Magnetic expansion coil winding power mechanism

A braking force and coil technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as loosening and shifting of the skeleton, loosening and slipping of the skeleton of the conductor coil, and low integration of the device, so as to improve the use of Longevity and stability, prevention of skeleton loosening and displacement, stable and reliable fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described in conjunction with the following examples.

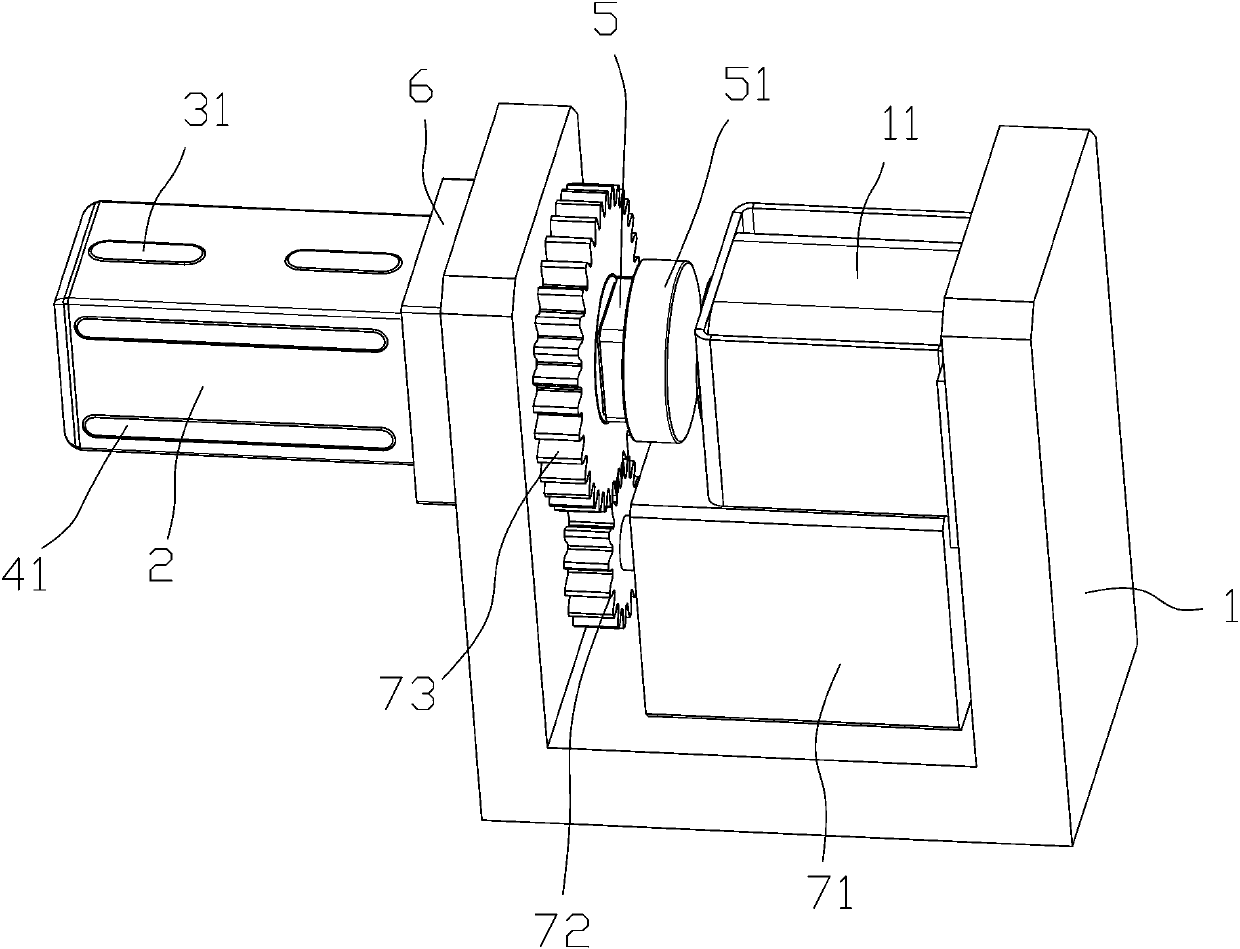

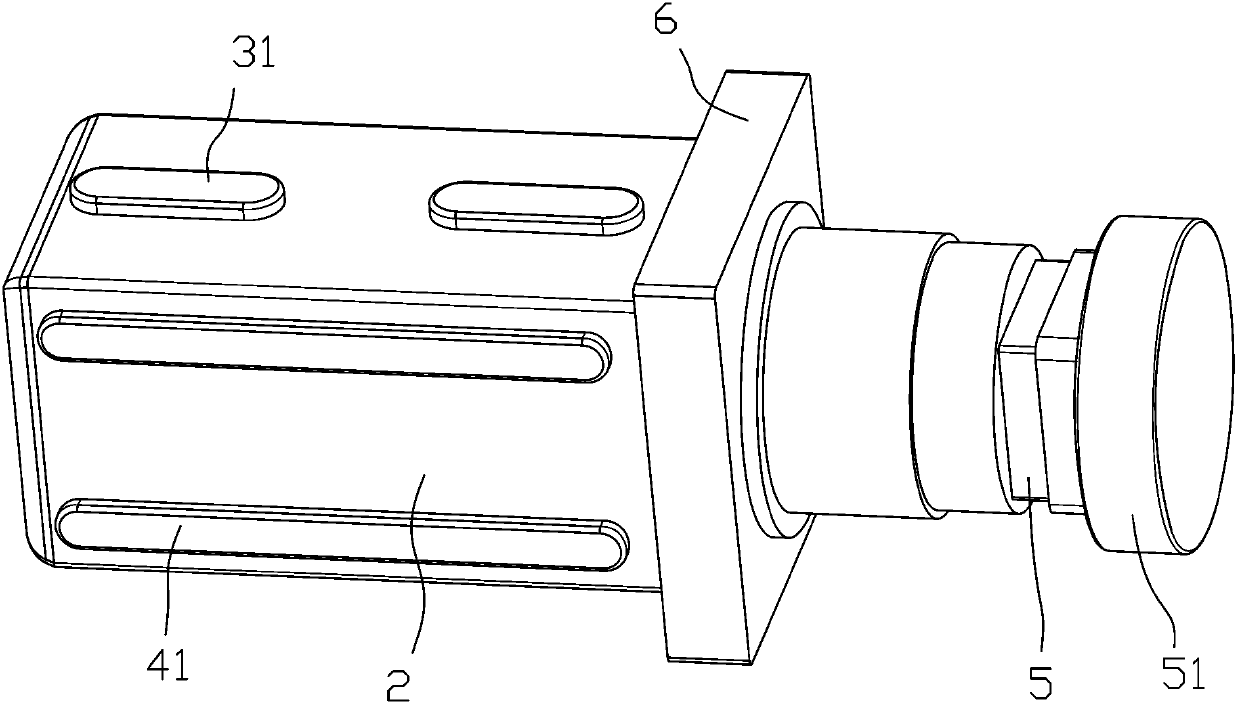

[0021] Depend on Figure 1 to Figure 4 It can be seen that a magnetic expansion coil winding braking power mechanism described in this embodiment includes a bracket 1, an electromagnet 11 fixed on the