Fire cover for gas stove

A gas stove and fire cover technology, which is applied in the burner, combustion method, combustion type and other directions, can solve the problems of not using, easy to cause flame separation, poor heating effect at the center of the bottom of the pot, etc., and achieves good flame stabilization effect. The effect of low flame height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

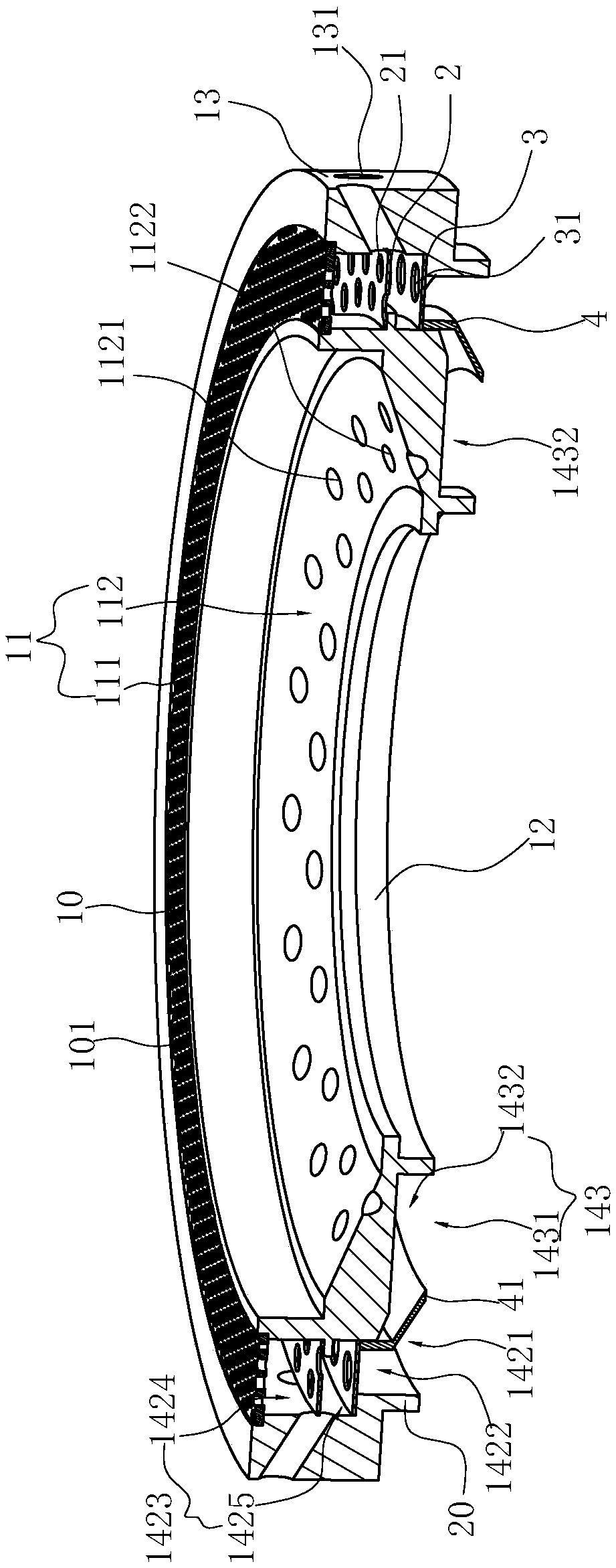

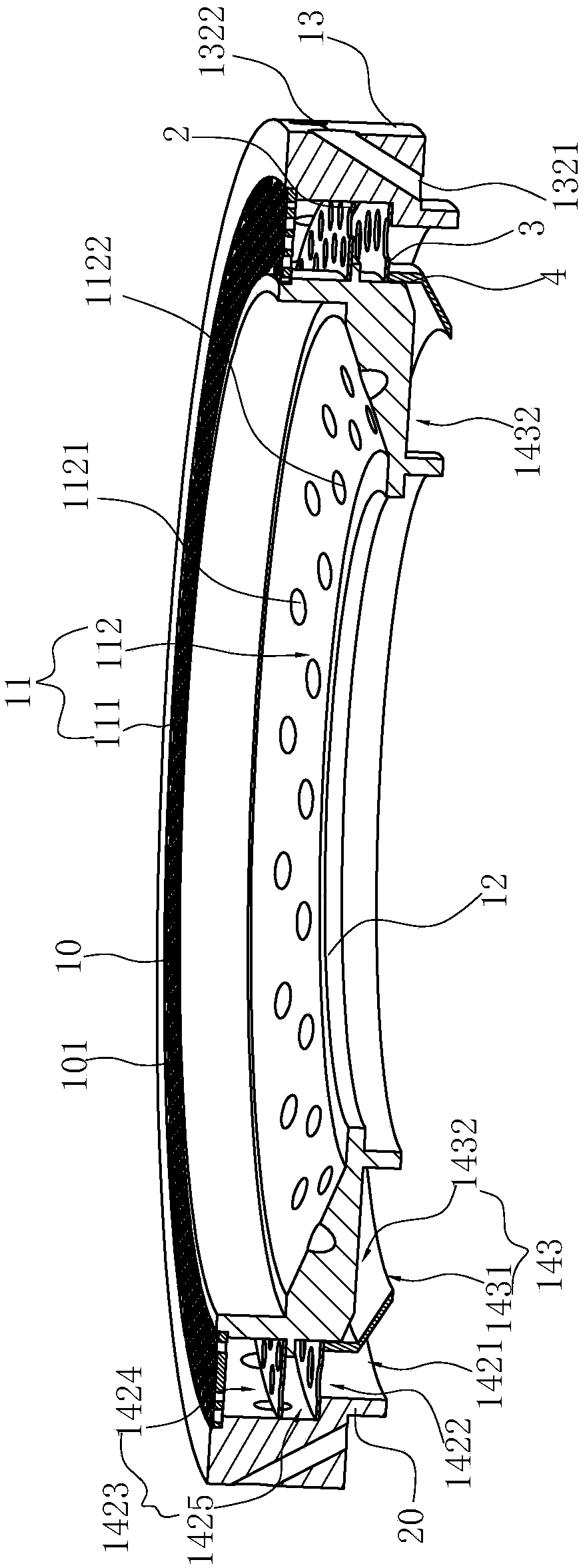

[0034] Such as Figure 1~4 Shown is the preferred embodiment of the present invention. The fire cover for the gas cooker of the present embodiment includes a fire cover, and the fire cover includes a ring-shaped body 1, the ring-shaped top wall 11 of the body 1 and the inner edge and the outer edge of the ring-shaped top wall 11 respectively. A gas mixing chamber 14 is formed between the inner ring wall 12 and the outer ring wall 13 extending downward; wherein, the outer ring wall 13 has at least two main fire holes 131 arranged at intervals along the circumferential direction, and the outer ring wall 13 is located at the main fire holes 131 There are at least two flame stabilizing holes 132 arranged at intervals along the circumferential direction below the bottom of the flame stabilizing hole. Below the hole 131, a first flow divider is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com