Pump body assembly and slide vane compressor with same

A pump body and component technology, applied in the field of compressors, can solve the problems affecting the operation performance of pump body components and large suction resistance, so as to improve the operation performance and reduce the initial suction resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

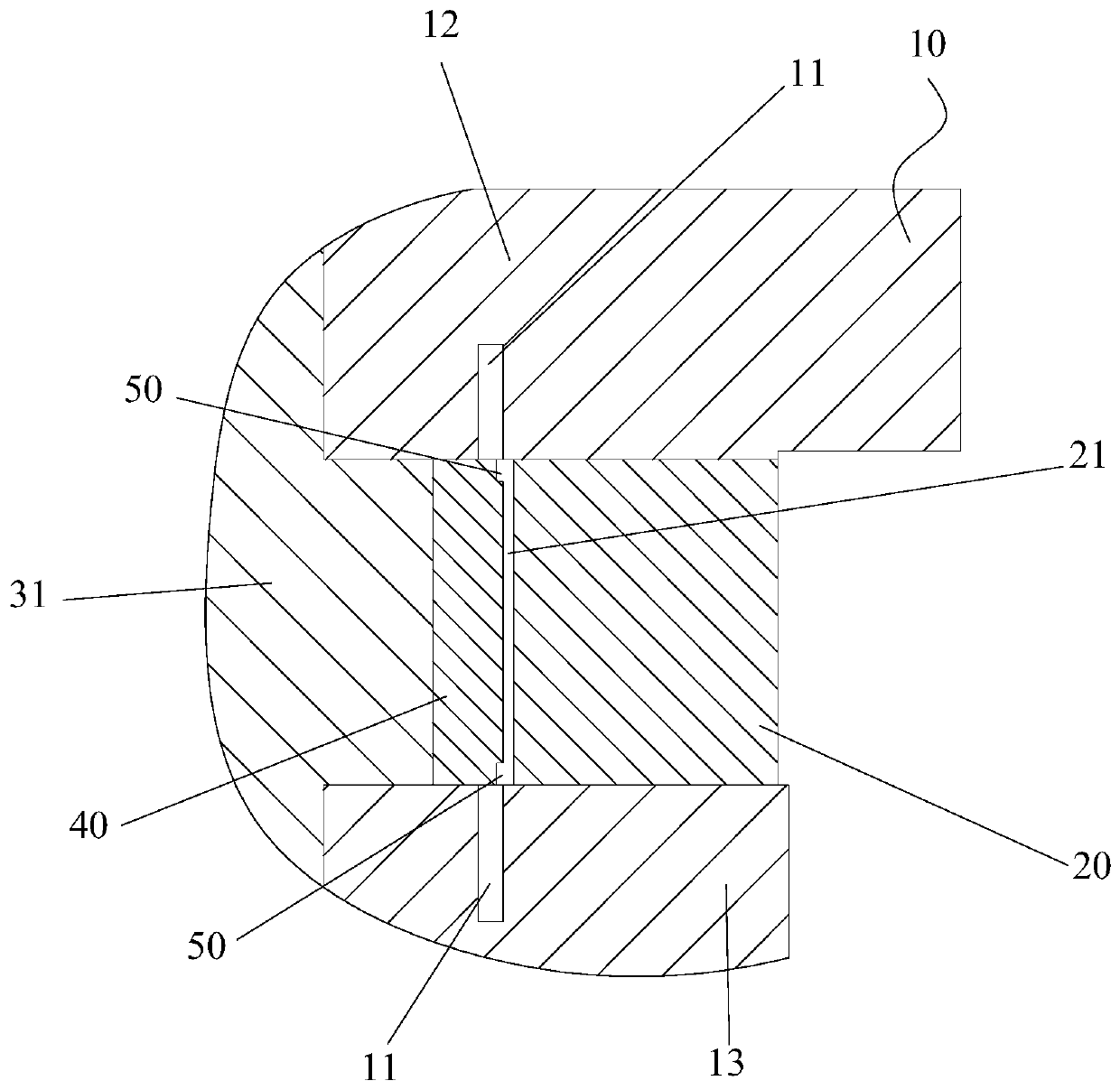

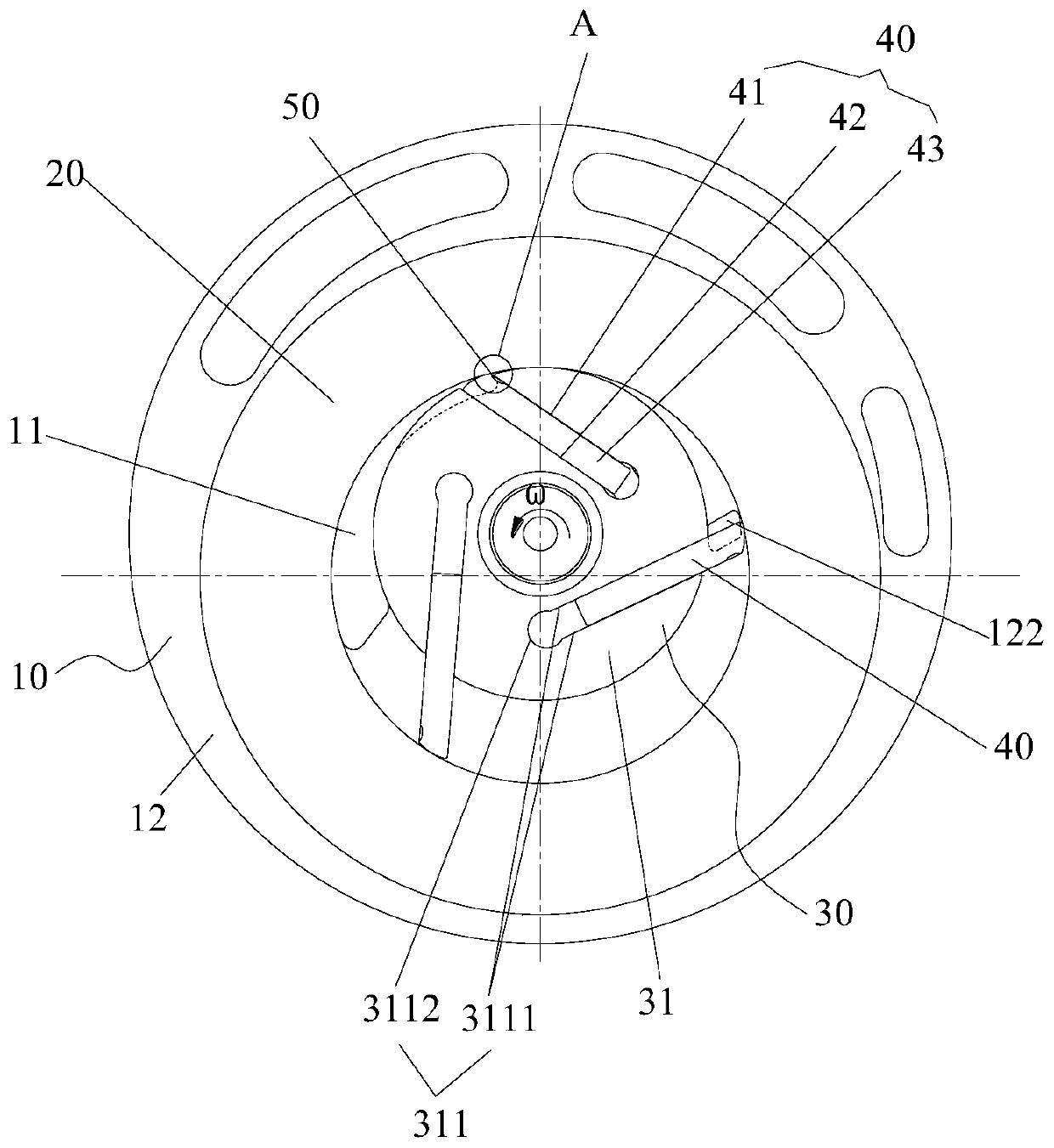

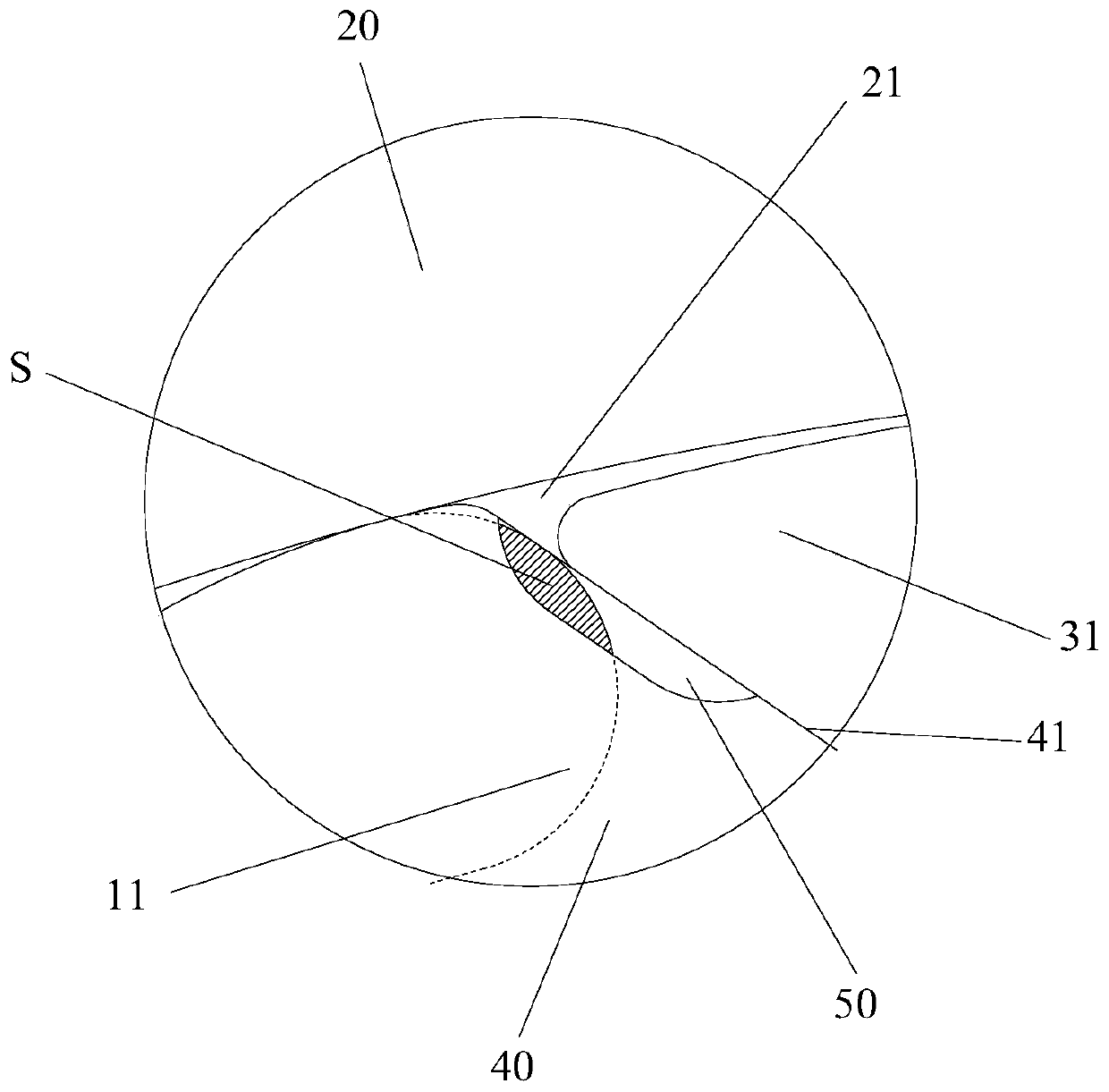

[0038] Such as Figure 1 to Figure 7 As shown, the pump body assembly includes a flange 10, a cylinder 20, a rotating shaft 30 and a plurality of sliding vanes 40, the rotor part 31 of the rotating shaft 30 has a sliding vane groove 311, and the sliding vanes 40 are slidably arranged in the sliding vane groove 311, and the rotor The part 31 is