A kind of modified wood and preparation method and application of modified wood

A wood modification technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of volatile loss of organic components, adverse effects of wood durability, etc., and achieve high promotion and application value, dimensional stability, and cementing performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

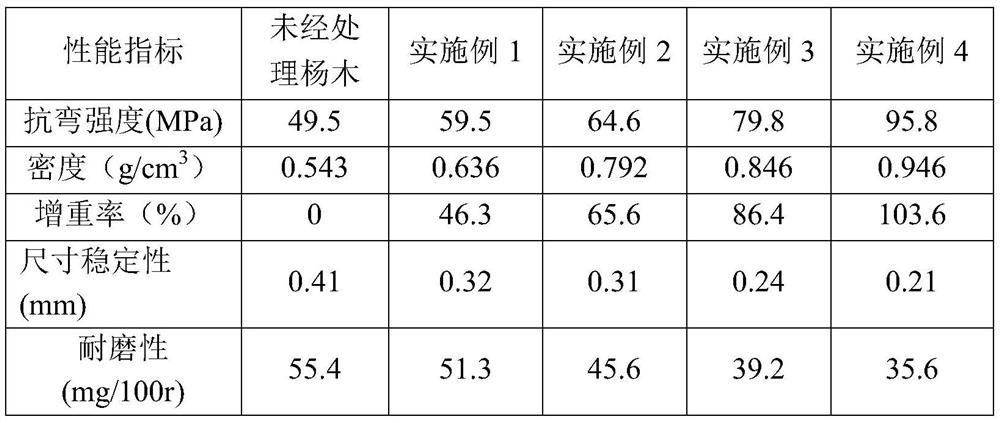

Embodiment 1

[0045] (1) Wood pretreatment: Before impregnation, put the low-density poplar with a size of 20cm×10cm×3cm into an oven at 65° C. to dry until the moisture content is less than 10%.

[0046] (2) Take out the dried poplar wood in step (1), put it in the dipping tank, adjust the pressure inside the tank to a negative pressure of -0.09MPa, and keep it for 2 hours. Then inject silica sol with a solid content of 10% into the tank and fill the tank, then adjust the pressure inside the tank to 1.0 MPa, and keep it for 6 hours, so that the silica sol solution can fully enter the interior of the wood. Release the pressure and drain the excess silica sol solution in the tank.

[0047] (3) Take out the poplar wood impregnated with the silica sol solution in step (2), and put it into an oven with a temperature of 65° C. to dry until the moisture content is less than 10%.

[0048] (4) Take out the dried poplar wood in step (3), put it in the dipping tank, adjust the pressure in the tank to ...

Embodiment 2

[0051] (1) Wood pretreatment: Before impregnation, put the low-density poplar with a size of 20cm×10cm×3cm into an oven at 65° C. to dry until the moisture content is less than 10%.

[0052] (2) Take out the dried poplar wood in step (1), put it in the dipping tank, adjust the pressure inside the tank to a negative pressure of -0.09MPa, and keep it for 2 hours. Then inject silica sol with a solid content of 15% into the tank and fill the tank, then adjust the pressure inside the tank to 1.0 MPa, and keep it for 6 hours, so that the silica sol solution can fully enter the interior of the wood. Release the pressure and drain the excess silica sol solution in the tank.

[0053] (3) Take out the poplar wood impregnated with the silica sol solution in step (2), and put it into an oven with a temperature of 65° C. to dry until the moisture content is less than 10%.

[0054] (4) Take out the dried poplar wood in step (3), put it in the dipping tank, adjust the pressure in the tank t...

Embodiment 3

[0057] (1) Wood pretreatment: Before impregnation, put the low-density poplar with a size of 20cm×10cm×3cm into an oven at 65° C. to dry until the moisture content is less than 10%.

[0058] (2) Take out the dried poplar wood in step (1), put it in the dipping tank, adjust the pressure inside the tank to a negative pressure of -0.09MPa, and keep it for 2 hours. Then inject silica sol with a solid content of 25% into the tank and fill the tank, then adjust the pressure inside the tank to 1.0 MPa, and keep it for 6 hours, so that the silica sol solution can fully enter the interior of the wood. Release the pressure and drain the excess silica sol solution in the tank.

[0059] (3) Take out the poplar wood impregnated with the silica sol solution in step (2), and put it into an oven with a temperature of 65° C. to dry until the moisture content is less than 10%.

[0060] (4) Take out the dried poplar wood in step (3), put it in the dipping tank, adjust the pressure in the tank t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com