Overlying strata aquifer-oriented isolation coal pillar and gasification furnace width design method for underground gasification

A technology of underground gasification and gasifier, which is used in design optimization/simulation, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with figure and specific implementation process:

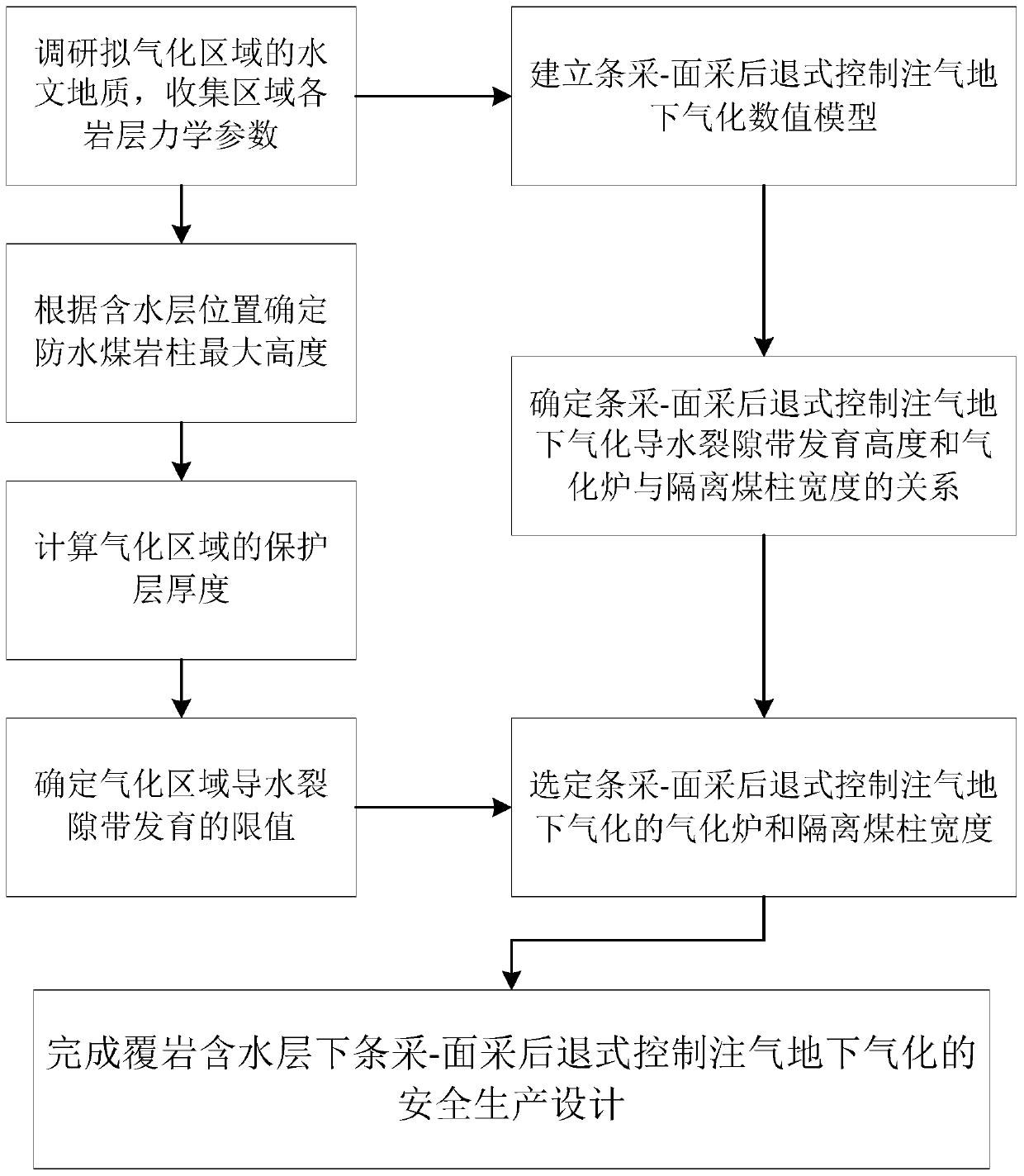

[0028] As shown in Figure 1, the method for designing the width of the isolated coal pillar and the width of the gasifier for underground gasification under the overburden aquifer is as follows:

