Method and device for reducing wave-making resistance and friction force during ship navigation

A technology of wave resistance and friction, applied in the field of water navigation, can solve problems such as limited bulbous bow performance, achieve the effects of reducing wave resistance, improving maneuverability, and increasing air content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

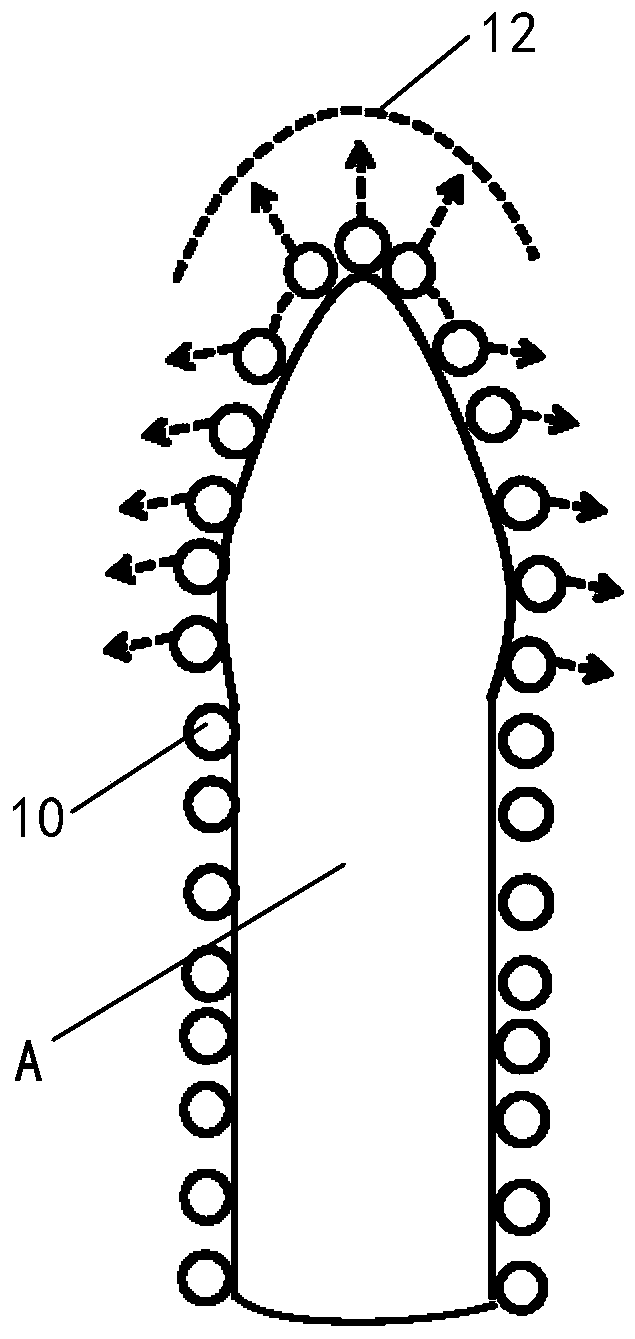

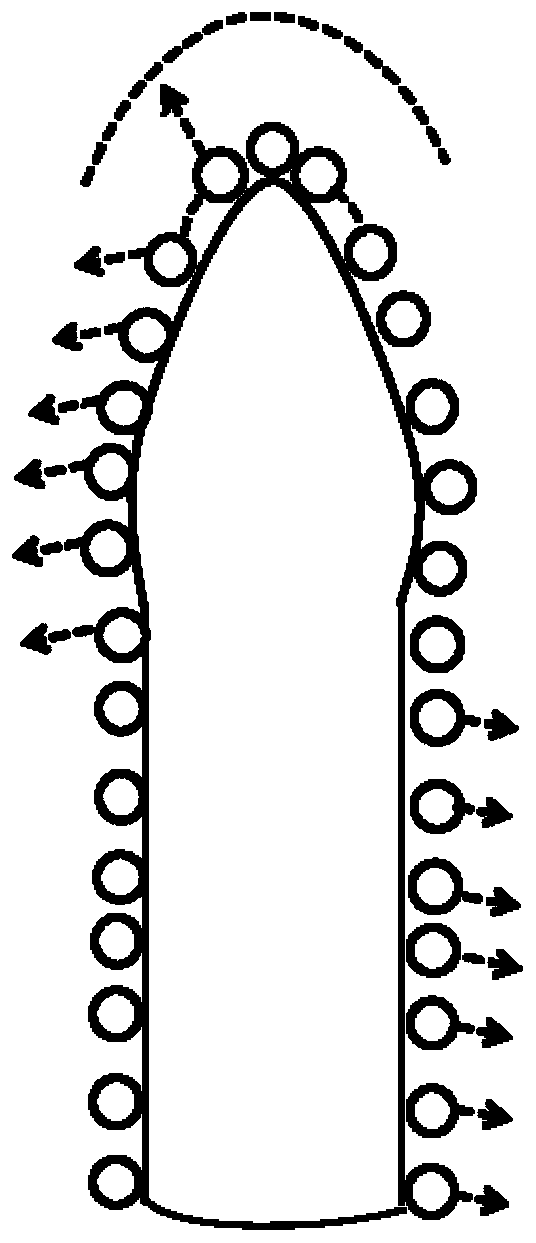

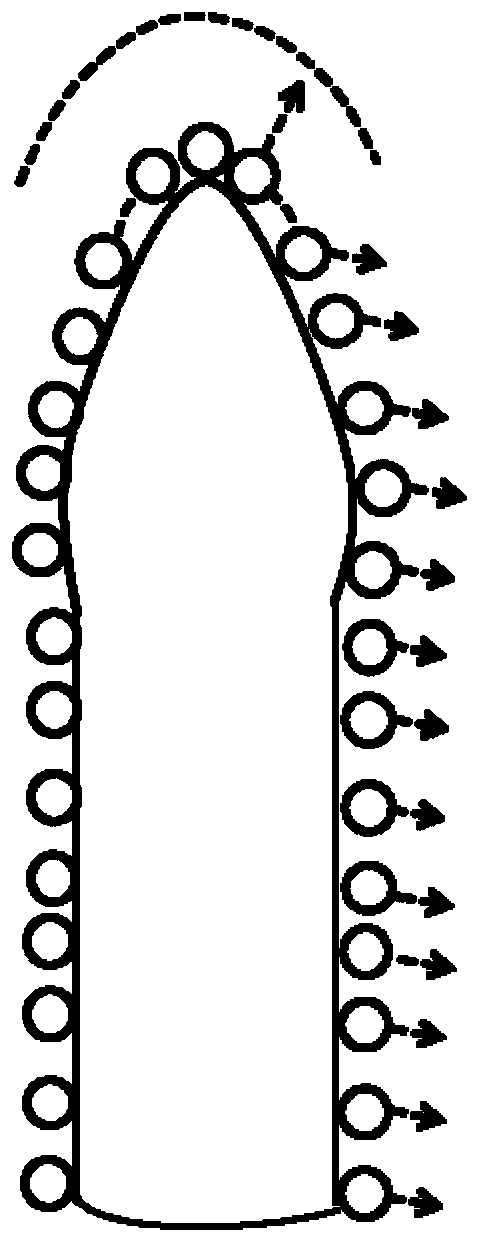

[0054] Such as figure 1 , 2 , 3, the method of the present invention to reduce wave resistance and friction when the ship is sailing is to inject a gas-water mixture containing bubbles to the front end of the ship A or / and the waters on both sides of the ship (the arrow in the figure indicates the direction of injection) .

[0055] In the air-water mixture, the air accounts for 10%-60% by volume, preferably, the air accounts for 40%.

[0056] Preferably, when injecting the mixture of air and water containing air bubbles into the waters on both sides of the ship, try to only inject the air-water mixture containing air bubbles into the waters in the front of the hull, that is to say, the injection position does not exceed the position of the hull. In the middle, avoid bubbles bursting to damage the propeller and other devices at the stern of the ship. Special ships, such as tugboats, can also inject an air-water mixture into the water at the middle and rear of the hull.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com