Mechanical mold spraying device

A technology of spraying equipment and molds, which is applied to coatings, spray booths, spraying devices, etc., can solve the problems of poor spraying quality, low work efficiency, inconvenient use, etc., and achieve the effect of simple operation, convenient use and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

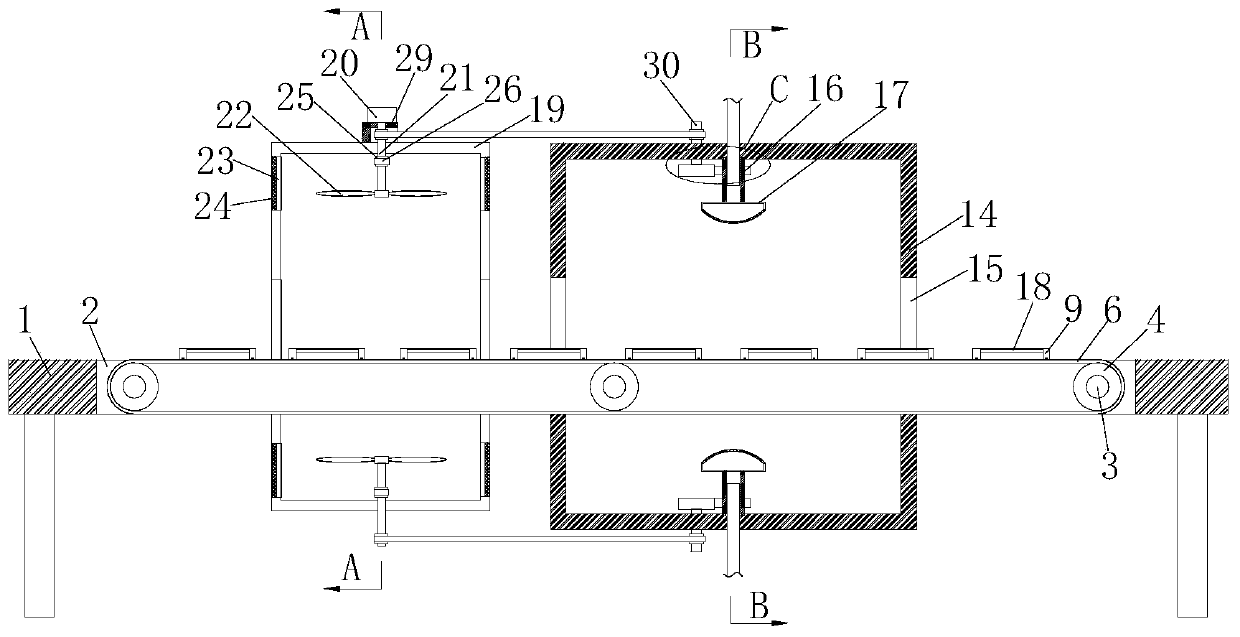

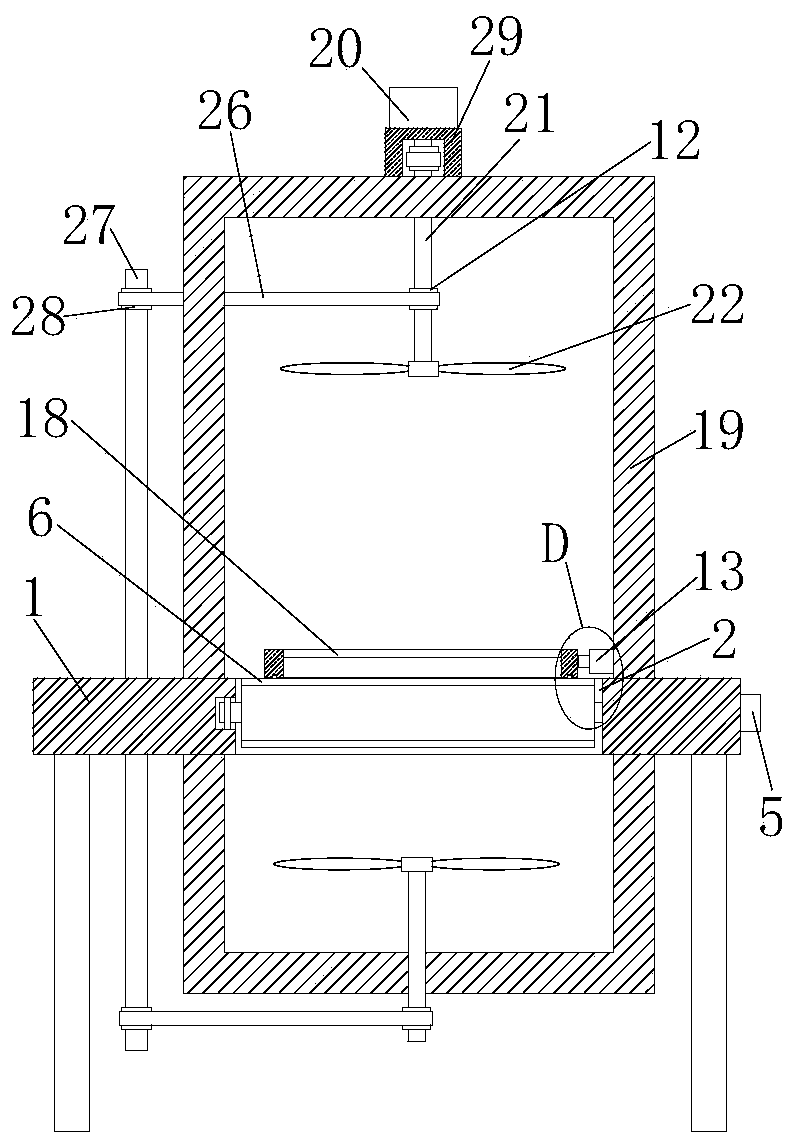

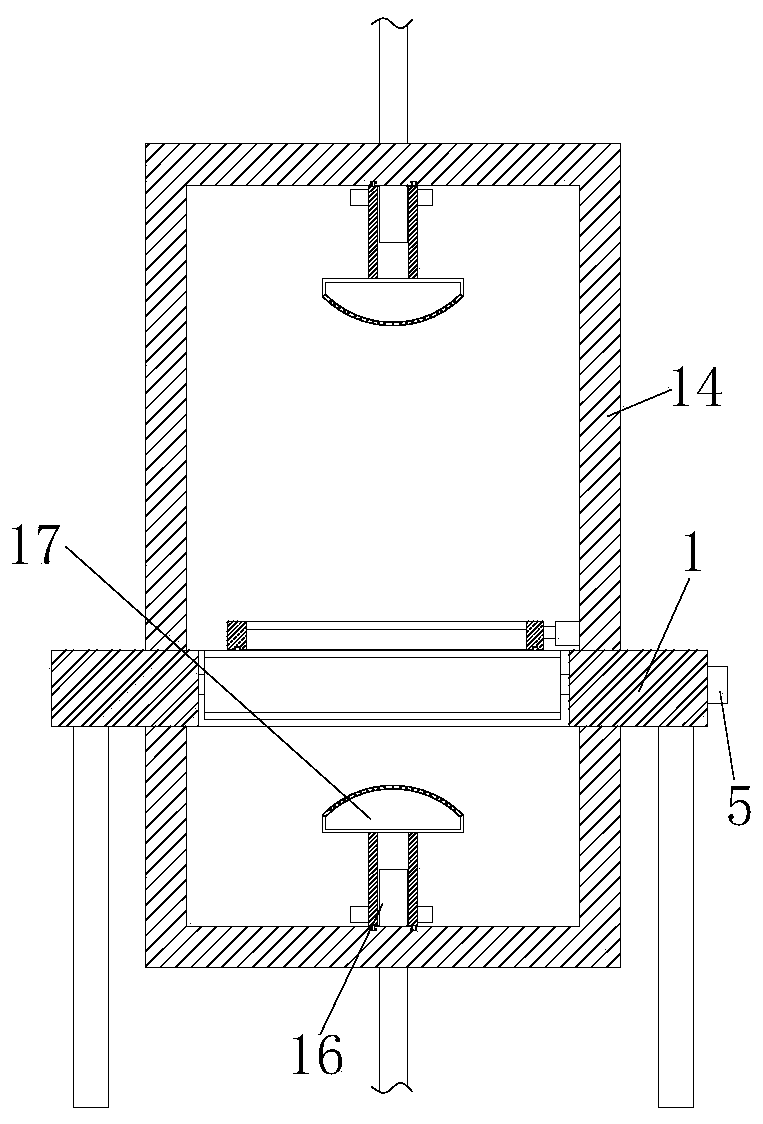

[0030] refer to Figure 1-6 , a kind of mechanical mold spraying equipment, comprising an operation table 1, a transmission hole 2 is opened on one side of the operation table 1, three rotating shafts 3 are rotatably connected to the inner wall of the transmission hole 2, and a first motor is fixedly installed on one side of the operation table 1 5. The output shaft of the first motor 5 is fixedly connected to the corresponding rotating shaft 3. The outer fixed sleeve of the rotating shaft 3 is provided with a transmission wheel 4. The three transmission wheels 4 are connected to two conveyor belts 6, and the two conveyor belts 6 are fixed. A plurality of positioning rods 7 are installed, and the top of the positioning rod 7 is fixedly equipped with two symmetrically arranged fixed rods 8. On the operating table 1, a spraying box 14 and an air-drying box 19 are fixedly installed. On the top inner wall and the bottom inner wall of the spraying box 14 Both are rotatably connecte...

Embodiment 2

[0041] refer to Figure 1-6 , a kind of mechanical mold spraying equipment, comprising an operation table 1, a transmission hole 2 is opened on one side of the operation table 1, three rotating shafts 3 are rotatably connected to the inner wall of the transmission hole 2, and a first motor 5 is welded on one side of the operation table 1 , the output shaft of the first motor 5 is fixedly connected to the corresponding rotating shaft 3, and the outer fixed sleeve of the rotating shaft 3 is provided with a transmission wheel 4, and two transmission belts 6 are connected to the three transmission wheels 4, and two transmission belts 6 are welded between A plurality of positioning rods 7, the top of the positioning rod 7 is welded with two symmetrically arranged fixed rods 8, a spraying box 14 and an air-drying box 19 are welded on the operating table 1, and the top inner wall of the spraying box 14 is connected with the bottom inner wall in rotation. The water guide pipe 16 is rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com