Method for customizing personalized ceramic cup

A technology of ceramic cups and molds, which is applied in the direction of manufacturing computing systems, data processing applications, sales/lease transactions, etc., can solve the problems of high cost and low efficiency, and achieve high work efficiency, rapid production, and low cost of mold opening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

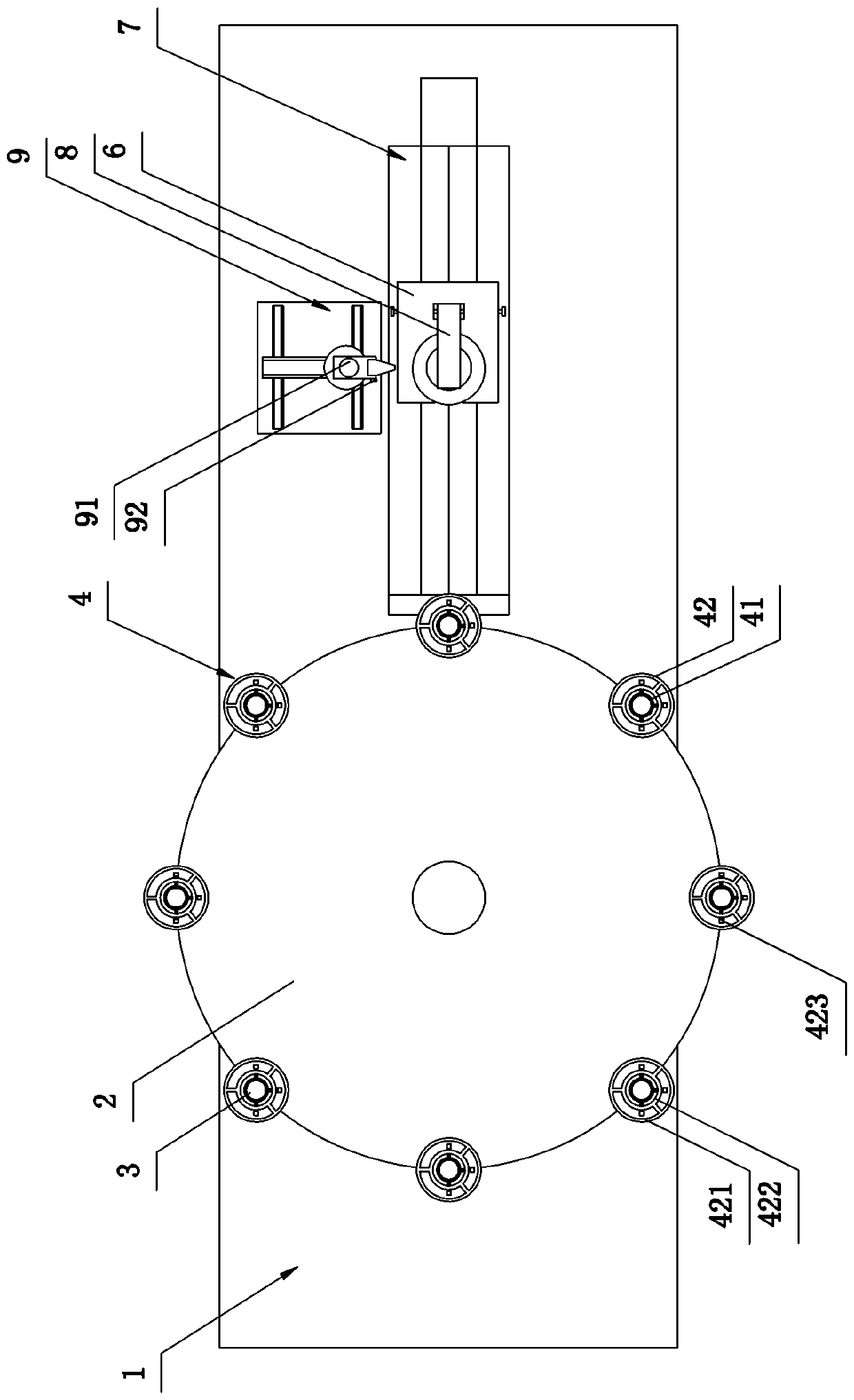

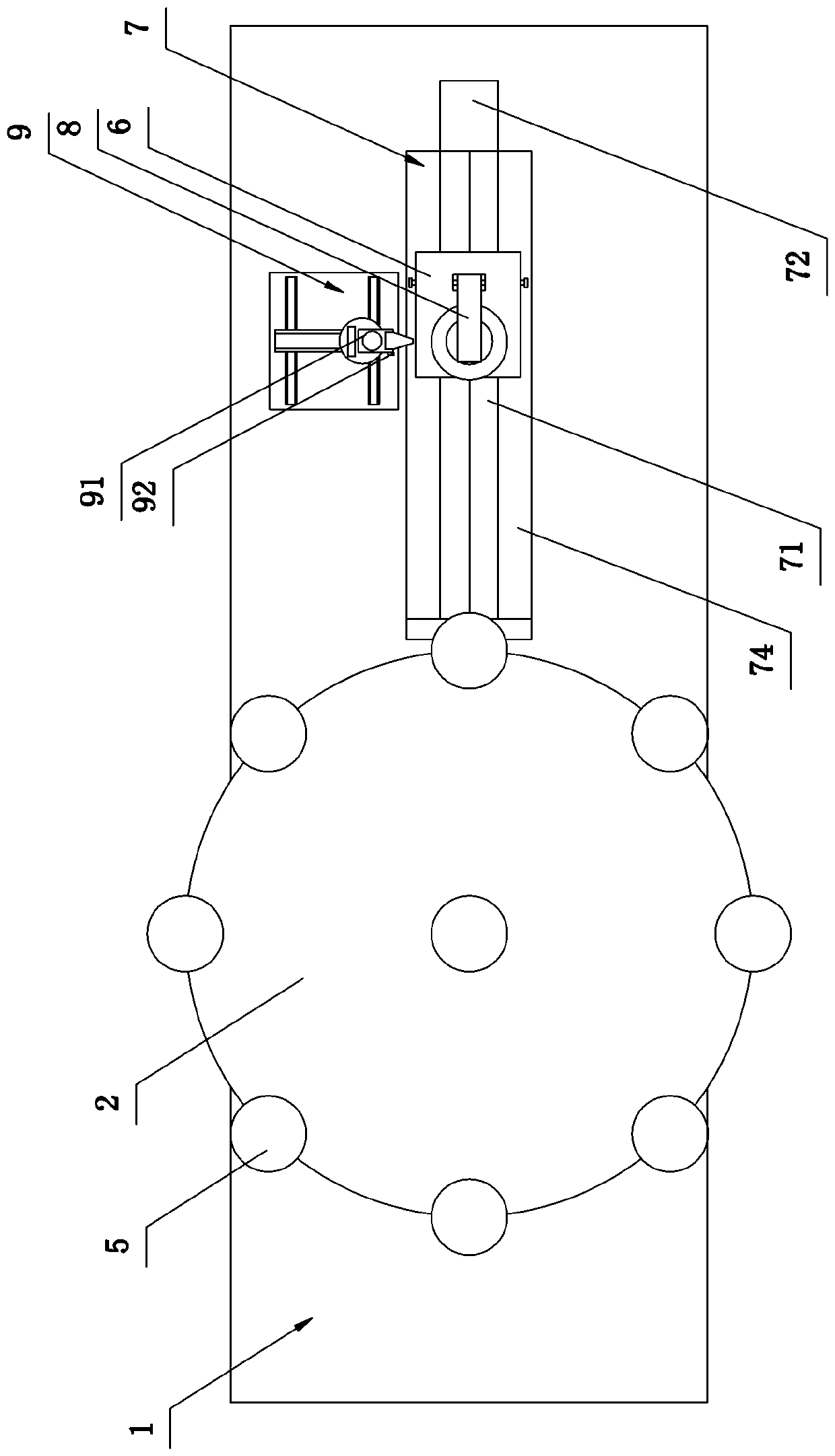