[0029] a. Determine the maximum height of the waterproof coal rock pillar according to the hydrogeological data of the gasification area and the location of the aquifer;

[0030] b Use the calculated thickness of the protective layer to determine the limit value of the development of water-conducting fractured zones in gasification coal mining in the study area;

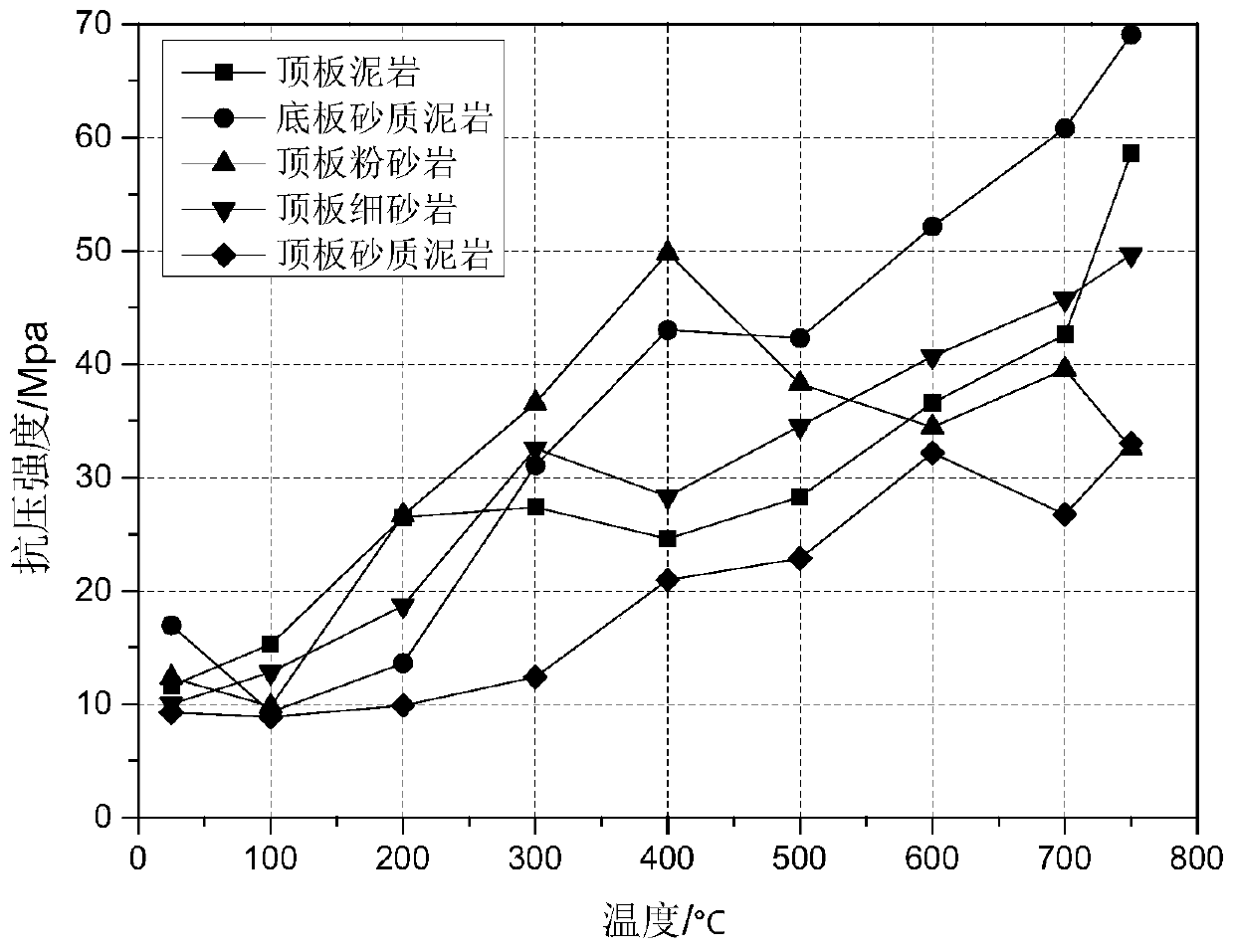

