Drying device for oxygen breathing apparatus

A drying device and respirator technology, applied in drying, drying machine, drying gas arrangement and other directions, can solve the problems of inability to meet rescue, complexity, multiple structures of pipelines and cavities, and achieve flexible and changeable use methods. , the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

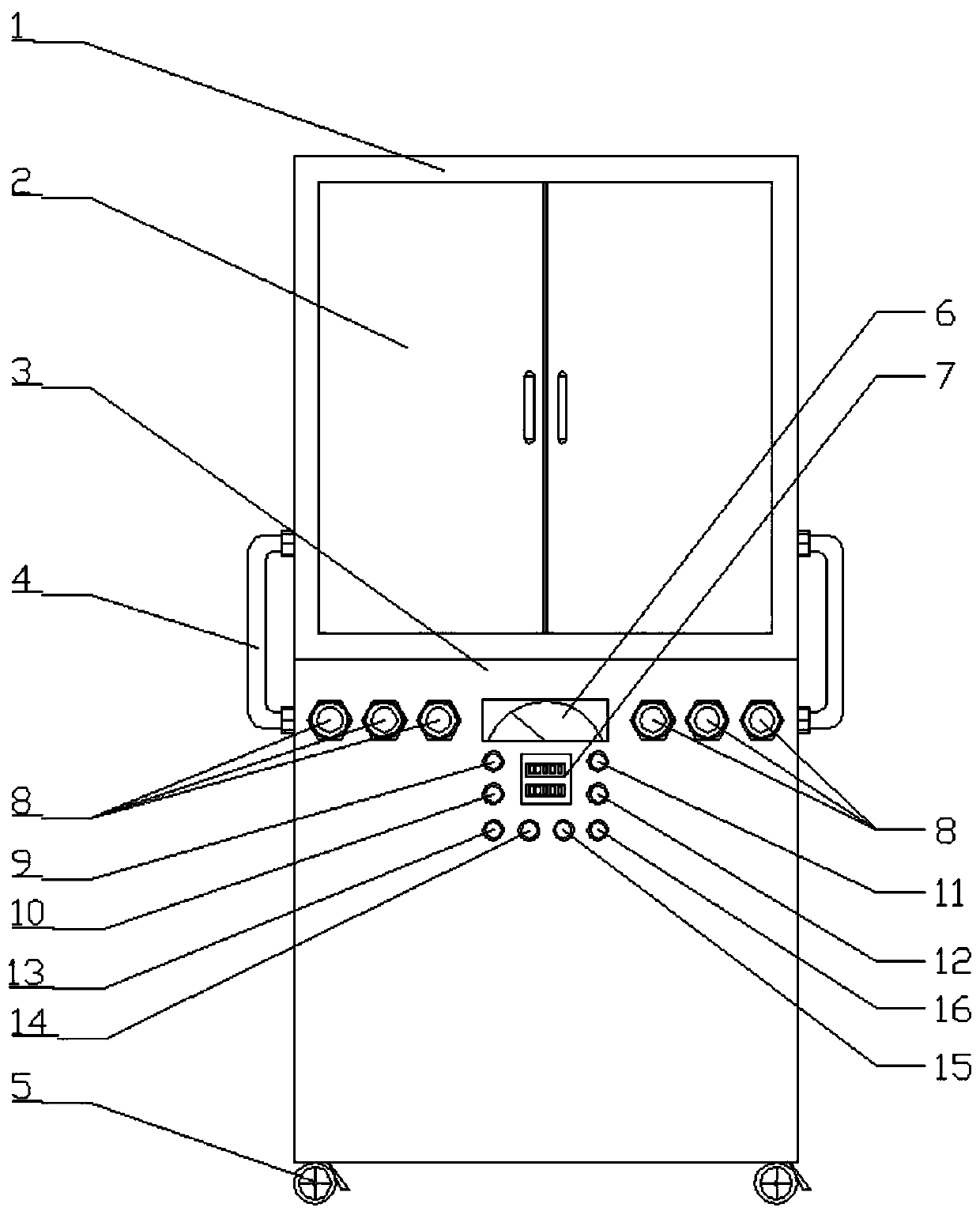

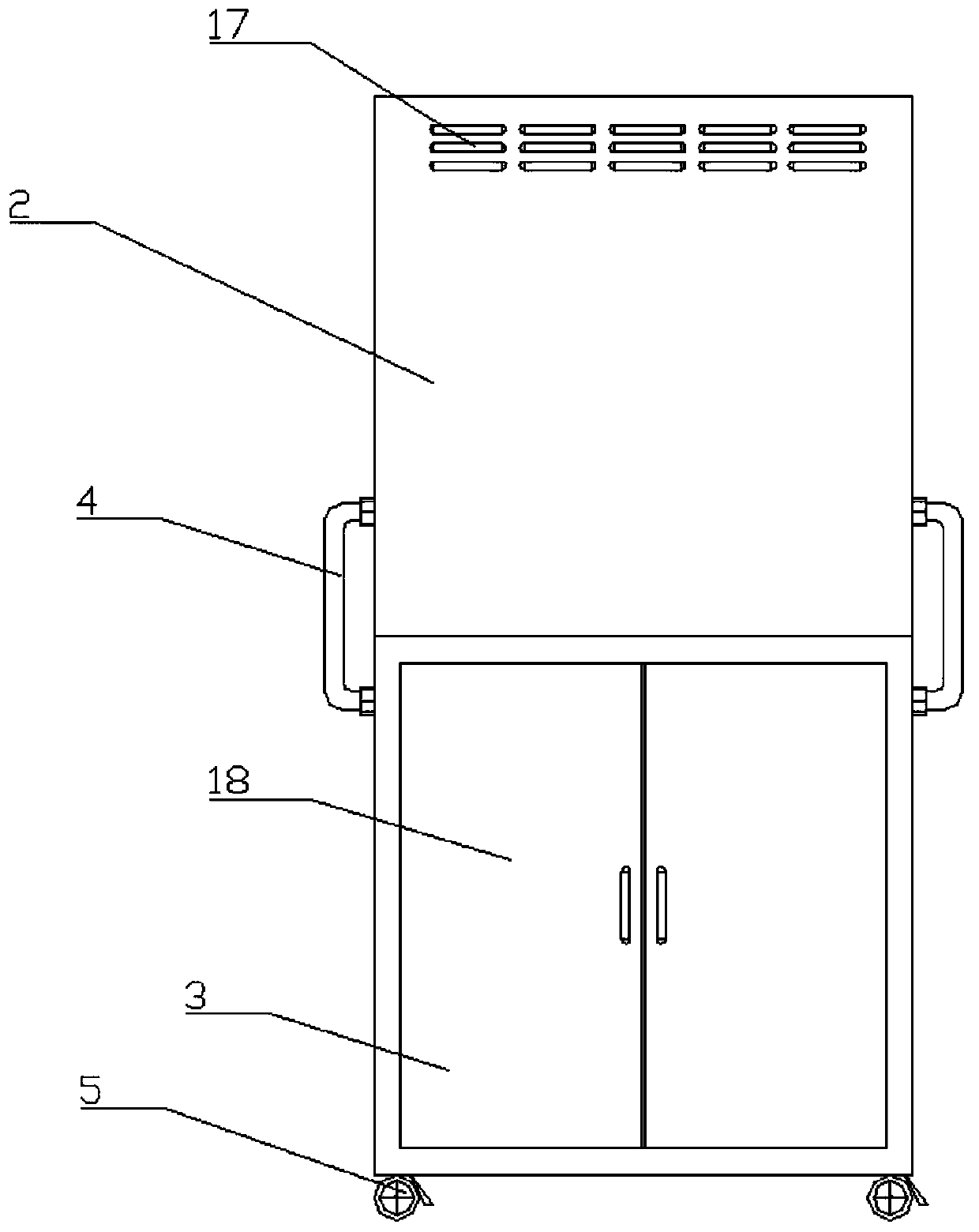

