a wrench

A wrench and electric wrench technology, applied in the field of wrenches, can solve problems such as limited adjustment angle, inability to adapt to knife gate bolt tightening, inability to complete knife gate bolt tightening work, etc., to increase safety factor, high tightening efficiency, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

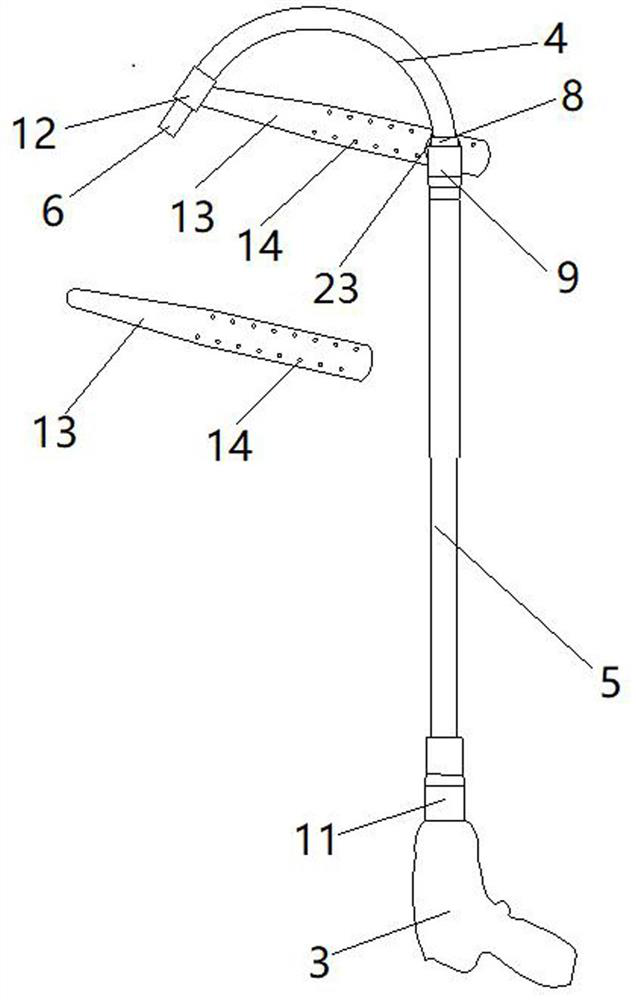

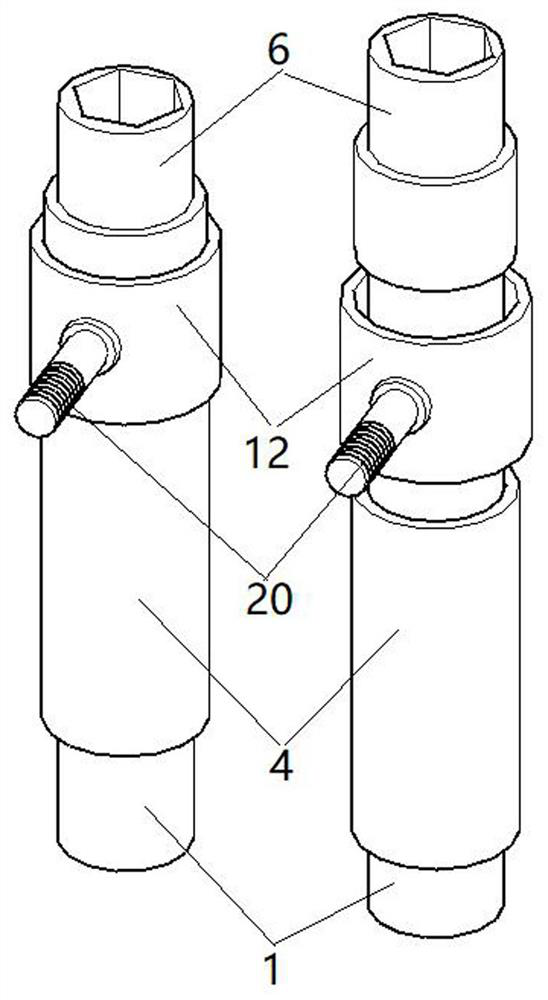

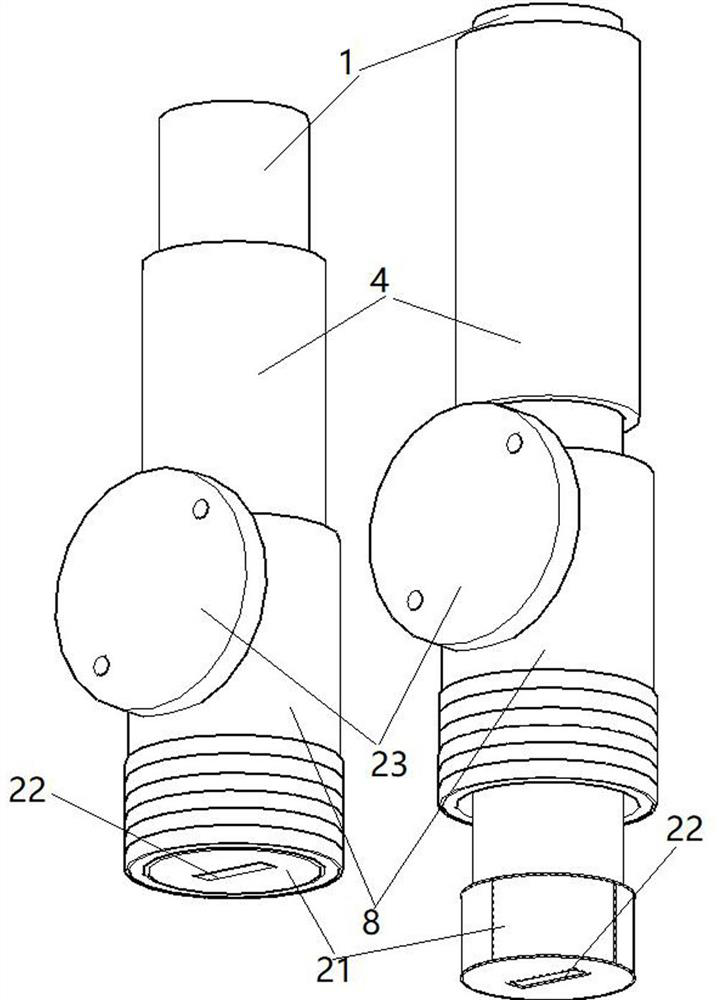

[0037] Such as Figure 1-6 Shown is the first embodiment of the present invention, an electric wrench, including a flexible shaft 1, a transmission shaft 2 and an electric wrench 3, the transmission shaft 2 is a steel round shaft, the flexible shaft 1 is sleeved with a sleeve 4, and the sleeve Tube 4 is an insulating hose made of rubber, such as figure 2 As shown, the sleeve head 6 is installed on the top of the flexible shaft 1 by welding or other means. The sleeve head 6 is a hexagonal socket head. You can prepare several more flexible shafts. The top of 4 press-fits the limit tube 12, the limit tube 12 is sleeved on the tail end of the sleeve head 6, and the bottom end of the flexible shaft 1 is welded with a steel cylinder-21, such as image 3 As shown, the center of the lower part of cylinder one 21 is cut with a cutting machine to form a keyway 22, cylinder one 21 and sleeve head 6 can be used as a limit assembly to prevent flexible shaft 1 from detaching from sleeve 4...

Embodiment 2

