Fermentation tank for preparing biogas by utilizing anaerobic fermentation of livestock and poultry manure and treatment process thereof

An anaerobic fermentation and fermentation tank technology, applied in biological sludge treatment, waste fuel, etc., can solve the problems of unreachable fermentation bacteria, reduced biogas production, incomplete stirring, etc., to increase the fermentation rate and effect, and achieve uniform fermentation temperature. , the effect of increasing the fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

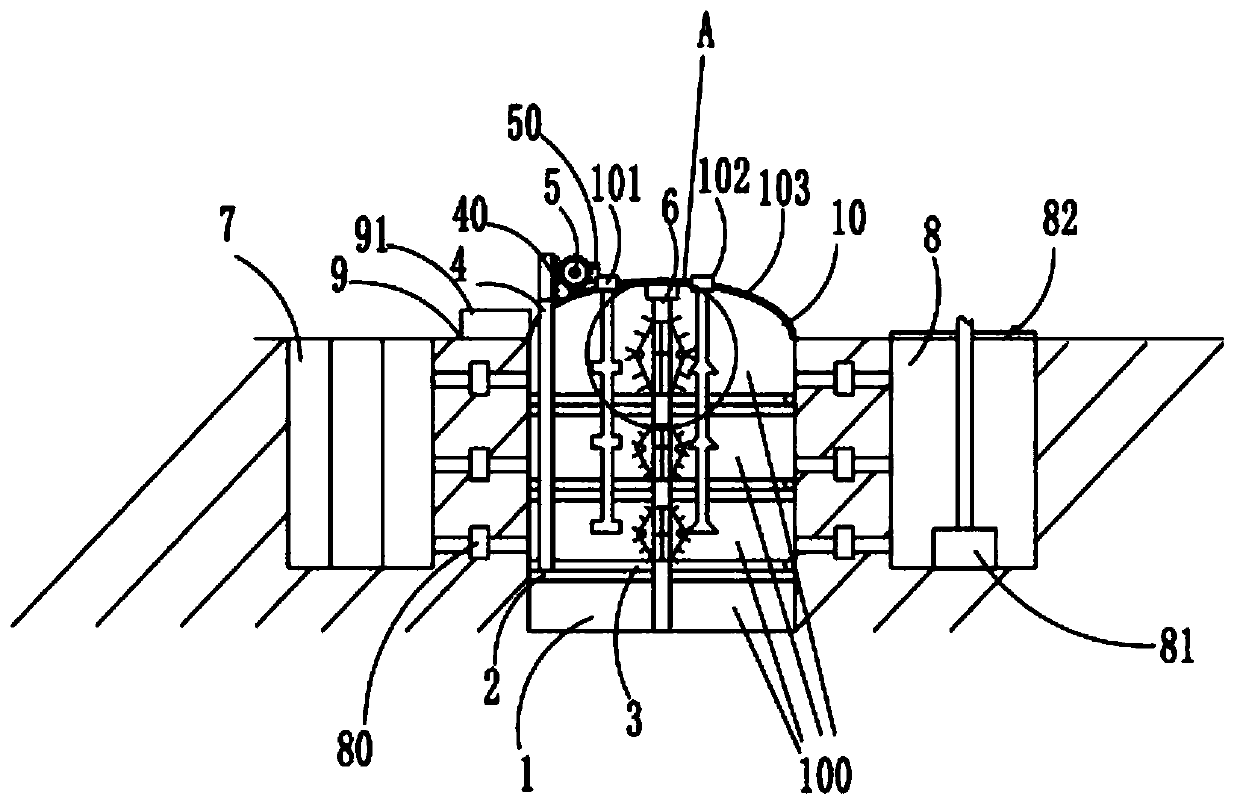

[0035] Example: such as figure 1 , 2 The shown a kind of fermenter that utilizes anaerobic fermentation of livestock and poultry manure to produce biogas mainly includes a fermenter body 1 with a closed canopy 10 at the upper end, which is evenly distributed from top to bottom and horizontally arranged in the fermenter body 1 and Divide the fermentation tank body 1 into four fermentation chambers 100, three partition support plates 2, movable placement boards 3 placed on the upper ends of each partition support board 2, vertically arranged in the fermentation tank body 1 and running through each movable placement board 3 Separate the supporting plate 2 and the lifting rod 4 fixedly connected with the movable placing plate 3, the sliding gear 5 that drives the lifting rod 4 to lift up and down, the excrement stirring element 6 that stirs and ferments the feces that enter the fermentation tank body 1, and passes through the The three connecting pipes at the upper end of each mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com