Hand-push loading and unloading container forklift

A technology of forklifts and push rods, applied in the direction of lifting devices, etc., can solve the problems of low loading and unloading efficiency, high degree of personnel participation, and inadequate transportation, etc., and achieve the effects of improving efficiency, simple structure, and convenient storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

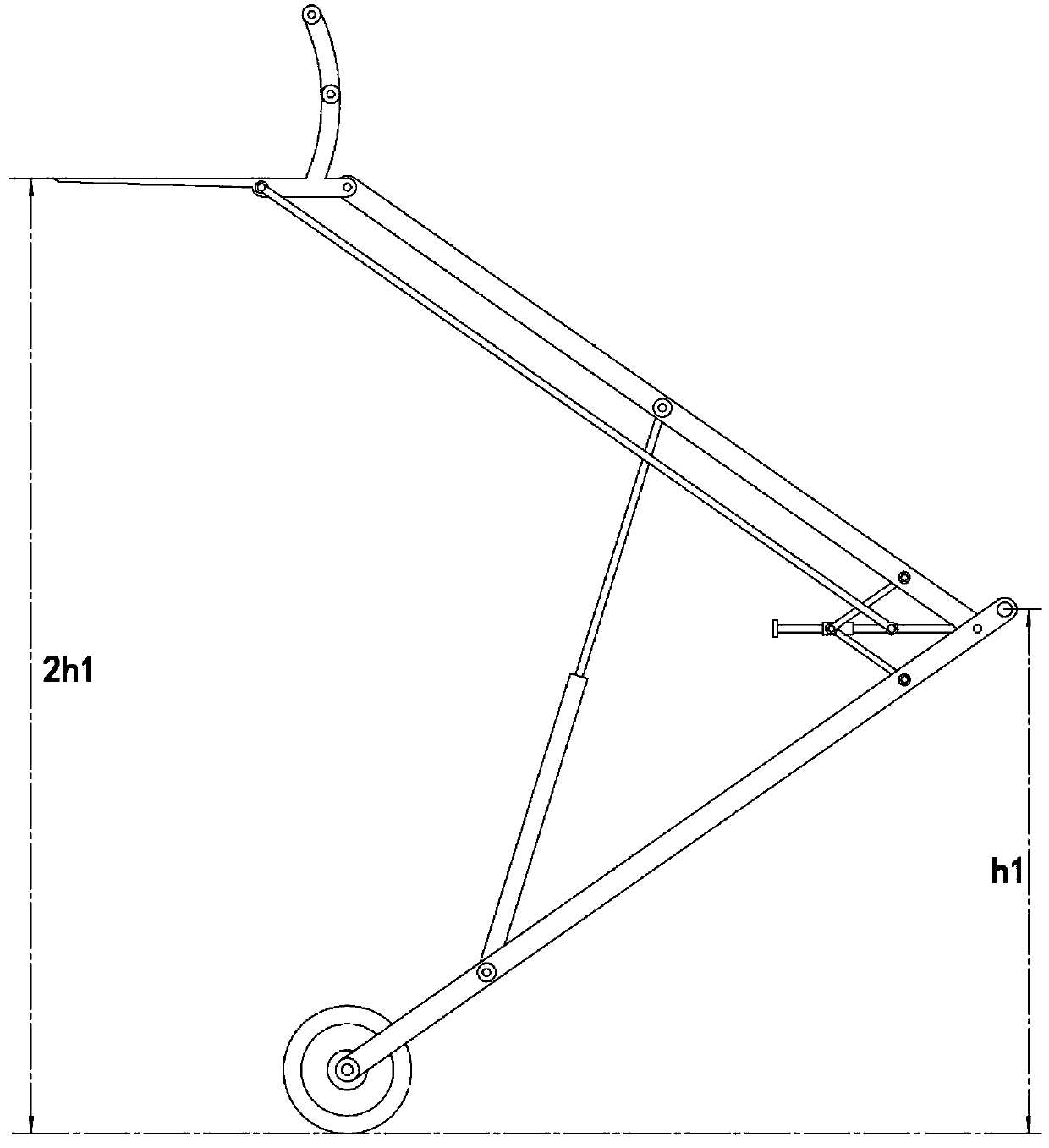

[0028] Embodiment 2: On the basis of Embodiment 1, an implementation that does not contain the balance restraint mechanism 3 is provided. At this time, the shovel frame is required to be fixed on the front end of the top frame instead of a hinged relationship. When operating the forklift, when the top frame When there is a change in height between 2 and the chassis 1, the angle of the bucket frame is not always horizontal, but will be tilted, tilted backward when it is at a high position, and tilted forward when it is at a low position, but when the loading and unloading height difference When it is not obvious, and when it is only used to transfer goods horizontally, or when the goods are not delicate and fragile items, although there is a slightly inclined shovel transport process in this embodiment, it will basically not cause the imbalance of the goods and will not affect the use. Effect.

