Sewing machine oil supply unit

A technology for oil supply devices and sewing machines, which is applied to sewing machine components, sewing equipment, lubrication/cooling devices, etc., and can solve problems such as inconsistent fit clearances, oil leakage probability, and poor oil control accuracy in circulating oil circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with each accompanying drawing, the present invention is described in detail.

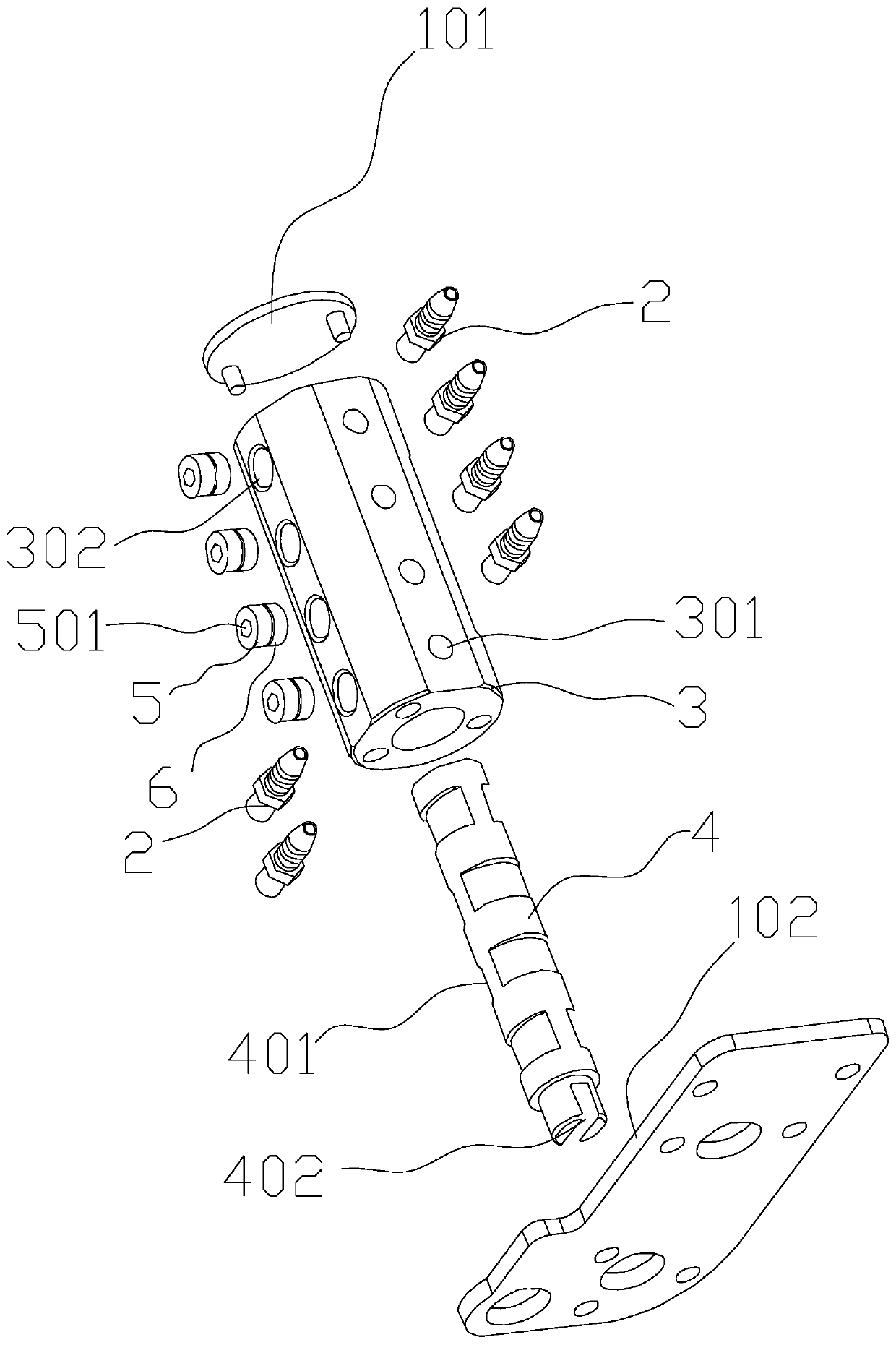

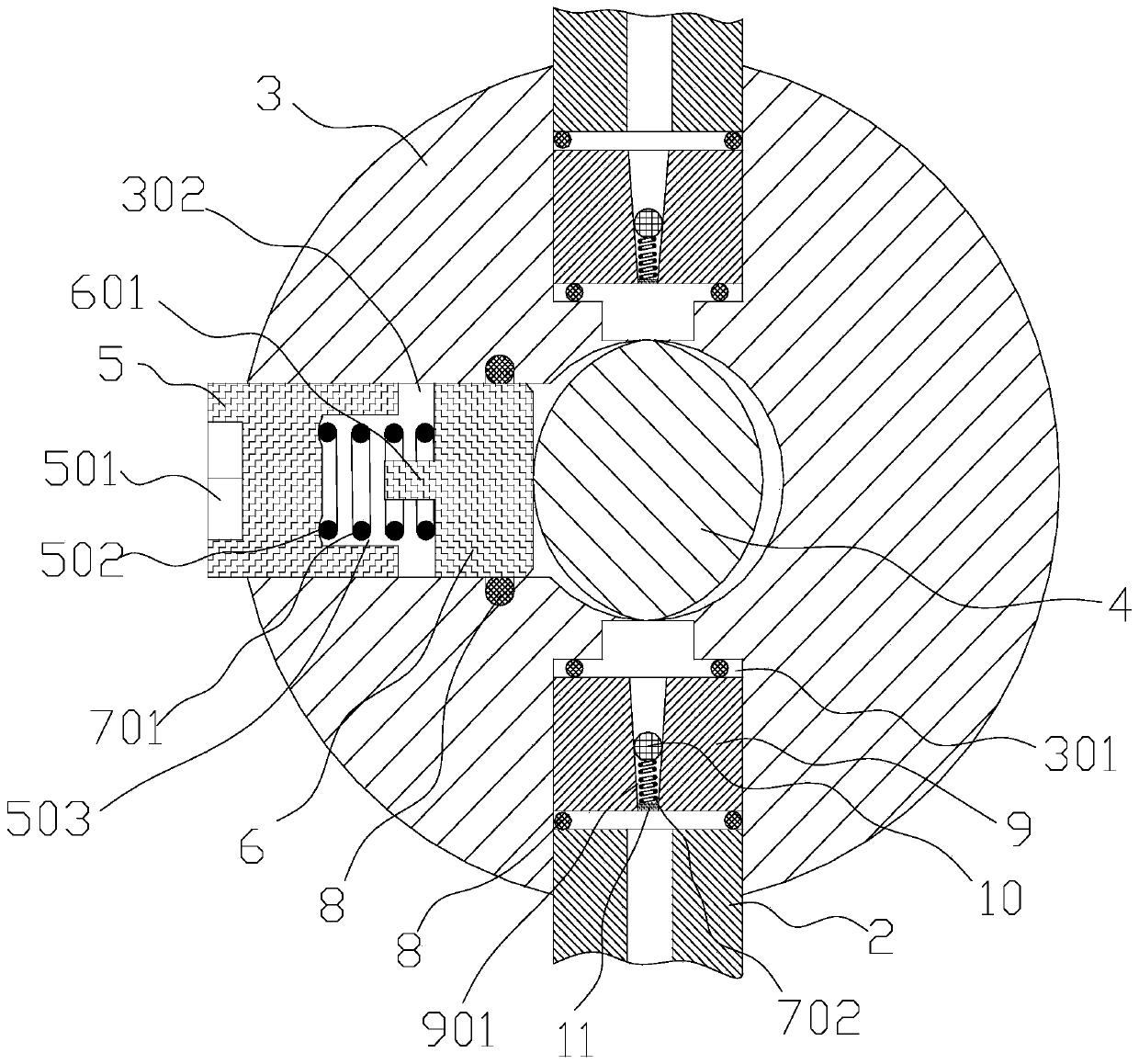

[0027] as attached figure 1 and attached figure 2 As shown, a sewing machine oil supply device includes a pump body 3, a rotating shaft 4, a joint 2, a first fixing plate 101 and a second fixing plate 102, and the first fixing plate 101 and the second fixing plate 102 can be detachably arranged on At the two ends of the pump body 3, the rotating shaft 4 is rotated and installed in the cavity formed by the pump body 3, the first fixed plate 101 and the second fixed plate 102, and the rotating shaft 4 runs through the first fixed plate 101, and the pump body 3 is provided with a connection Hole 301, joint 2 is installed on the connection hole 301, also includes column foot 6, column cover 5 and column spring 701, is provided with circular plug hole 302 on pump body 3, column foot 6 is circular column foot 6, column The cover 5 is a circular column cover 5, and the colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com