Weak-rigidity thin-wall composite component profile outline measuring system and method

A composite material component and measurement system technology, which is applied in the field of surface profile measurement system of weakly rigid thin-walled composite material components, can solve problems such as difficult to accurately measure the profile of weakly rigid thin-walled composite material components, and achieve convenient reuse, The effect of avoiding overall movement and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

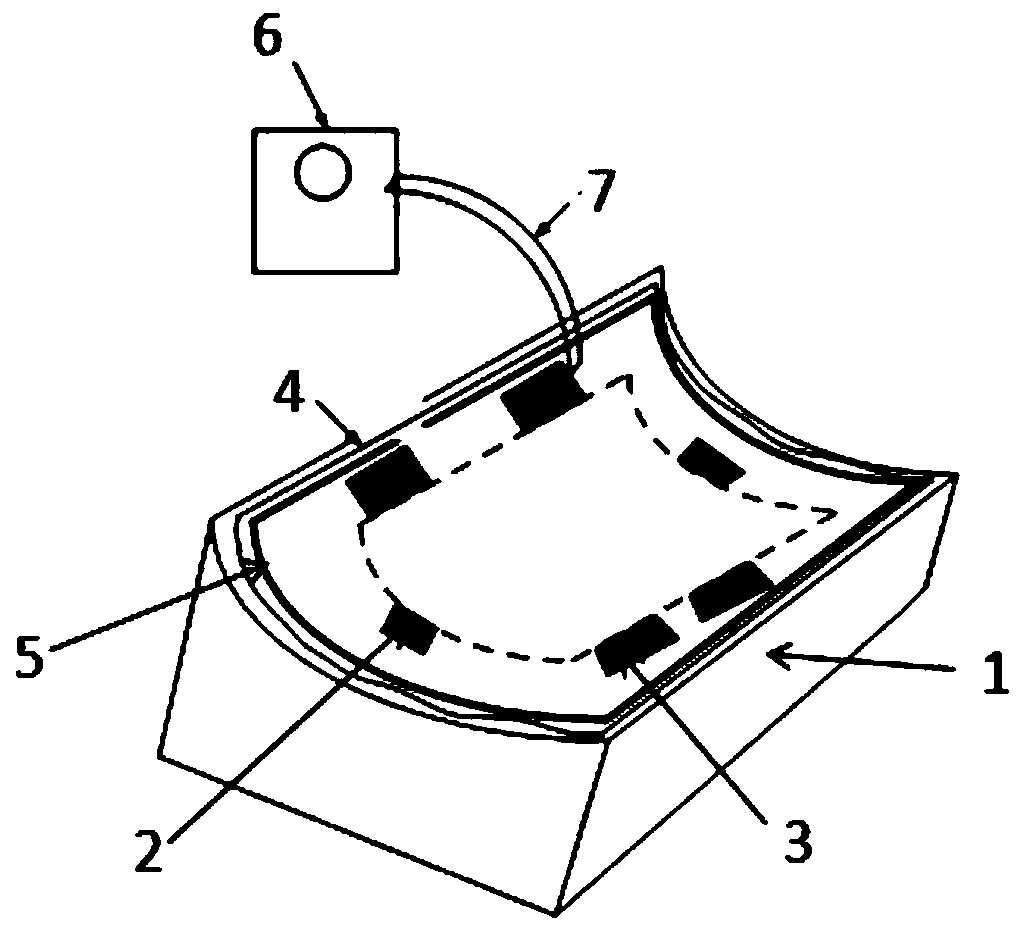

[0079] The surface profile measurement system and method of the weakly rigid thin-walled composite material component of the present invention are used to measure the profile of the heat-insulating tile with a special-shaped curved surface, and the heat-insulating tile is fixed on the mold unit, such as Figure 8 As shown, the punch 8 is used to correct and measure the inner surface of the heat insulating tile, and the specific steps are as follows:

[0080] step 1:

[0081] The special-shaped curved surface heat insulation tile is a weakly rigid thin-walled composite material component. The heat insulation tile has a curved surface structure, and the surface contour deviation is required to be within the range of -0.2mm to +0.2mm.

[0082] According to the thermal insulation tile model diagram, such as Figure 7 As shown, a set of inspection molds is processed, including the punch 8 and the die 1. In this embodiment, the punch 8 is used to correct and measure the inner surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com