Reworking device and method of display unit module

A display part and adhesive part technology, which is applied in the direction of identification devices, instruments, electronic waste recycling, etc., can solve problems such as unusable, damaged display part modules, and application of physical force, so as to achieve easy separation, minimize damage, and improve The effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, an apparatus and method for reworking a display unit module according to an embodiment of the present invention will be described with reference to the accompanying drawings.

[0035] In this process, the thickness of lines or the size of constituent elements shown in the drawings may be exaggerated for clarity and convenience of description. In addition, terms described below are terms defined in consideration of functions in the present invention, and may vary depending on users, operators' intentions, or customary practices. Therefore, the definition of such terms should be based on the entire contents of this specification.

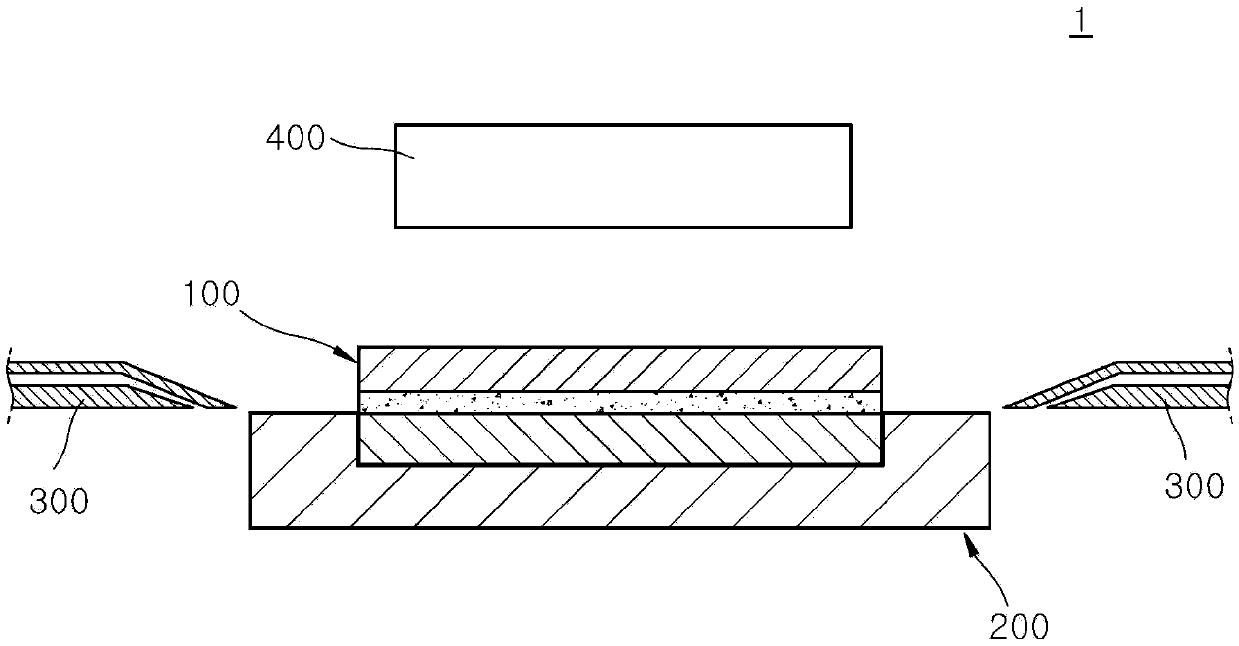

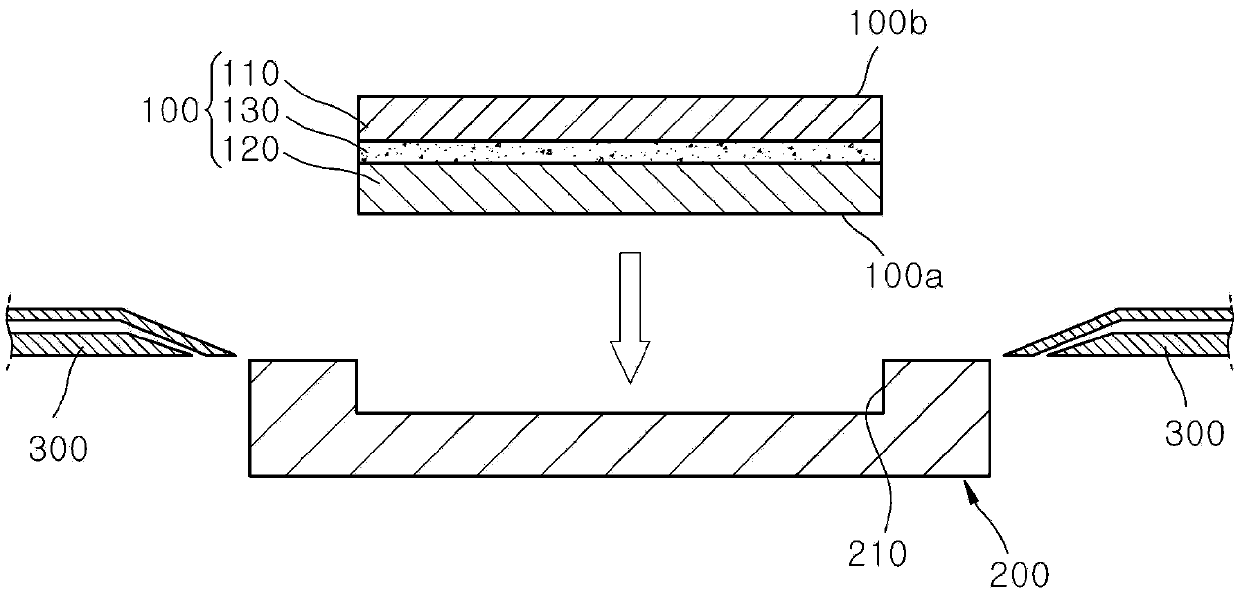

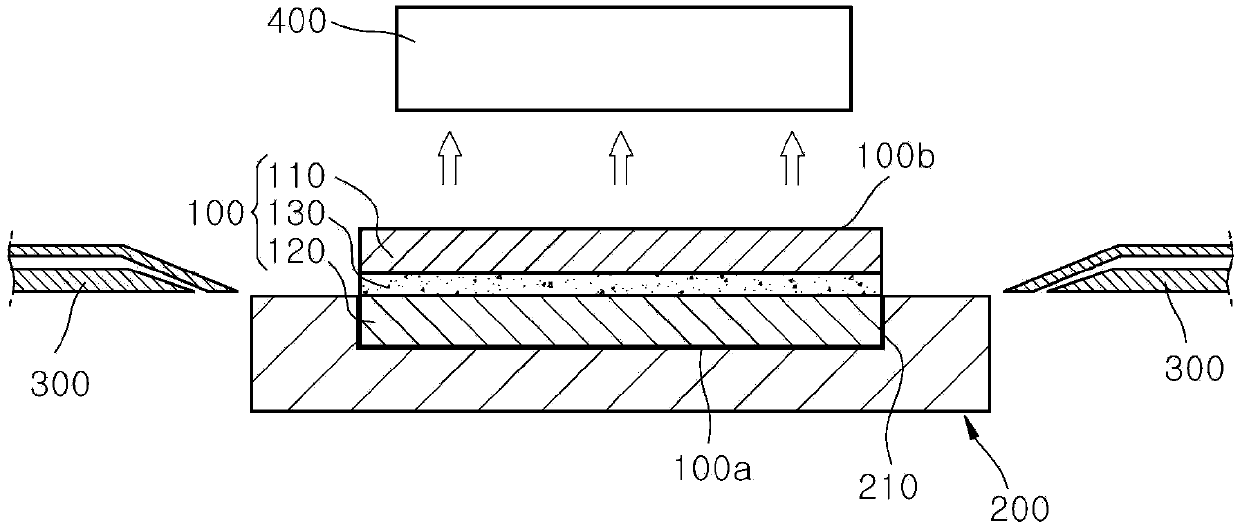

[0036] figure 1 is a perspective view of a rework device for a display module according to an embodiment of the present invention, figure 2 It is a schematic diagram of the display unit module installed in the temperature adjustment unit of the rework device of the display unit module according to an embodiment of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com