Polyurethane foaming module capable of automatically removing excess materials

A foaming mold, polyurethane technology, applied in the field of production and processing, can solve the problems of overflow of residual material, easily affecting the normal production of products, low efficiency of manual cleaning, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

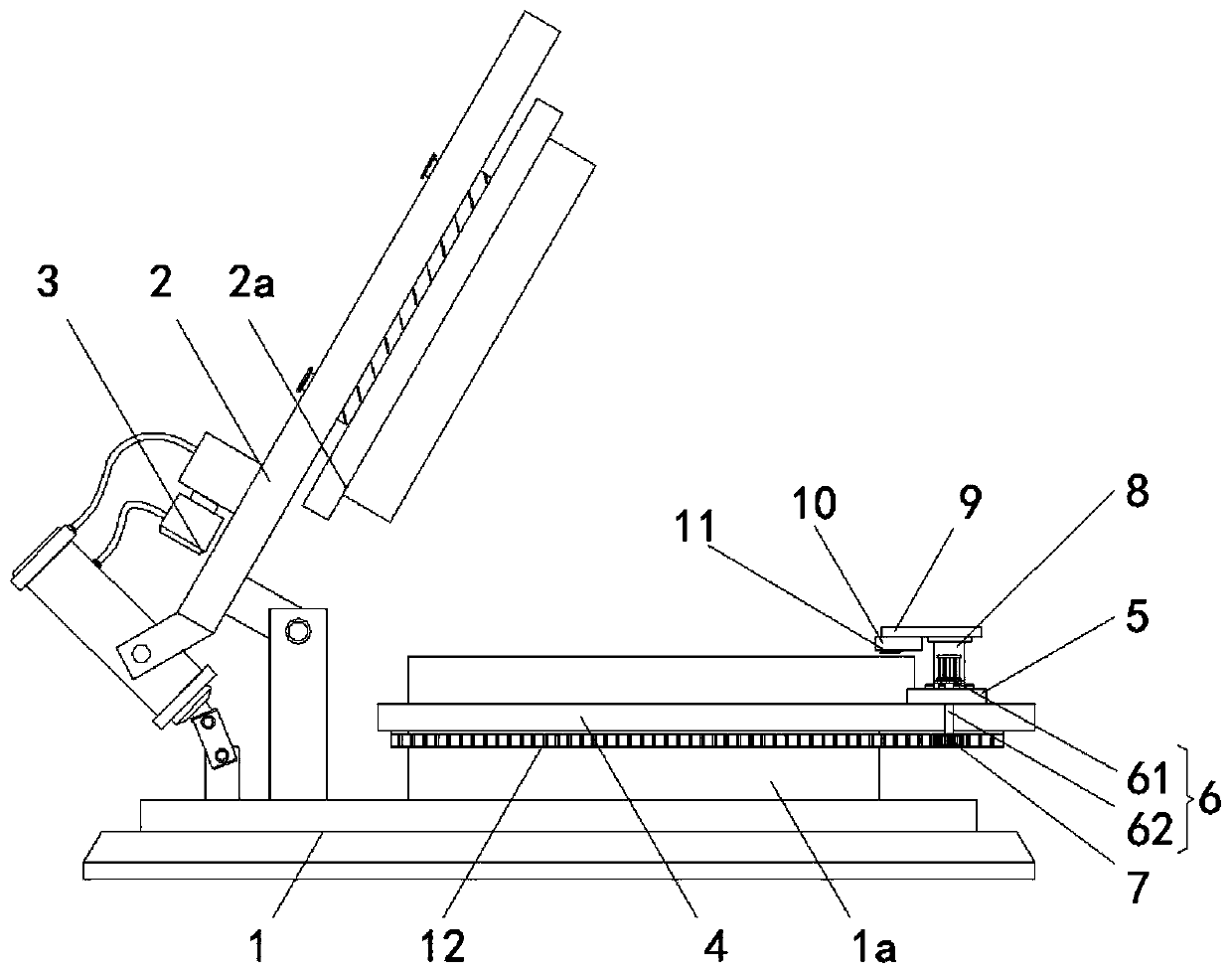

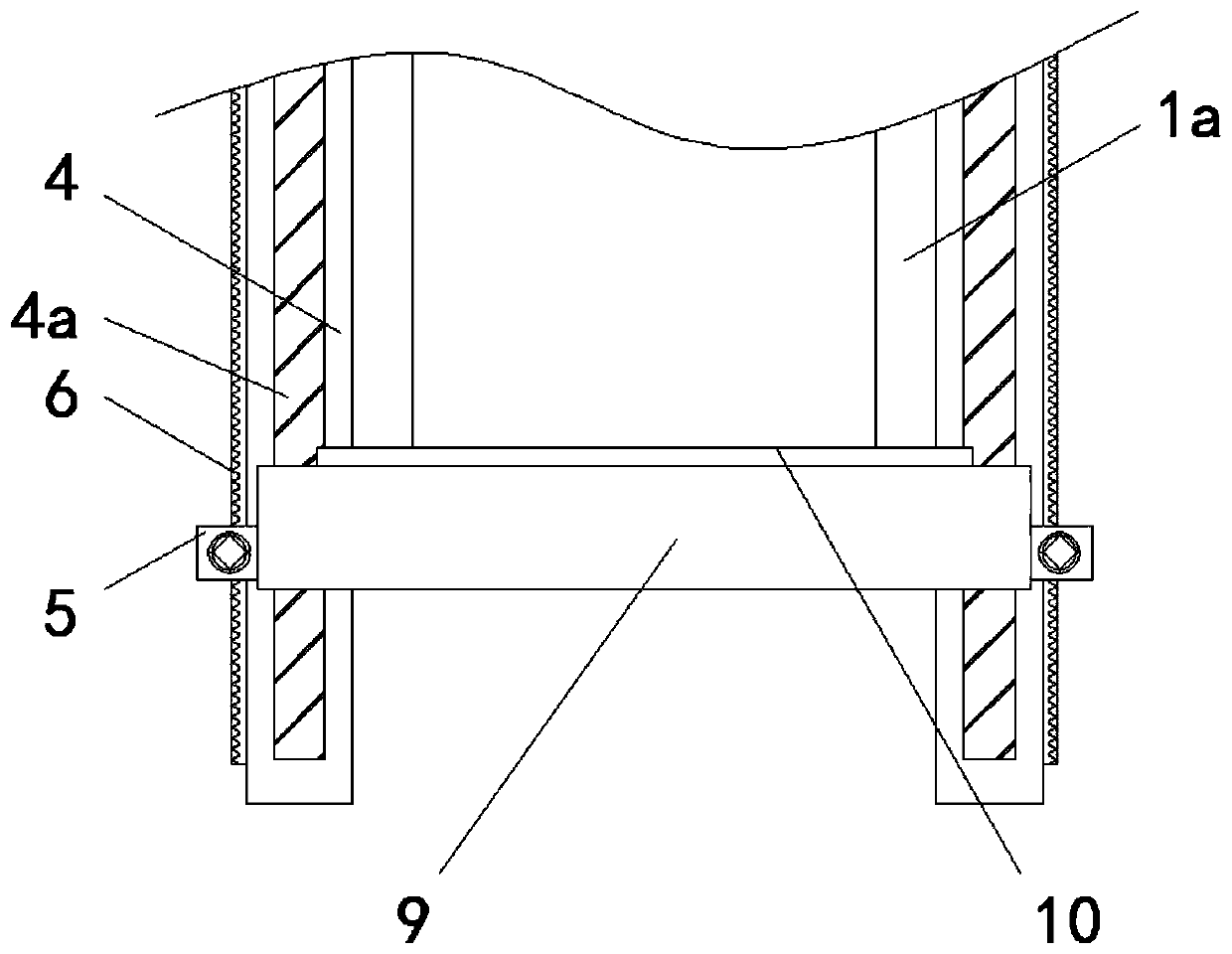

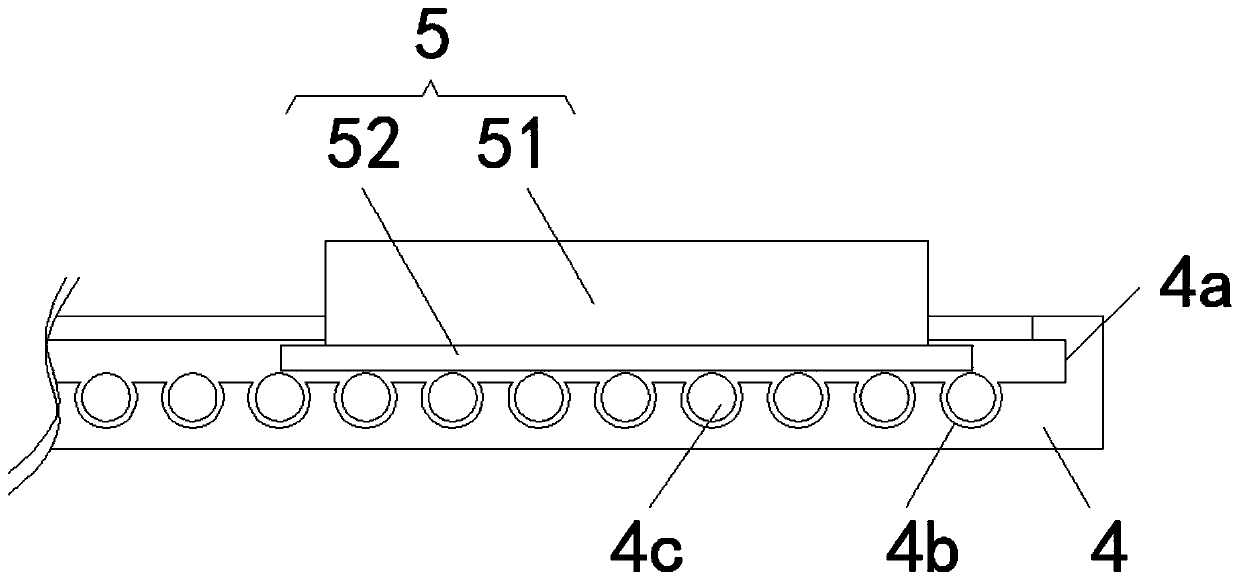

[0026] Such as figure 1 and figure 2 Shown, a kind of polyurethane foaming module that removes surplus material automatically, comprises bottom frame 1, bottom mold 1a erected on bottom frame 1, top frame 2, top mold 2a installed on top frame 2 and used to push The bottom mold 1a and the top mold 2a complete the mold clamping and mold opening propulsion mechanism 3, and also include two guide rails 4 symmetrically arranged outside the bottom mold 1a. The top of the guide rails 4 is movably equipped with a moving part 5, and the bottom is provided with a rack 12. Bottom column 8 is installed on the moving part 5, and driving mechanism 6 is also installed on the moving part 5, and the transmission gear 7 that meshes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com