Vertical planting device and system

An equipment and vertical technology, applied in the fields of botanical equipment and methods, agricultural machinery and equipment, gardening tools/equipment, etc., can solve problems such as unstable transmission of planting racks, reduce high cost investment, improve anti-torsion force, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

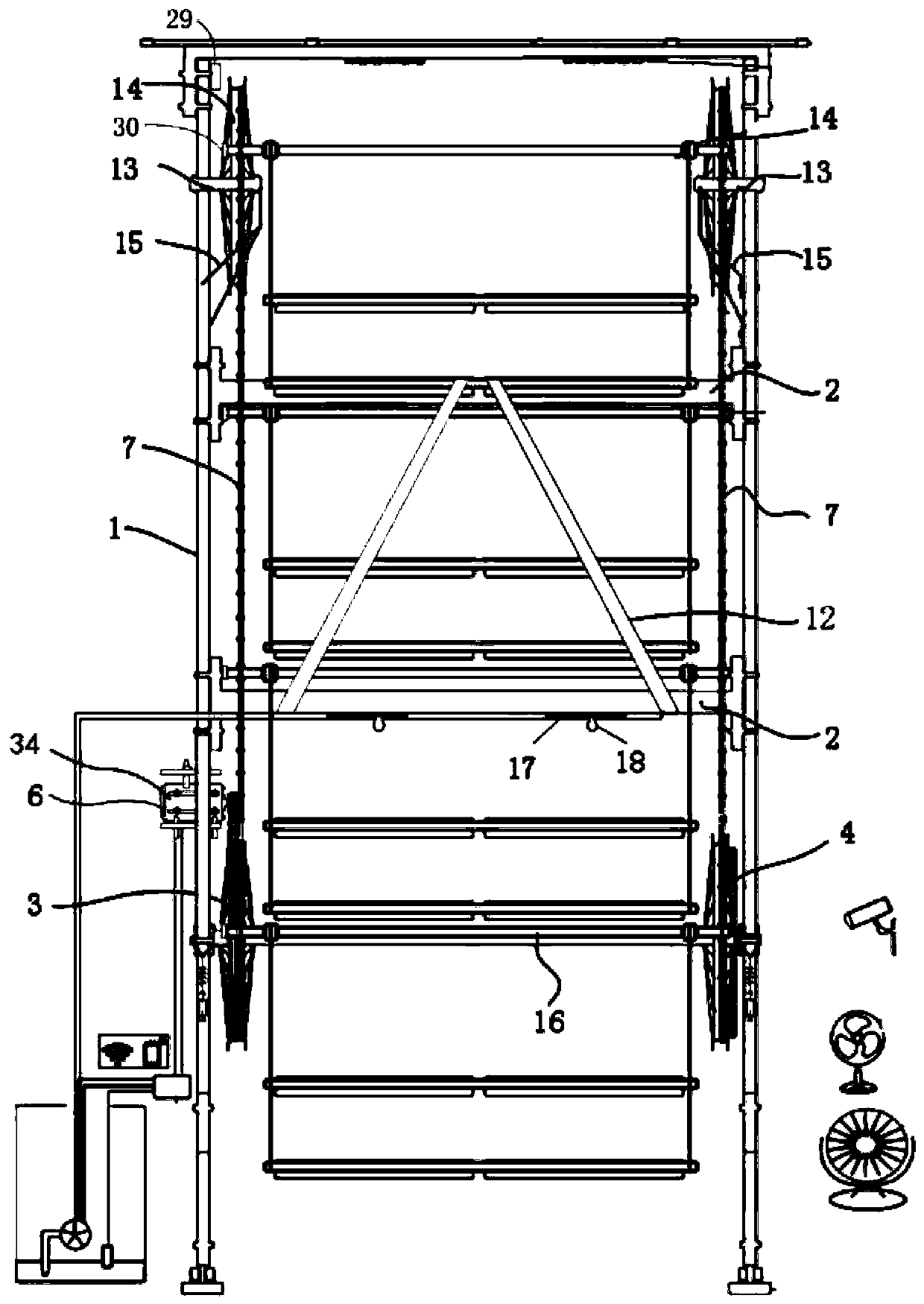

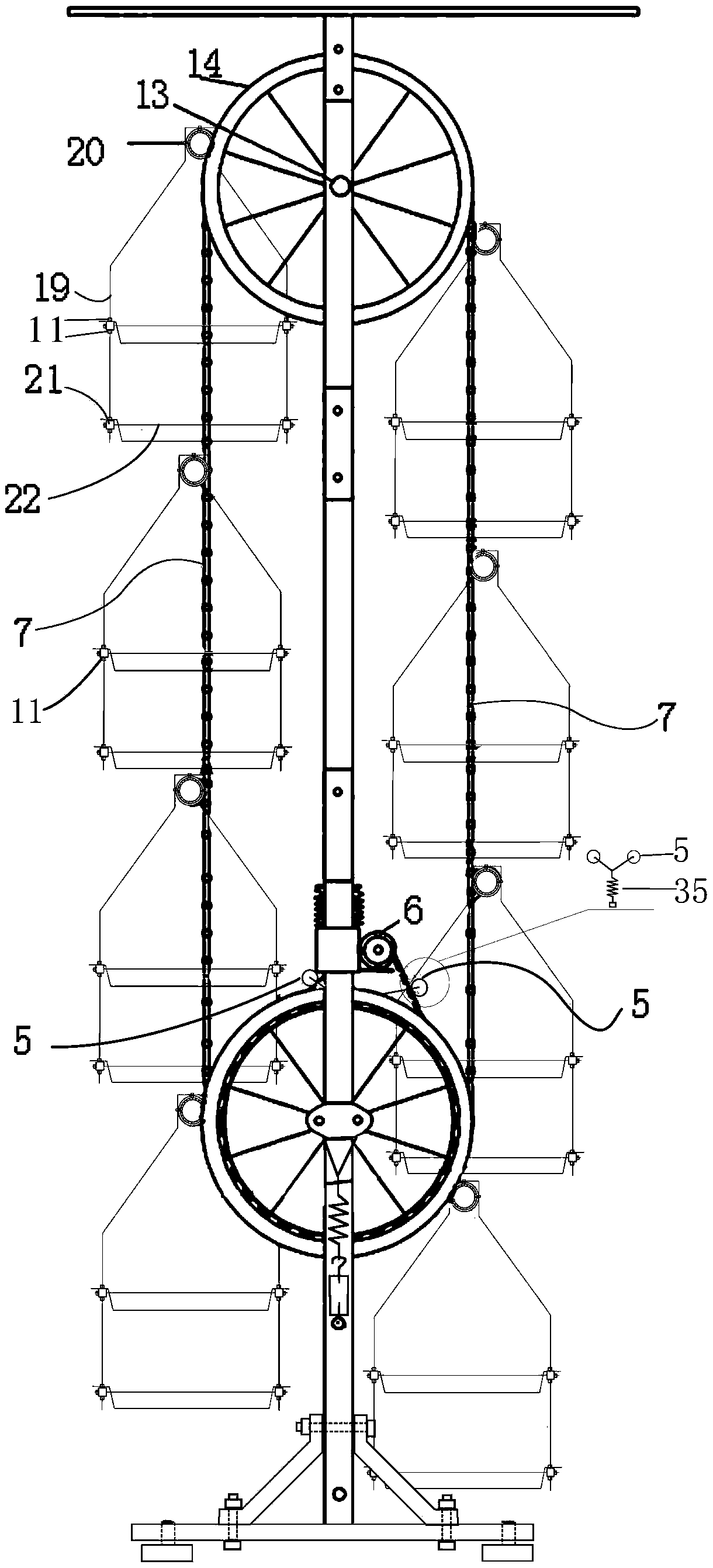

[0035] like Figure 1 to Figure 3As shown, a vertical planting device in this embodiment includes two columns 1, a plurality of beams 2, a first driving sheave 3, a second driving sheave 4, a driving shaft 16, a driving motor 6, and a transmission member 7. The driven shaft 13, the driven sheave 14 and the hanger assembly; the two columns 1 are vertically arranged on the horizontal plane, and a plurality of beams 2 connect the two columns 1; the first driving sheave 3 and the second driving The sheave 4 is fixed on the two ends of the drive shaft 16, and the two ends of the drive shaft 16 are rotatably connected to the lower end bearing seats of the two columns 1, and the top of each column 1 is rotatably connected to a driven shaft 13, and each driven Driven sheave 14 is all fixed on the shaft 13; The first driving sheave 3 is a double sheave, and the driving motor 6 is connected with a wheel groove transmission of the first driving sheave 3 through a transmission belt, and t...

