Tea leaf fixation processing technology and equipment therefor

A processing technology and tea technology, applied in the field of tea processing and production equipment, can solve the problems of difficulty in ensuring the quality stability of tea greening, unguaranteed tea quality, affecting tea drinking and viewing, etc., and achieves good practicability and simple structure. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

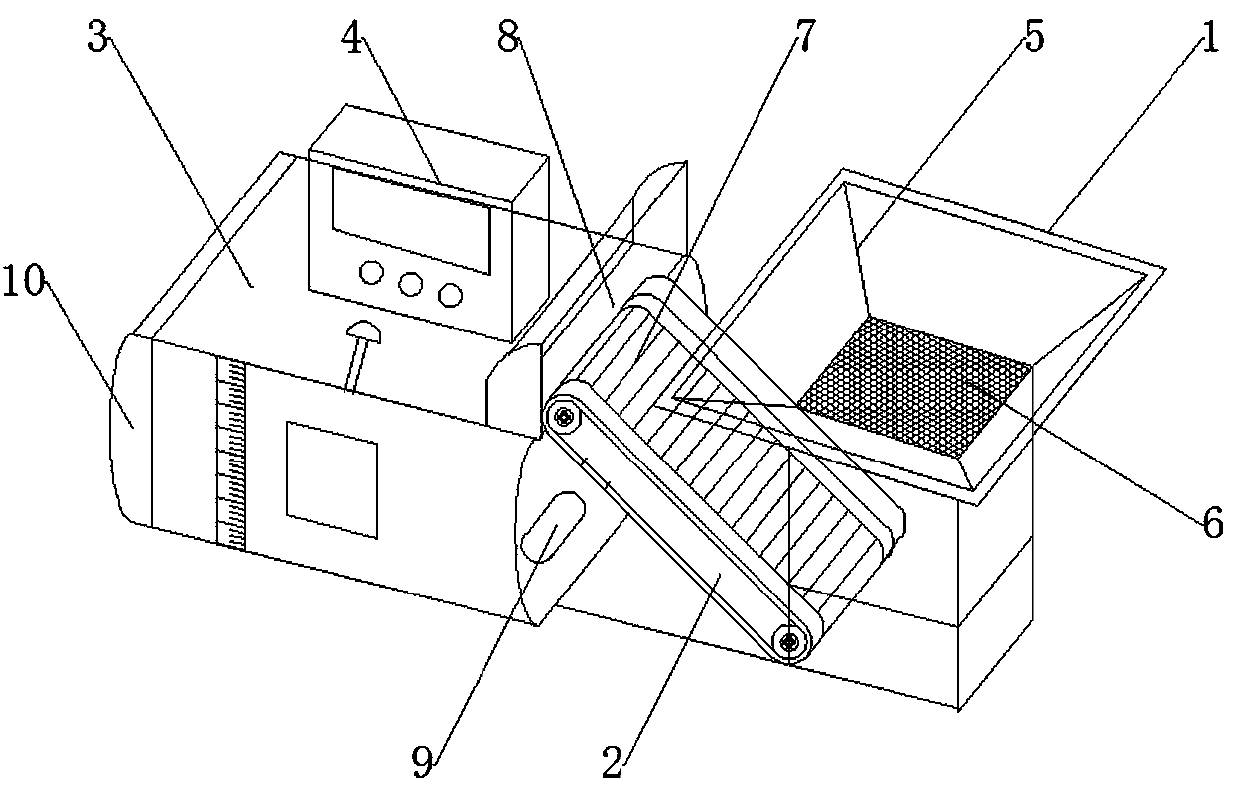

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0024] A kind of processing technology of tea leaves greening, specifically comprises the following steps:

[0025] S1, adding the tea leaves to be processed to the conveying mechanism;

[0026] In S1, the fresh tea leaves to be processed are regularly and quantitatively added to the input end of the conveying mechanism by the quantitative mechanism, and the amount of tea leaves to be processed sent to the feeding end of the conveying mechanism is the same in each time period, ensuring that the time variable will not affect the tea leaves The feeding and transportation of fresh leaves will be affected, and the delay in feeding will be prevented from causing the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com