Semiconductor device test fixture and test box body

A technology for testing fixtures and semiconductors, which is used in the testing of single semiconductor devices, parts and instruments of electrical measuring instruments, etc., can solve the problems of manual tightening of screws, time-consuming and labor-intensive, etc., to achieve convenient and detachable connections, improve work efficiency, and facilitate detection. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

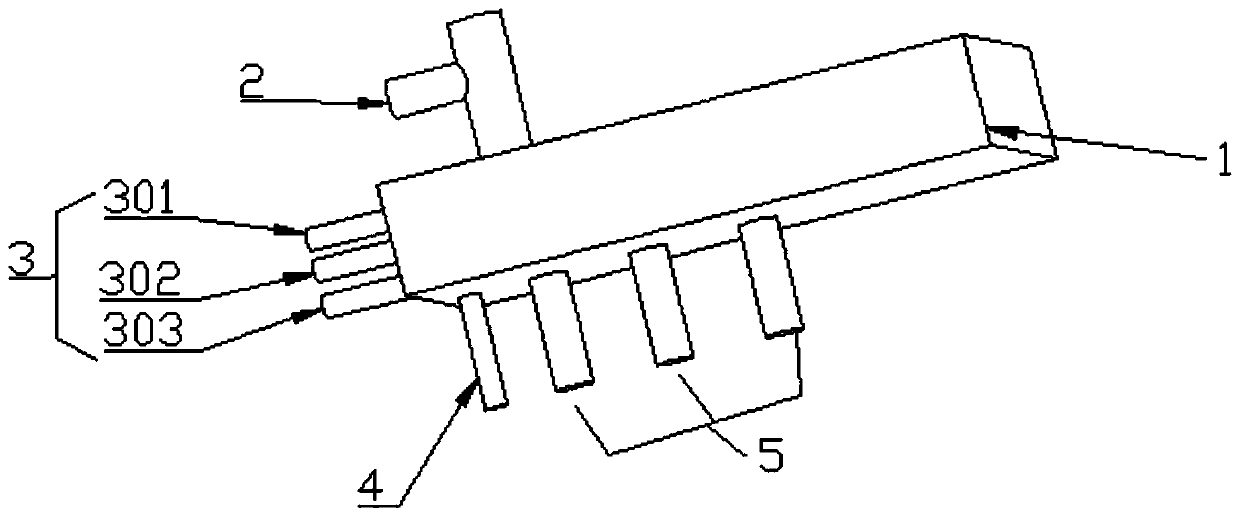

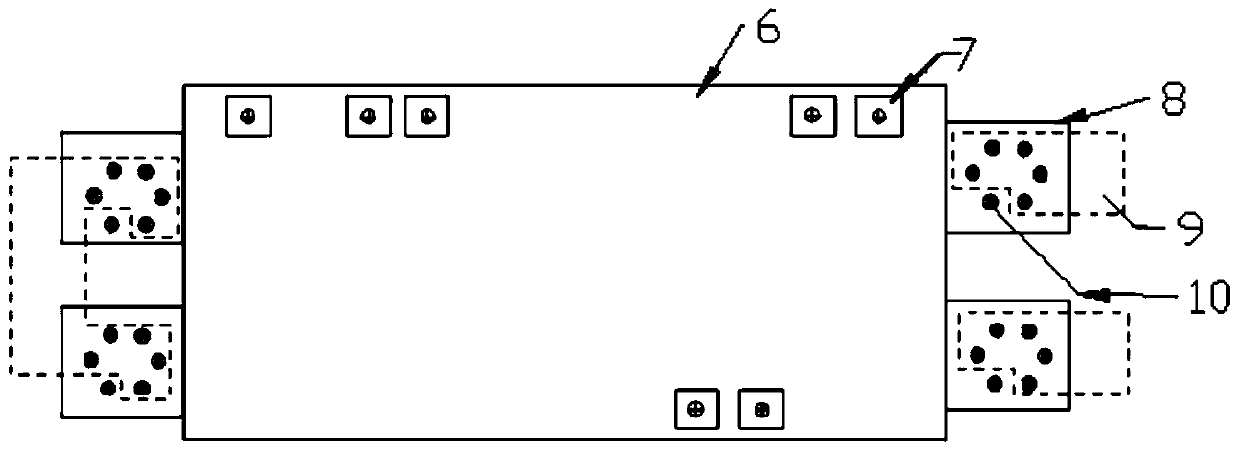

Method used

Image

Examples

Embodiment 2

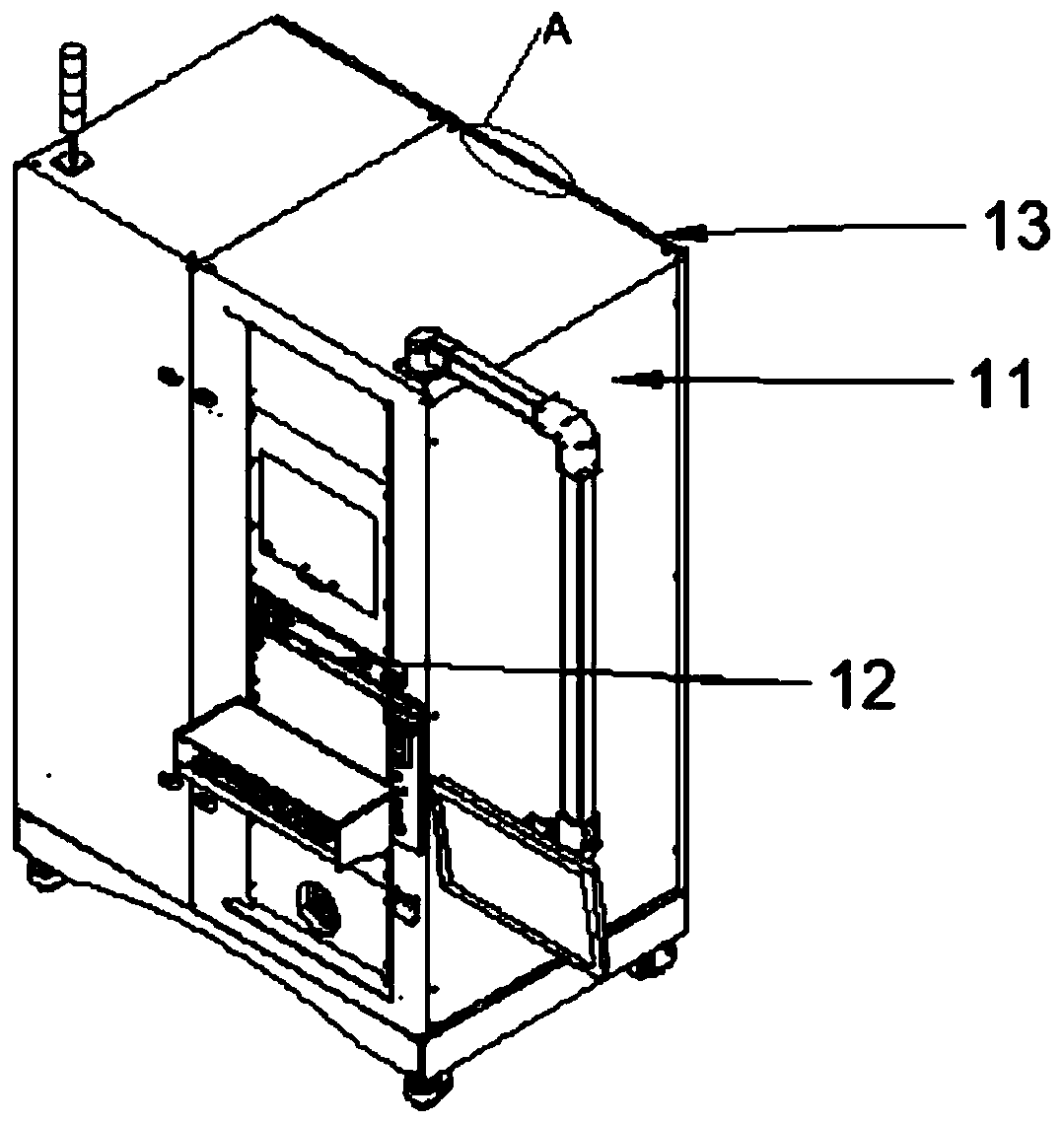

[0037] Such as Figure 3-Figure 4 , image 3 Schematic diagram of the axial side of the semiconductor device test box; Figure 4 for image 3 An enlarged schematic diagram of the rear view of middle A; a semiconductor device test box, including a box body 11, a semiconductor device test automation tool 12, a laminated busbar connection device 13, and a semiconductor device test fixture,

[0038] The box body 11 is provided with a stretchable semiconductor device test automation tool 12 inside the lower right side of the front side, and the rear side wall of the box body 11 is provided with a laminated busbar connection device 13, and the laminated mother The row connecting device 13 is connected to the semiconductor device test fixture through a probe, the semiconductor device test fixture is connected to the DUT 6 through a probe, the semiconductor device test fixture is set on the top of the semiconductor device test automation tool 12, and The semiconductor device test fixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com