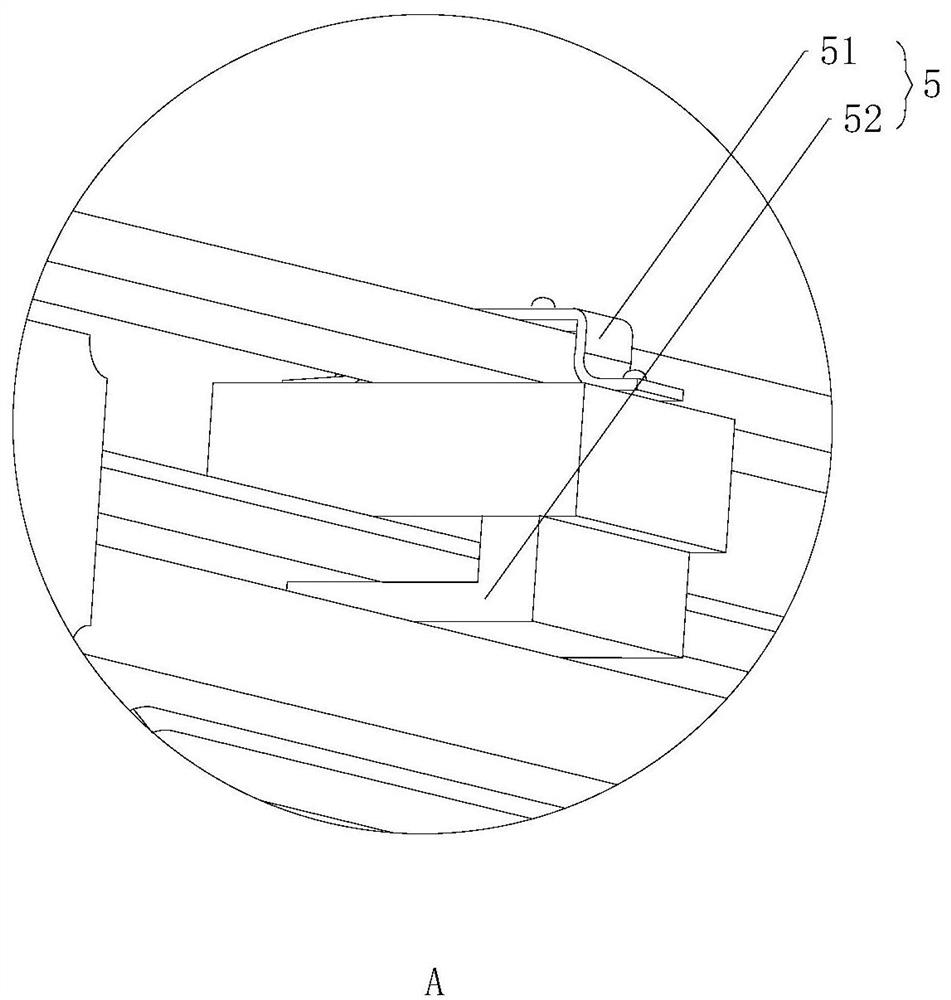

[0028] like Figure 1-3 As shown, a segmented hank device includes a bobbin creel 1, a balloon controller 2, a yarn guide yarn clearing device 3 and a shaking hank device 4, and the yarn guide yarn clearing device 3 includes a relative position of which remains fixed. The guide yarn clearing rod 31 and the reciprocating device 32 whose vertical height is lower than the guide yarn clearing rod 31, take the yarn guide yarn clearing rod 31 and the reciprocating device 32 as the fulcrum, and the yarn passes through the guide yarn clearing rod 31 in a folded line in turn. and reciprocating device 32 . The device replaces the yarn guide rod with the yarn guide hook with a reciprocating device with the yarn guide hook on the basis of the existing shaking machine.

[0029] The reciprocating device 32 includes a plate body 32-1 and a yarn guide hook 32-2. A bracket 6 is provided between the shaking device 4 and the yarn guide and yarn clearin...

Embodiment 2

[0040] Example 2: Application of segment hank device to produce long segment segment dyed yarn

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com