Skin stripping device for wire and cable recycling

A wire and cable and stripping device technology, applied in recycling technology, electronic waste recycling, circuits, etc., can solve the problems of inability to effectively limit the cable, low cable stripping efficiency, and no winding function. Avoid jittery shift effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

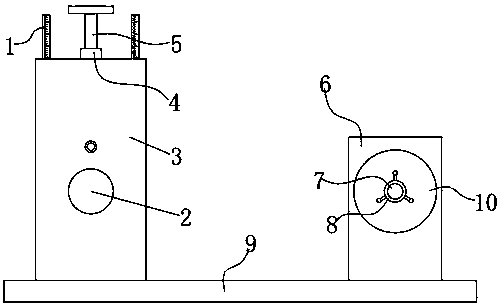

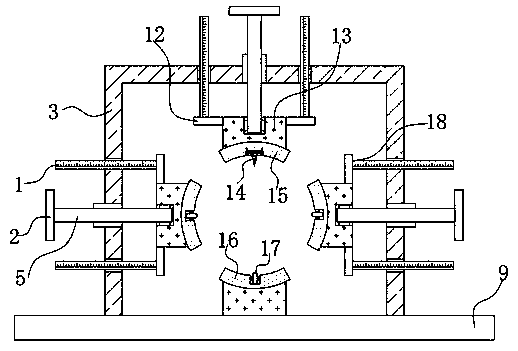

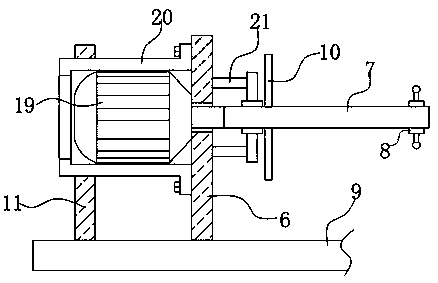

[0026] refer to Figure 1-4 , a skin peeling device for wire and cable recovery, including a base plate 9, three equidistant circularly distributed peeling mechanisms 18 and a winding mechanism, the three peeling mechanisms 18 and the lower arc seat 16 limit the space of the cable, to avoid the cable from peeling When shaking and shifting, the top outer wall of the bottom plate 9 is welded with a U-shaped plate 3, and the outer walls on both sides and the top of the U-shaped plate 3 are provided with round holes and two via holes. Three peeling mechanisms 18 are distributed on the U-shaped plate 3 The two sides and the top of the strip, the peeling mechanism 18 includes a round tube 4, the round tube 4 is welded in the round hole, the inner wall of the round tube 4 is threadedly inserted with a threaded rod 5, the end of the threaded rod 5 is welded with a handle 2, the threaded rod 5. One end away from the handle 2 is connected with a connecting seat 13 through a bearing rota...

Embodiment 2

[0035] refer to Figure 5, a skin peeling device for electric wire and cable recovery, the main difference between this embodiment and embodiment 1 is that in this embodiment, the top outer wall of the bottom plate 9 is welded with a support plate 22, and the side wall of the support plate 22 has a fixing hole, The inner wall of the fixing hole is welded with a transverse tube 23, and the transverse tube 23 is located between the U-shaped plate 3 and the winding mechanism.

[0036] When in use, one end of the cable is passed through the horizontal tube 23 and then wound on the winding core. The horizontal tube 23 can guide the cable and reduce the vibration of the cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com