Ejector, chilled beam tail end and chilled beam system

A technology of ejector and chilled beam, applied in chilled beam system, ejector, chilled beam end field, can solve the problems of high control technology and detection feedback technology, high application cost and unnecessary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

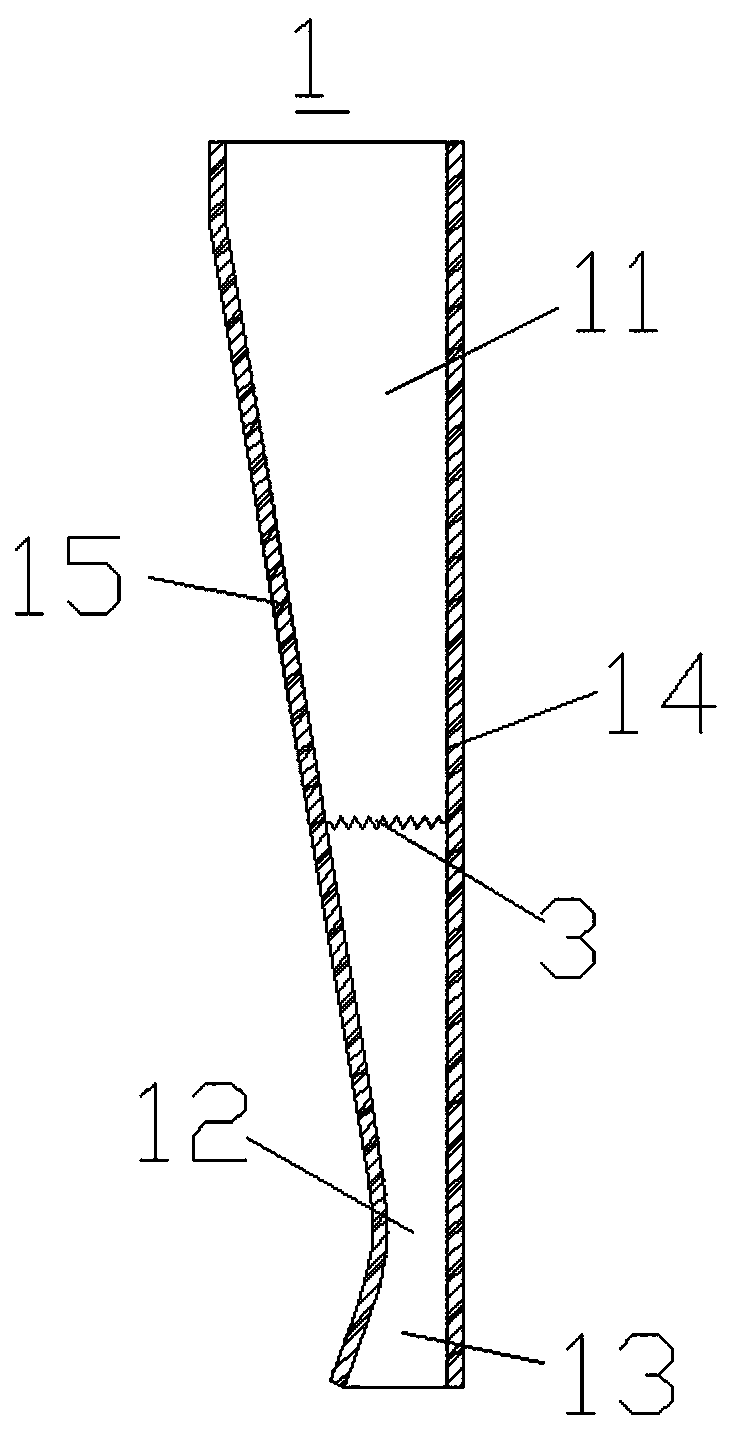

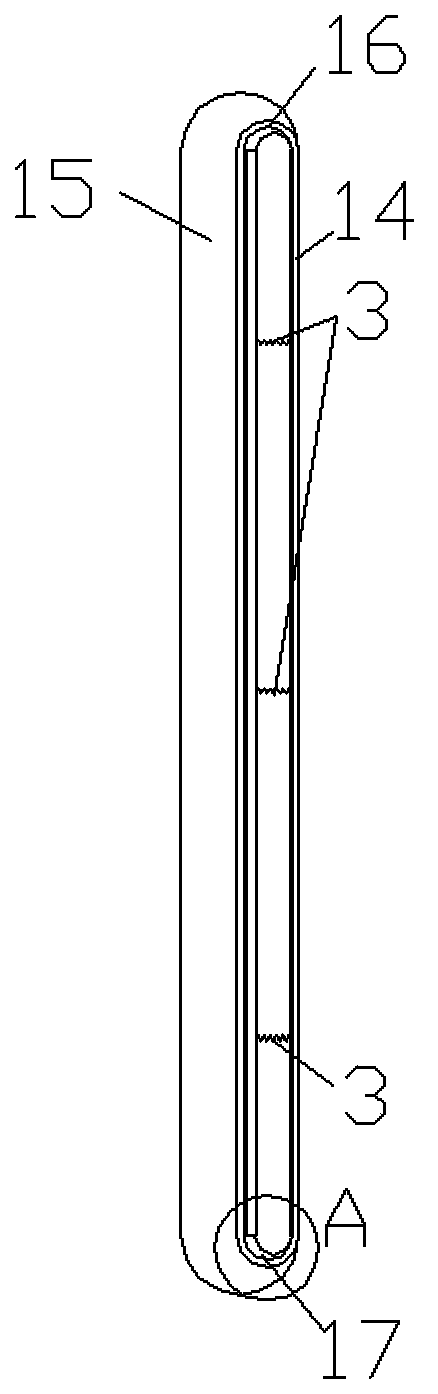

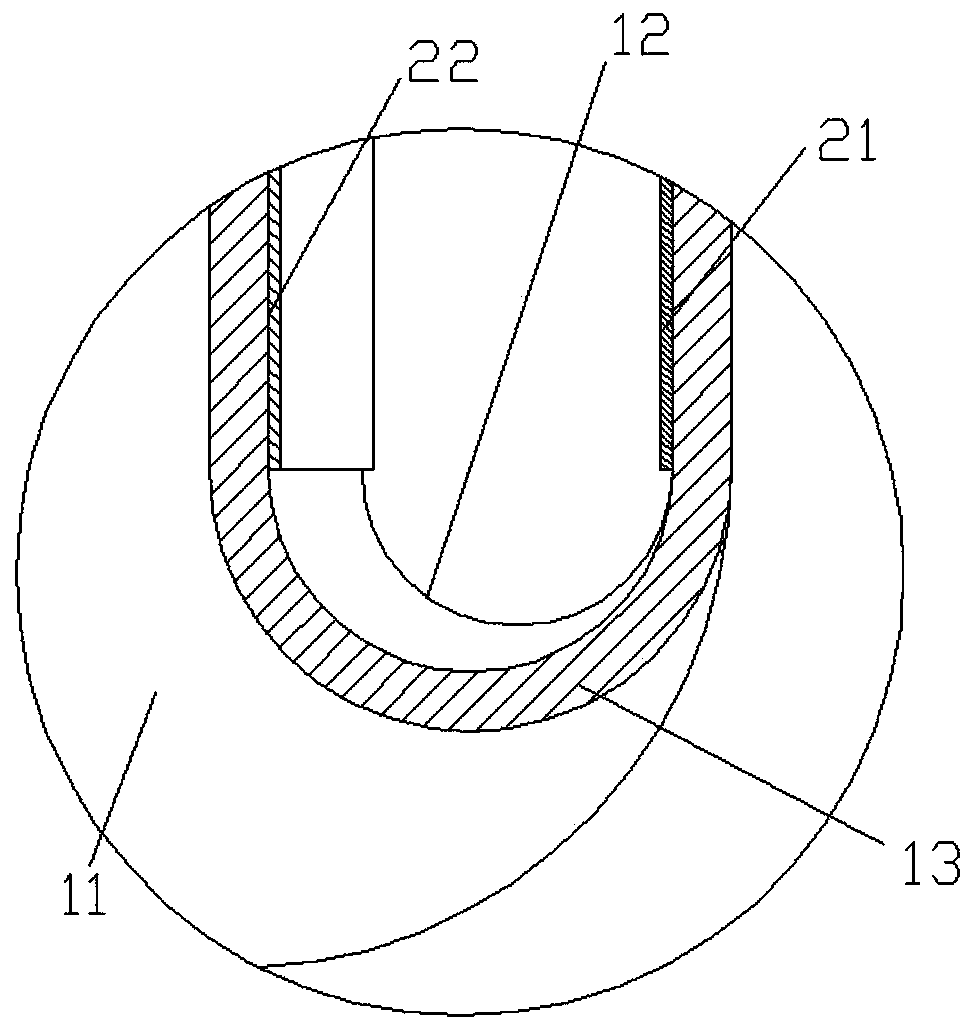

[0023] see in conjunction Figure 1 to Figure 4 As shown, according to an embodiment of the present invention, an injector is provided for use in the end of a chilled beam, comprising a nozzle housing 1, the nozzle housing 1 includes an airflow introduction section 11 for introducing primary air, for The nozzle throat 12 for throttling and accelerating the introduced primary air, and the airflow output section 13 for ejecting the throttled and accelerated primary air, the nozzle throat 12 is located between the airflow introduction section 11 and the airflow output section Between 13, when the wind pressure of the primary wind changes, the nozzle housing 1 can be elastically deformed to change the flow area of the nozzle throat 12 . In this technical solution, since the nozzle housing 1 can be elastically deformed, when the primary wind pressure therein changes, the nozzle housing 1 will undergo elastic deformation under the action of the primary wind pressure, thereby The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com