bracket 1, a rotating expansion shaft 2 located on the bracket 1, and a driving shaft for driving the expansion shaft. 2 rotating rotating components;

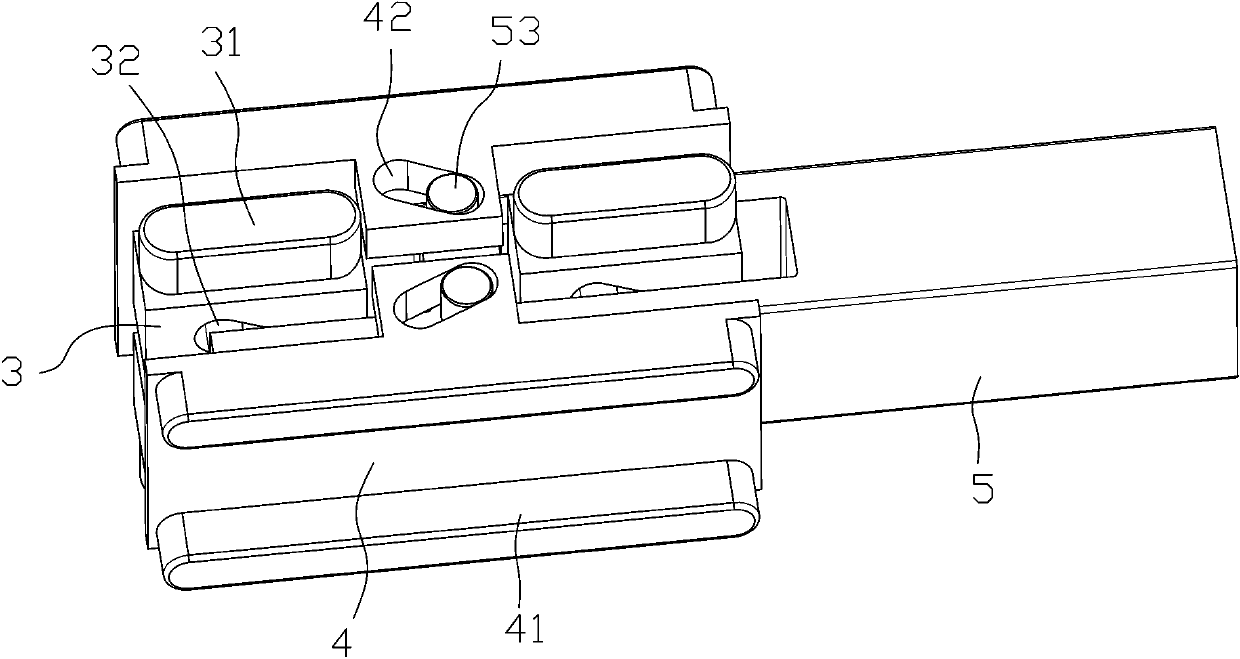

[0022] The first expansion plate 3 is movable on both sides of the upper and lower sides of the expansion shaft 2; the second expansion plate 4 is movable on the left and right sides of the expansion shaft 2; the first expansion plate 3 And the second expansion plate 4 moves along the radial direction of the expansion shaft 2;

[0023] The expansion shaft 2 is movable and provided with an expansion block 5 for driving the first expansion plate 3 and the second expansion plate 4 to move; the expansion block 5 moves along the axial dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com