located in the cylinder 20. The slide groove 311 includes two groove walls 3111 and a groove bottom 3112 arranged parallel to each other. The two groove walls 3111 are connected by the groove bottom 3112. The slide plate 40 includes a first surface 41 and a second surface 42 . The first surface 41 and the groove wall 3111 are parallel to each other. The second surface 42 is parallel to the first surface 41 , and the first surface 41 is located behind the second surface 42 along the rotation direction of the rotating shaft 30 . The flange 10 has an air inlet 11 , and the pump body assembly also includes an air inlet 50 . The intake por...

Embodiment 2

[0054] The difference between the pump body assembly in the second embodiment and the first embodiment lies in that the shape of the gap is different.

[0055] Such as Figure 10 As shown, the cross-section of the notch is quadrilateral. In this way, the above arrangement makes the processing of the air intake portion 50 easier and simpler, and reduces the difficulty and cost of processing.

[0056] Such as Figure 10 As shown, the notch includes a fifth surface 51 and a sixth surface 52 connected to the fifth surface 51 , the sixth surface 52 includes three planes connected in sequence, and the three planes surround to form a U-shaped structure. In this way, the above-mentioned structure is simple in structure, easy to process and realize, further reduces the processing cost and difficulty of the notch, and reduces the labor intensity of the staff.

[0057] From the above description, it can be seen that the above-mentioned embodiments of the present invention have achieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com