Embodiment 2

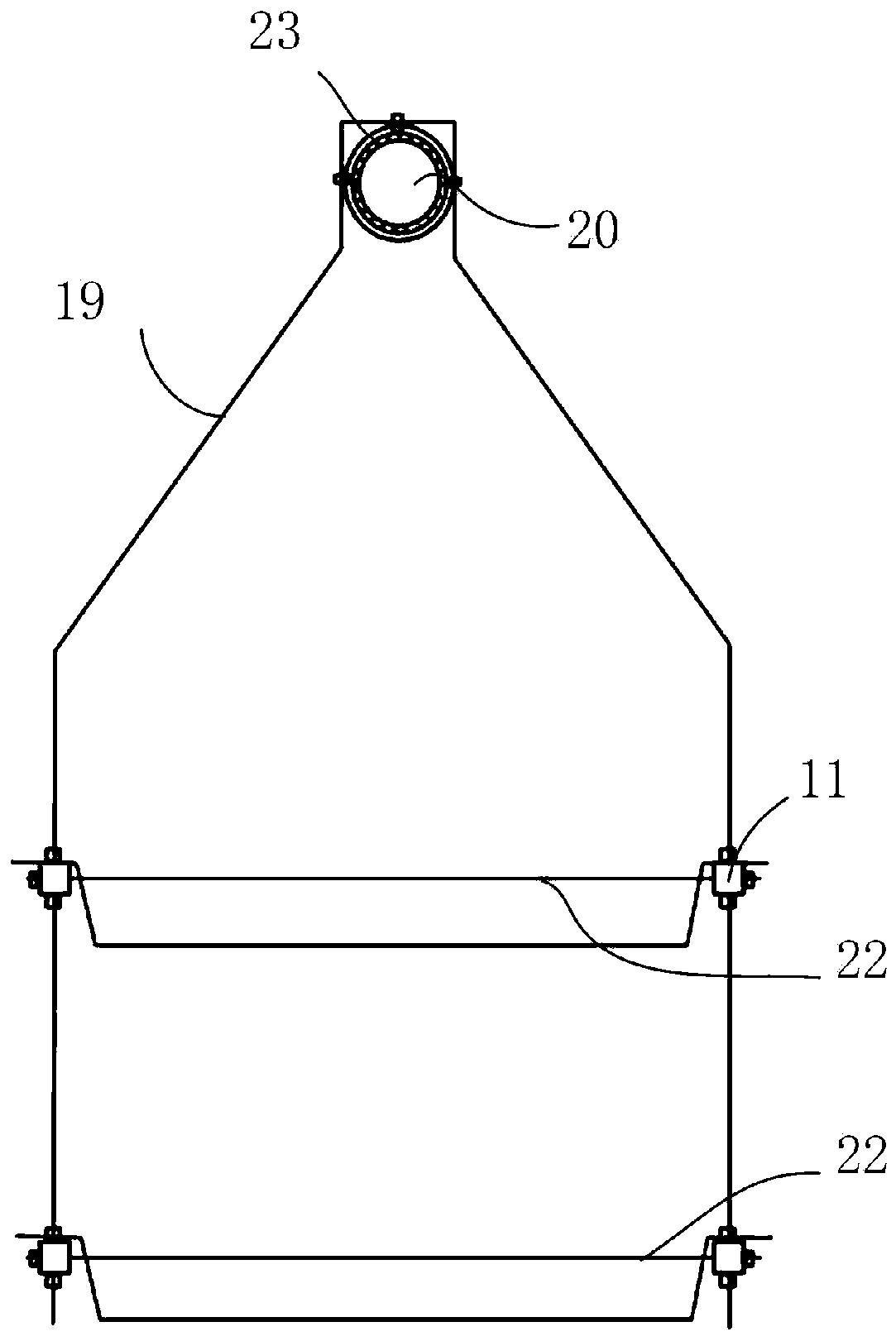

[0038] like Figure 2 to Figure 5 As shown, a vertical planting equipment in this embodiment includes all the technical features in Embodiment 1. In addition, the hanger assembly includes a hanger rod 20, an aluminum sleeve 11, a suspension bearing 23, and a planting tray hanger 19. Planting tray support rod 21 and anti-bias steel wire 22; the bearing capacity in the middle of the suspension rod 20 is the weakest, and the middle load of the suspension rod 20 is easy to bend and deform. The outer peripheral side is fastened by a hoop clamp, and the hoop clamp is bound with a planting tray hanger 19 through an iron wire. A plurality of planting tray hangers 19 are tightly connected to the planting tray support bar 21 with an aluminum sleeve 11, and the aluminum sleeve 11 is used for planting. Adjust the position of the tray support rod 21 up and down and increase or decrease the installation quantity of the plant tray support rod 21. The axis of the plant tray support rod 21 and...

Embodiment 3

[0042] like Image 6 As shown, a kind of vertical planting equipment in this embodiment includes all the technical features in Embodiment 2. In addition, the transmission member 7 is an annular closed synchronous belt 25, and the wheel groove of the first driving sheave 3 A plurality of short racks 24 are respectively fixed in the wheel grooves of the center and the second driving sheave 4, and a plurality of timing belt teeth are arranged on the short racks 24, and a plurality of short racks 24 on the first driving sheave 3 The circular arrays at equal intervals are fixed, and the plurality of short racks 24 on the second driving sheave 4 are fixed at equal intervals in an array; the outer peripheral side of the synchronous belt 25 is provided with a plurality of rubber seats 26, and the two ends of the boom 20 are inserted into the two In the rubber seat 26 of a synchronous belt 25, a round hole is arranged in the middle of the rubber seat 26, and the two ends of the suspens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com