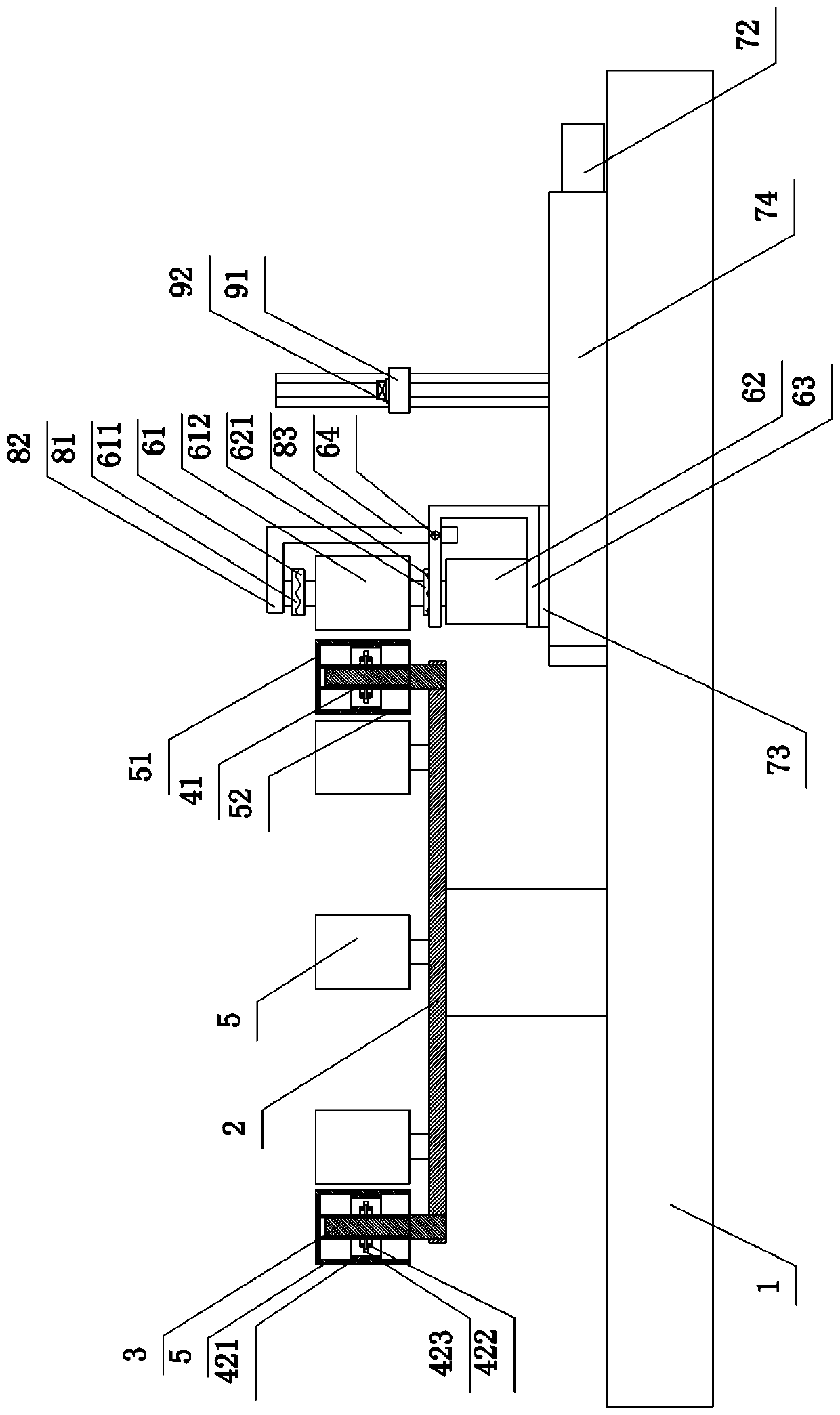

[0026] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0027] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 . A method for customizing a personalized ceramic cup, comprising the following steps:

[0028] 1) The user selects the required ceramic cup pattern 100 in the database, submits a personalized label, and sets the position of the personalized label relative to the ceramic cup pattern 100 to complete the order;

[0029] 2) According to the order information, the manufacturer takes out the stamp 61 having the pattern 100 corresponding to the ceramic cup, and installs the stamp 61 on the rotary carving mechanism 6;

[0030] 3) The manufacturer uploads the order information to the visual 3D printing device 9;

[0031] 4) After the visual 3D printing device 9 recognizes the personalized label and the position of the personalized label relative to the ceramic cup pattern 100, it autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com