[0040] Such as Figure 7 Shown is the second embodiment of the present invention, the outer peripheral surface of cylinder one 21 is welded with bearing one 30, and the outer ring peripheral surface of bearing one 30 is welded in joint one 8; the outer peripheral surface of cylinder two 24 is welded with bearing two 31, bearing two 31 The outer peripheral surface of the outer ring is welded in joint two 9; the outer peripheral surface of cylinder three 26 is installed with welding bearing three 32 by means of glue, etc., the outer ring peripheral surface of bearing three 32 is welded in joint four 11, bearing one 30, bearing two 31 And bearing three 32 are tapered roller bearings.

Embodiment 4

[0044] Such as Figure 9 Shown is the fourth embodiment of the present invention, which is different from the first embodiment in that, due to the relatively high position of the equipment, two insulating rods 5 with drive shafts 2 inside need to be spliced together. The bottom end of transmission shaft 2 is welded with cylinder 3 26, the bottom end of cylinder 3 26 is welded with hexagonal rod 2 27, the top of drive shaft 7 located below is welded with cylinder 2 24, and the top surface of cylinder 2 24 is welded with a hexagonal sleeve matching hexagonal rod 2 27 Two 28, crimp joint four 11 at the bottom end of insulating rod 5 located above, crimp joint five 33 at the top of insulating rod 5 located below, joint five 33 is exactly the same as joint three 10, when splicing, insert hexagonal pole two 27 into the hexagon In the sleeve two 28, the joint five 33 is screwed into the joint three 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com