Tray posture identifying system for AGV forklift and method thereof

A technology of recognition system and recognition method, which is applied in the field of pallet attitude recognition system, can solve the problems of large influence, high price of multi-line laser radar, low cost of single-line laser radar, etc., and achieve good fork lift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

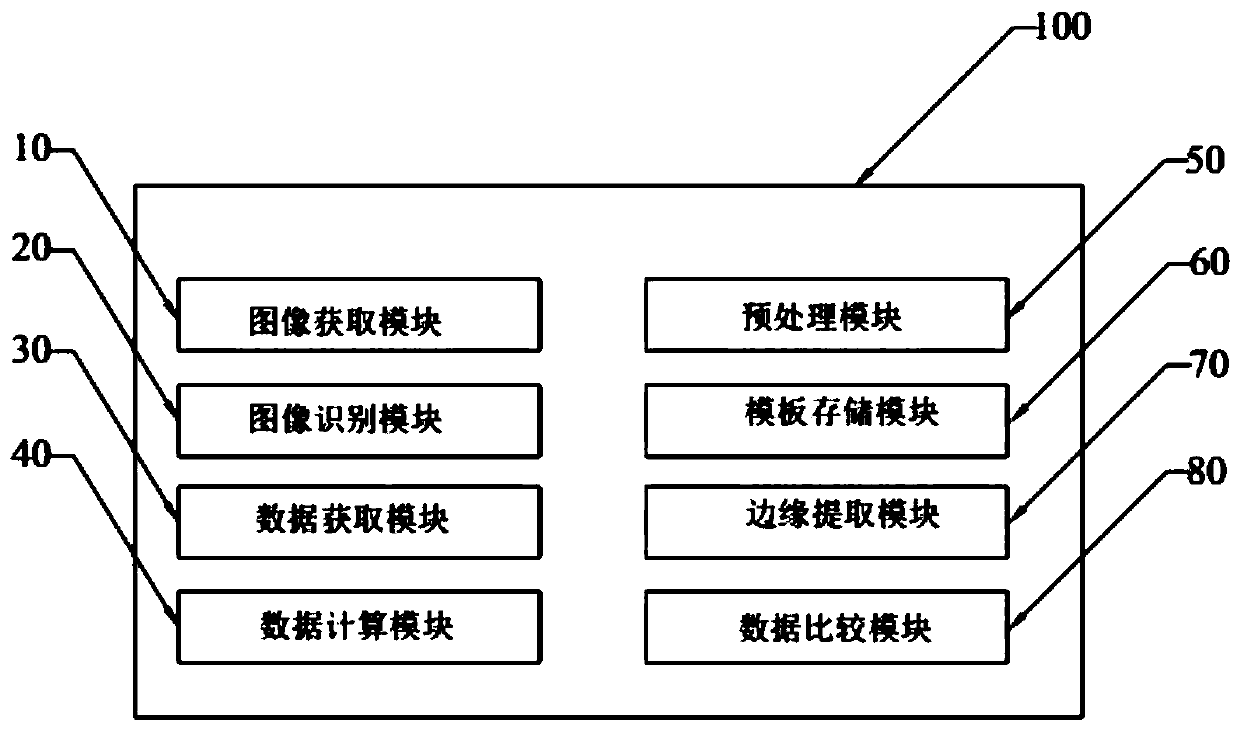

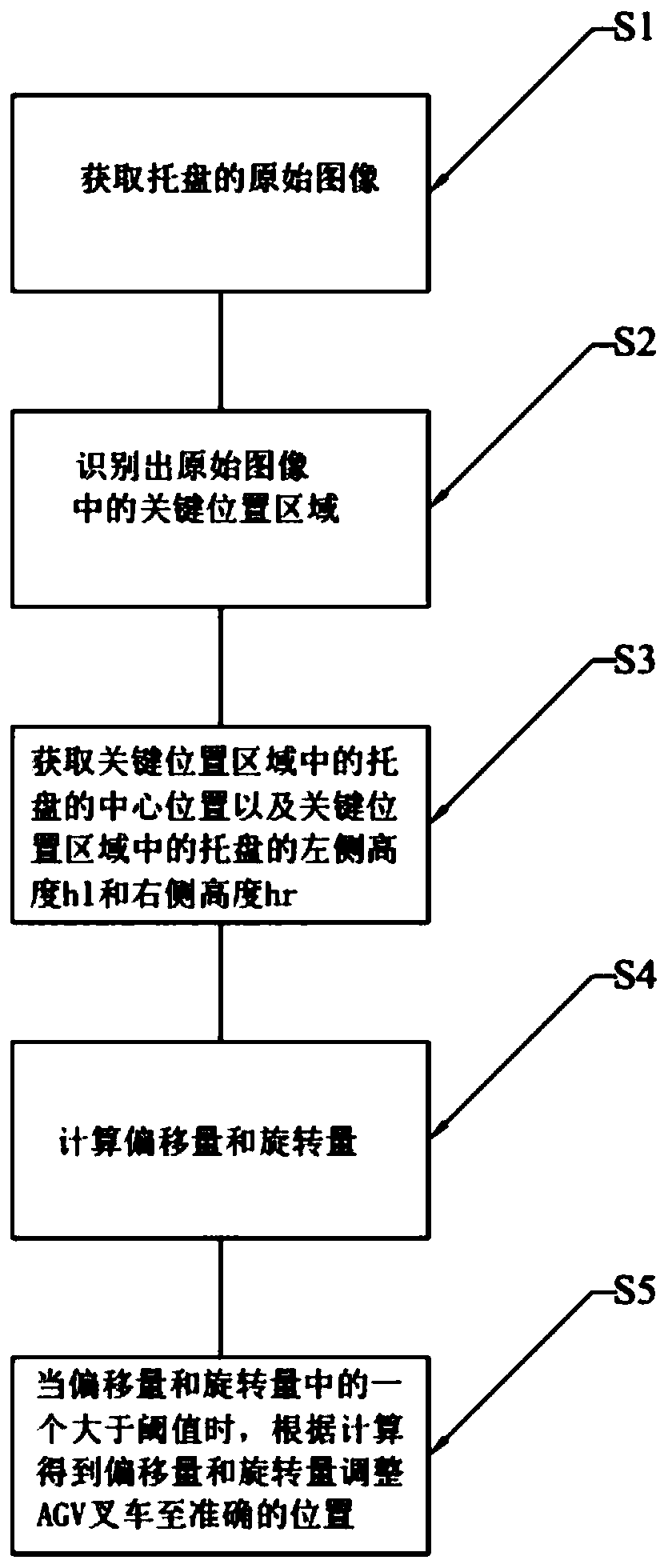

[0036] Such as figure 1 Shown is a pallet attitude recognition system 100 for an AGV forklift, including: an image acquisition module 10 , an image recognition module 20 , a data acquisition module 30 and a data calculation module 40 . Wherein, the image acquisition module 10 is used to acquire the original image of the pallet. The image recognition module 20 is used to receive the original image acquired by the image acquisition module 10 and identify the key position area from the original image. The data acquisition module 30 is used to acquire the center position of the pallet in the key position area and the left height hl and right height hr of the pallet in the key position area. The data calculation module 40 is used to calculate the distance between the center position of the tray in the original image and the center position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com