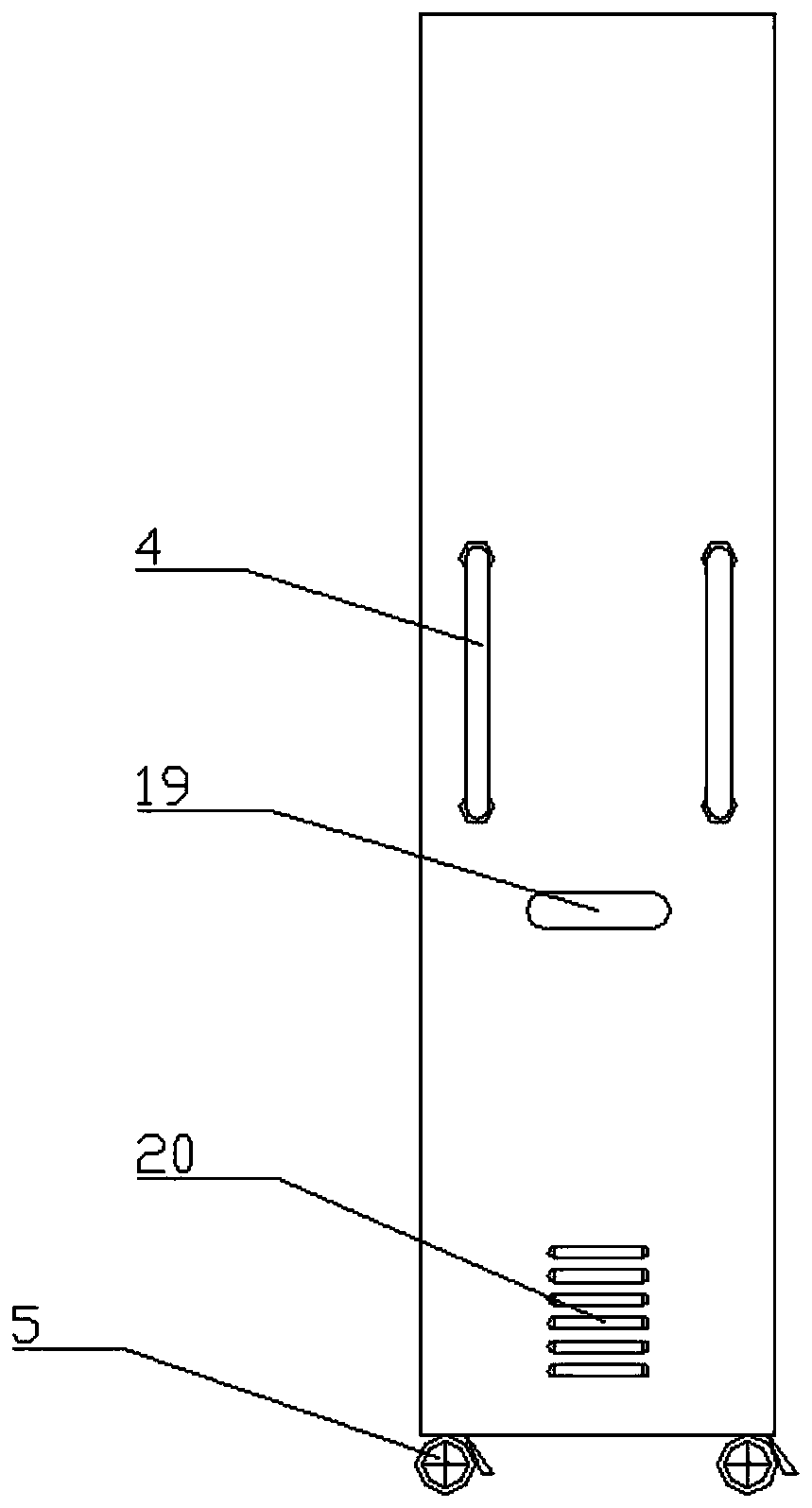

[0018] Such as Figure 1 to Figure 3 As shown, the drying device for oxygen breathing apparatus in this embodiment includes a parts drying chamber 2, a complete machine drying cabinet 3, several side air ducts 4, four universal wheels 5, several Hot air interface 8, top cooling holes 17, drying box door 18, bottom cooling holes 20 and a drying control device, the drying control device includes a temperature controller 6, a timer 7, a power switch 9, a fan 21 and a hot air box 22, wherein: the parts drying chamber 2 is set on the top of the complete machine drying cabinet 3, the parts drying chamber 2 is detachably connected to the complete machine drying cabinet 3, and each side air duct 4 is connected to the parts drying chamber 2 The inner cavity of the whole machine drying cabinet 3 and the inner cavity of the complete machine drying cabinet 3, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com