Skid-mounted oil well ten-closure one-separation recycling device

A separation and recovery, skid-mounted technology, used in wellbore/well components, production fluids, earth-moving drilling, etc. Clear steps and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

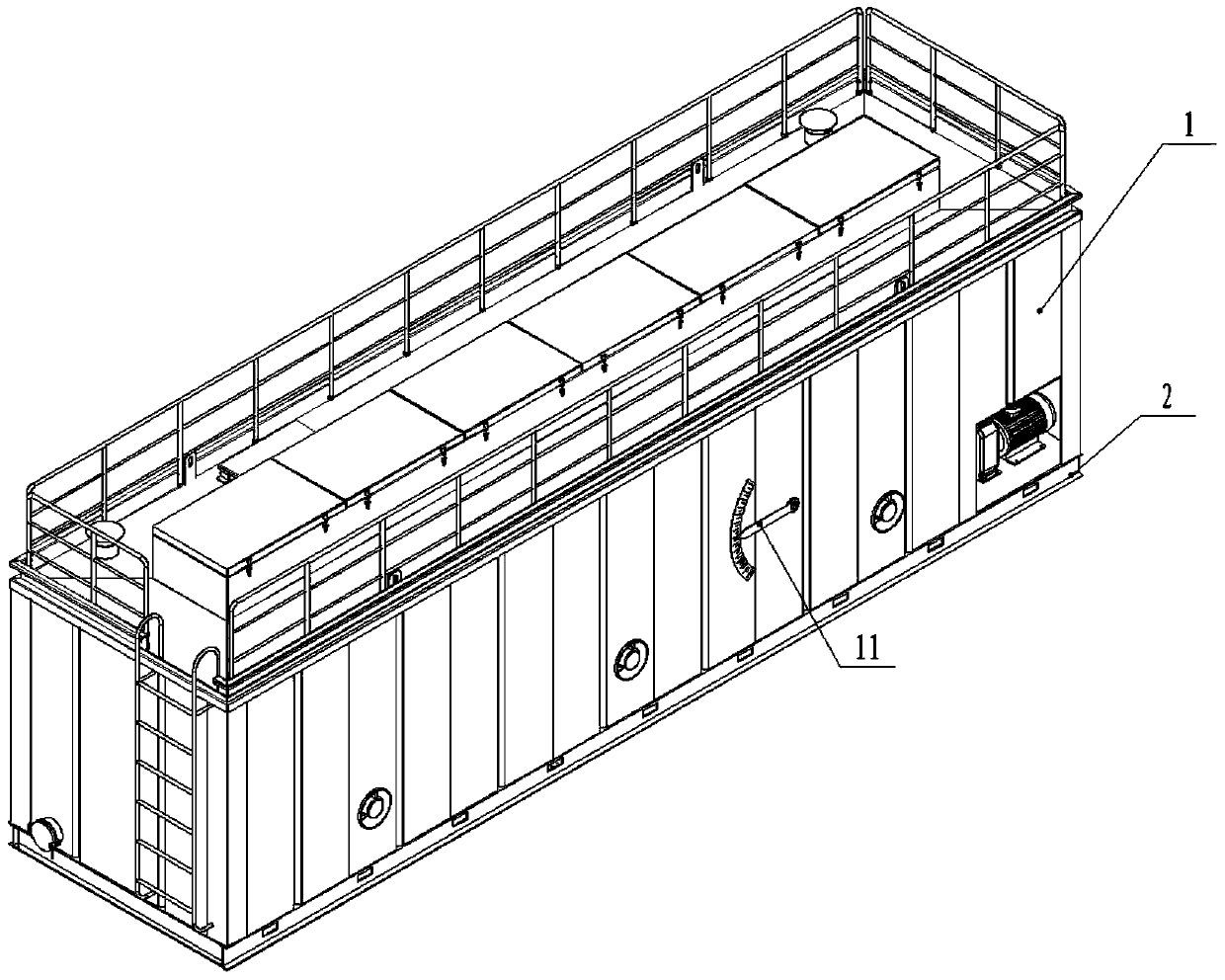

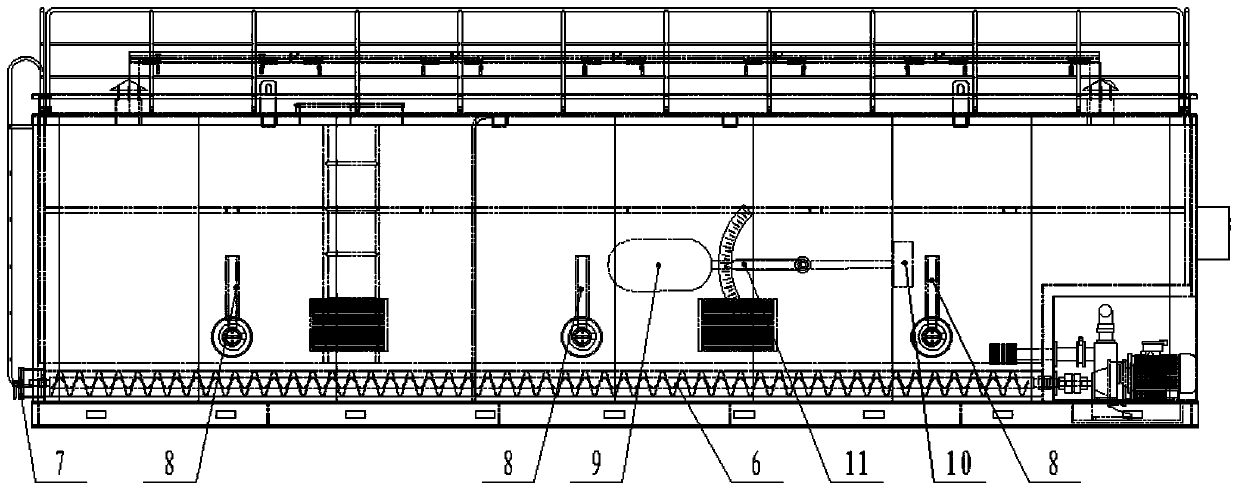

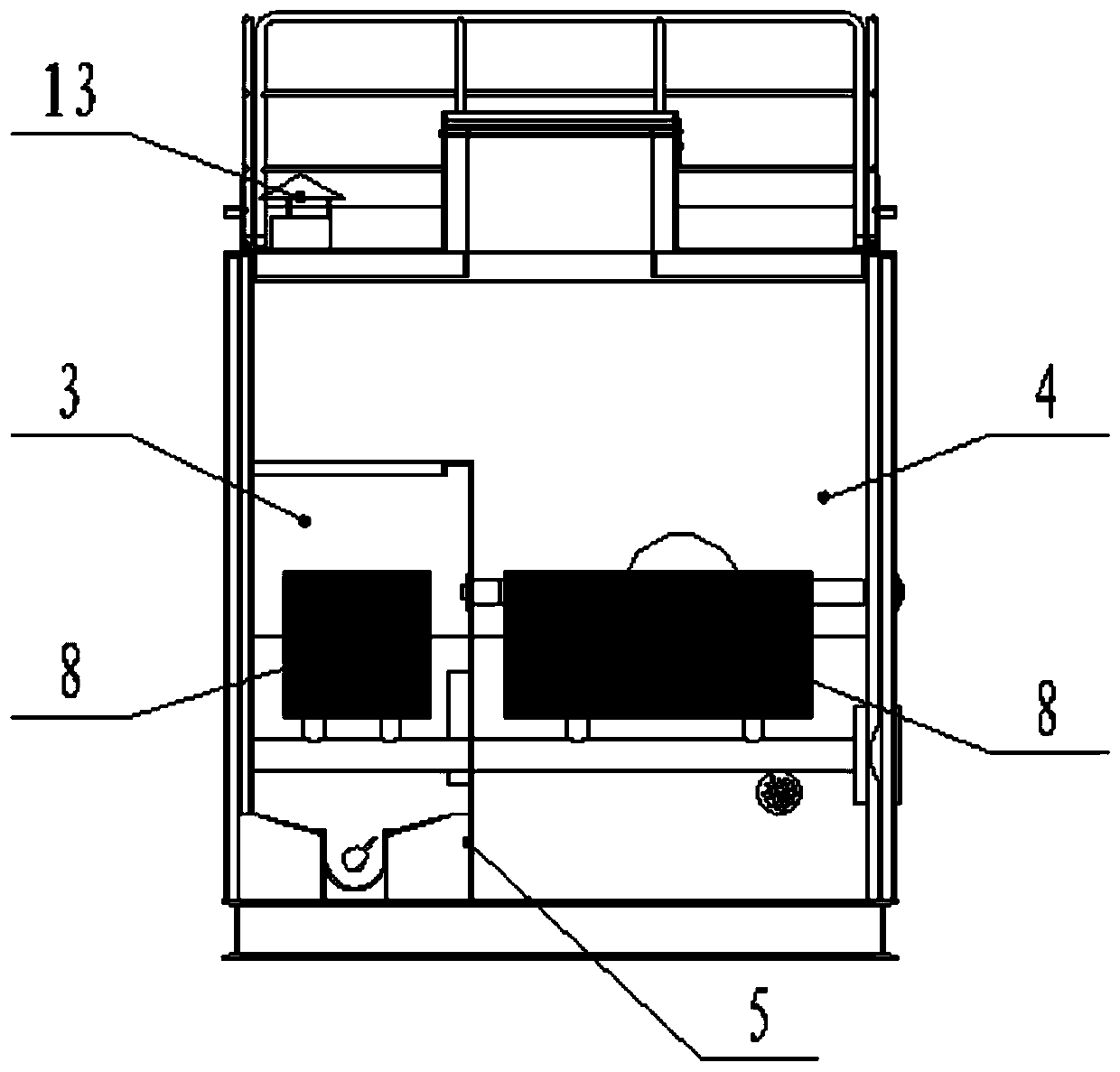

[0014] This embodiment includes a tank body 1 with a rectangular parallelepiped structure, the tank body 1 is fixedly installed on the chassis 2, and the tank body 1 is moved by prying the chassis 2 to make it movable and convenient for transfer and use between wellheads . The inside of the tank 1 is divided into two chambers in the width direction, which are respectively called the blowout buffer settlement separation chamber 3 and the crude oil recovery chamber 4. The two chambers are separated by a separation plate 5, and the blowout buffer settlement The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com