Embodiment 3

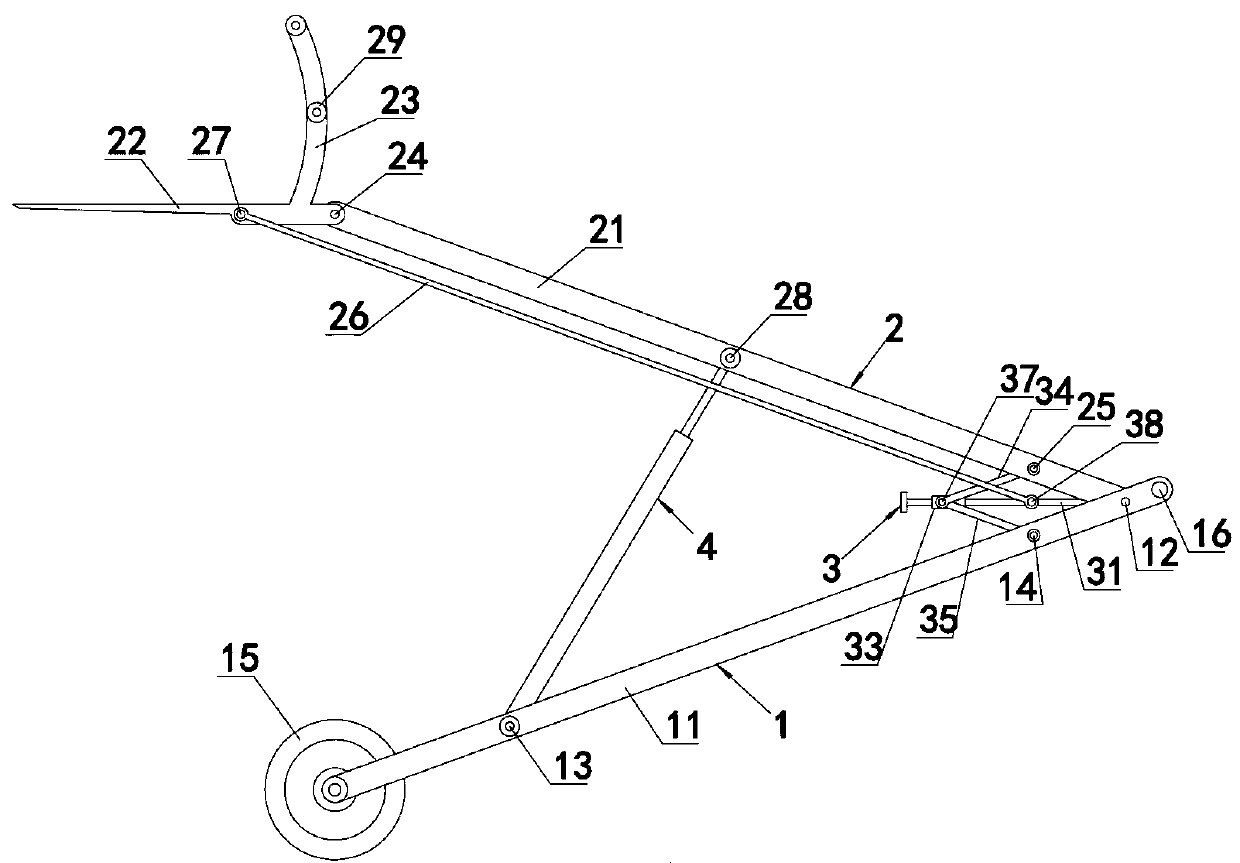

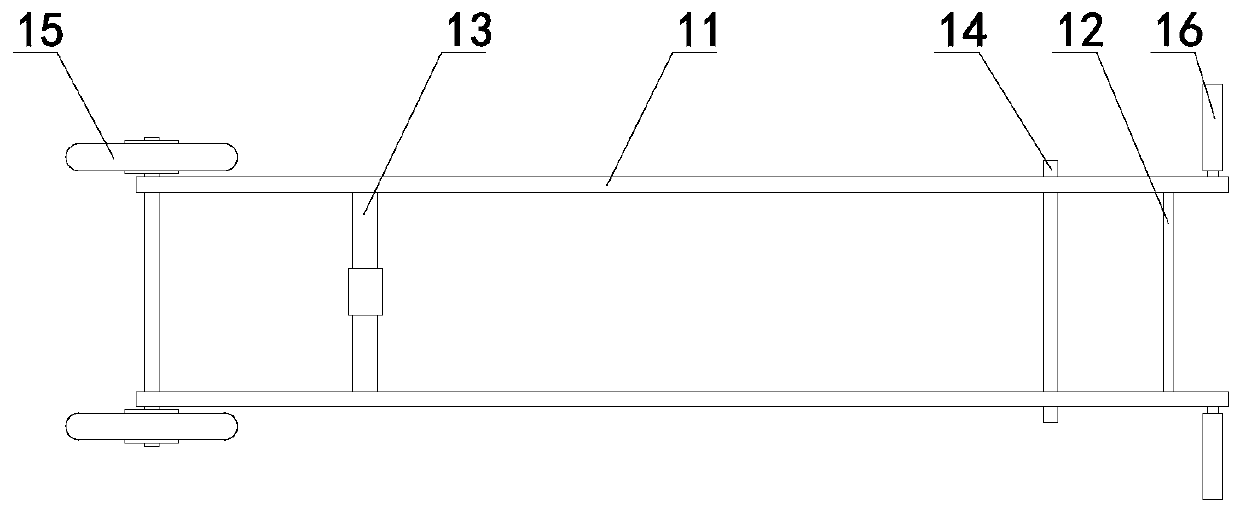

[0029] Embodiment 3: On the basis of Embodiment 1, although the balance restraint mechanism 3 is not used, the interlocking structure of the balance auxiliary rod 26 is adopted. This embodiment cannot always keep the bucket frame 22 level, but it can Linkage relationship, change the bucket frame 22 to eliminate the degree of inclination. Specifically, the front portion of the upper side bar 21 on both sides is hinged to the shovel frame 22 by the upper rotating shaft 24, and the outer side wall of the shovel frame 22 is vertically fixed with an upper pin shaft 27 on the auxiliary rod, and the lower side bar 11 on the two sides is vertically fixed. The inner side or the outer side of the rear portion is vertically fixed with the lower bearing pin 14 of balance, and the upper and lower ends of the balance auxiliary rod 26 are respectively hinged on the upper bearing pin 27 of the auxiliary rod and the lower bearing pin 14 of the balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com