Material taking device and method based on visual following

A reclaiming device and visual technology, applied in conveyor control device, transportation and packaging, conveyor objects, etc., can solve problems such as untimely grabbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

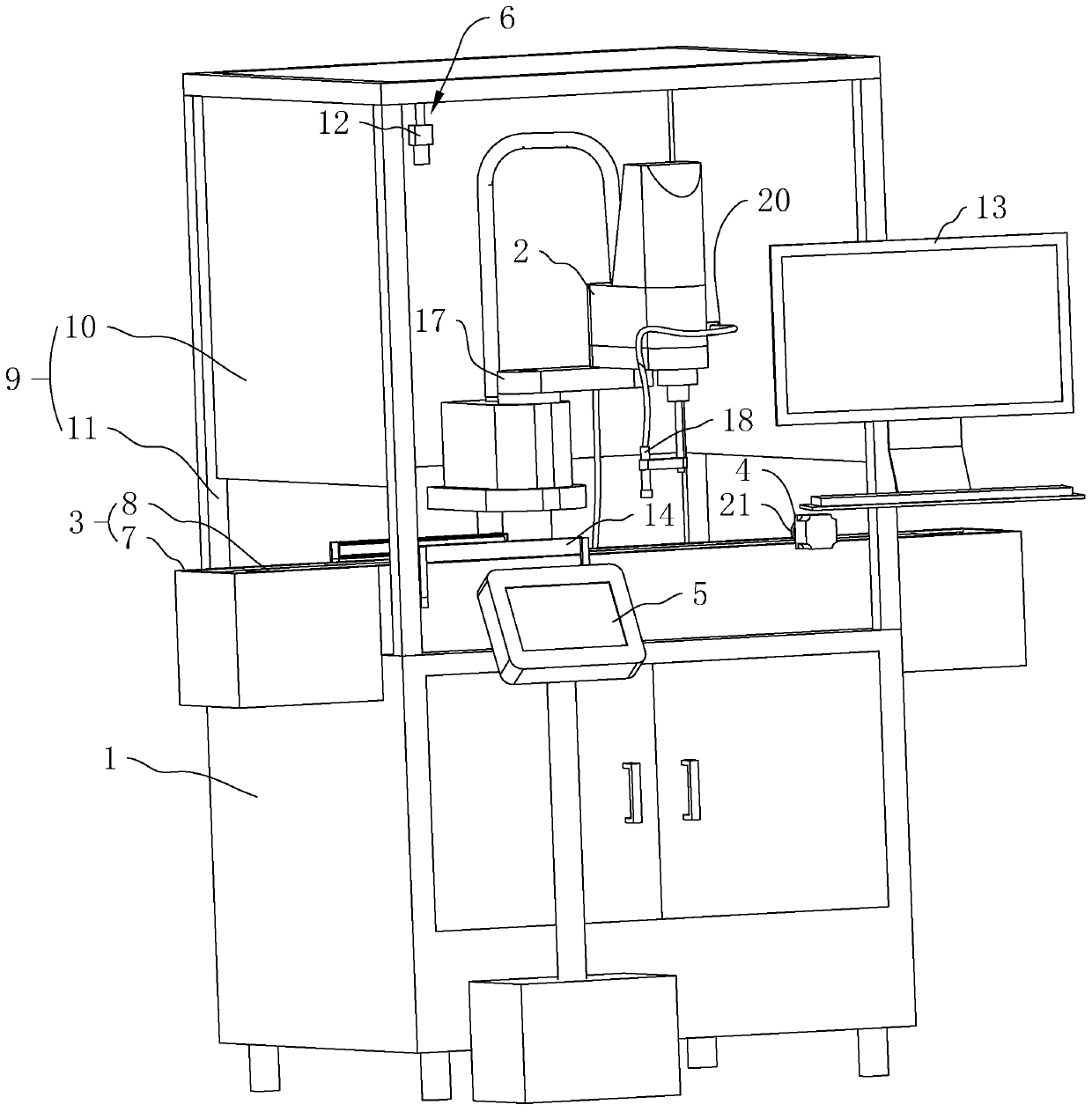

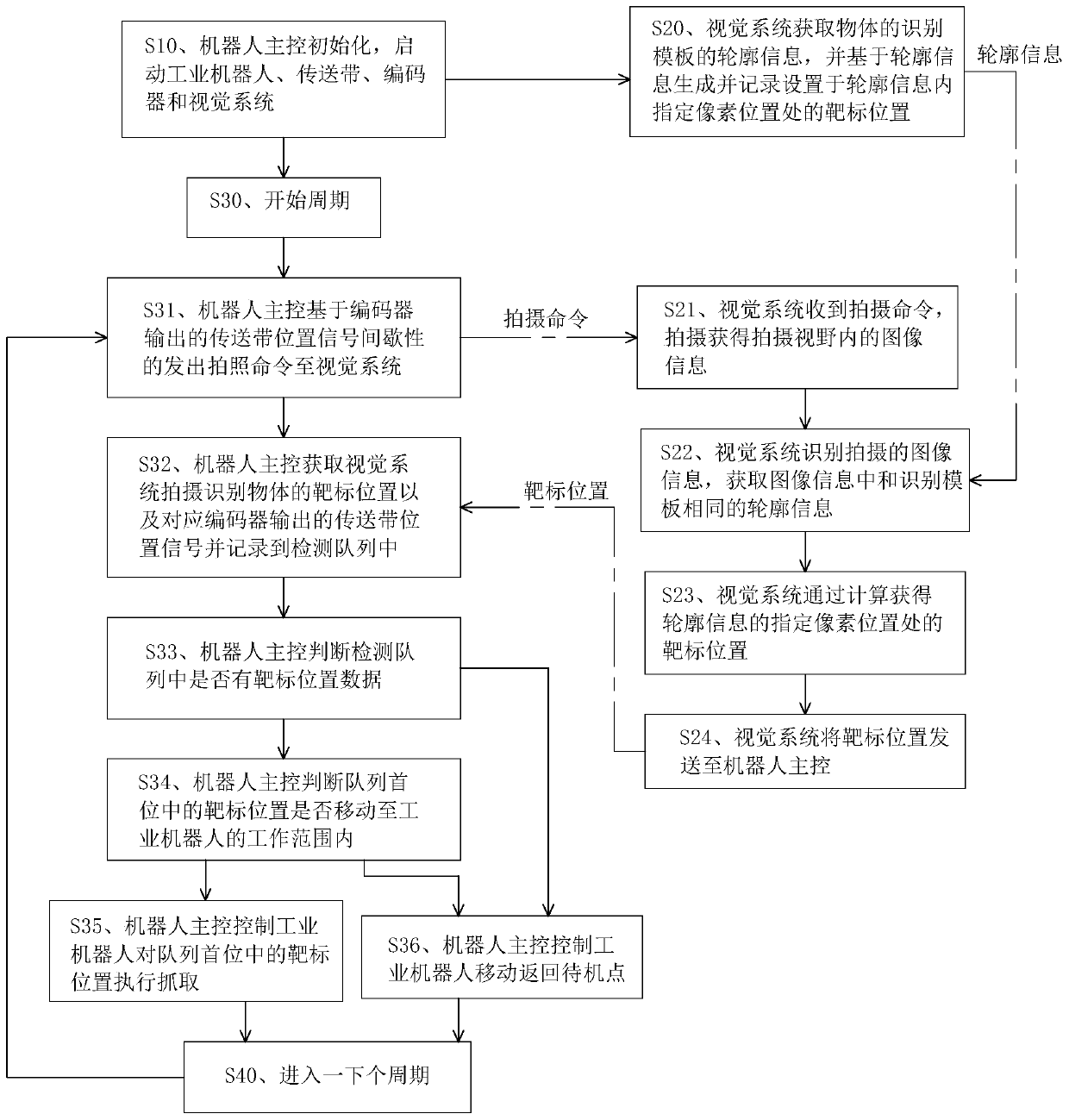

[0078] Embodiment, a kind of reclaiming device based on vision following, such as figure 1 As shown, it includes a workbench 1 , a vision system 6 , an industrial robot 2 , a conveyor belt 3 , an encoder 4 and a robot master control 5 . The top surface of the workbench 1 is set as a horizontal tabletop; the conveyor belt 3 is horizontally installed on the tabletop for conveying objects; the visual system 6 is installed on the workbench 1, and its shooting field of view is facing the front side of the conveying direction of the conveyor belt 3; The industrial robot 2 is installed on the workbench 1 and is adjacent to the rear side of the conveying direction of the conveyor belt 3, and has a working range for grabbing the rear side of the conveying direction of the conveyor belt 3. The field of view of System 6 is staggered. The output shaft of the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com