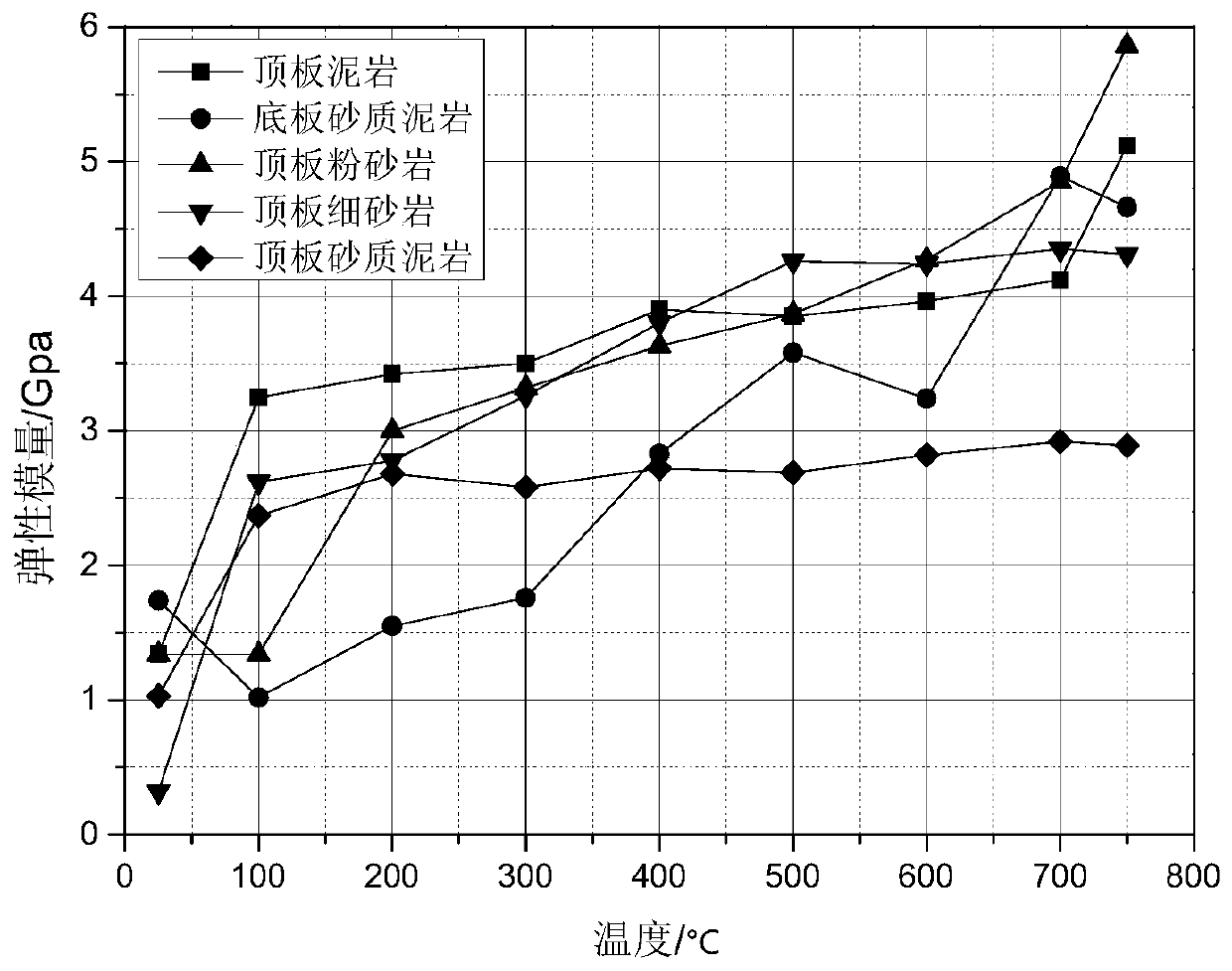

[0031] cUsing the collected geological data of the gasification area and the mechanical parameters of each rock formation, a numerical simulation model is established based on the numerical simulation method for underground gasification under the control of gas injection by strip mining an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com