A non-excavation pipeline lining method pipeline repair layer connection method

A technology for pipeline repair and repair layer, which is applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc. It can solve the problems of difficult operation, small diameter of pipes, and excessively long pipes, so as to achieve simple procedures and low environmental impact. , the effect of reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

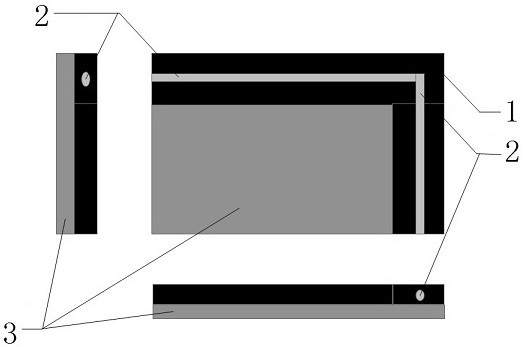

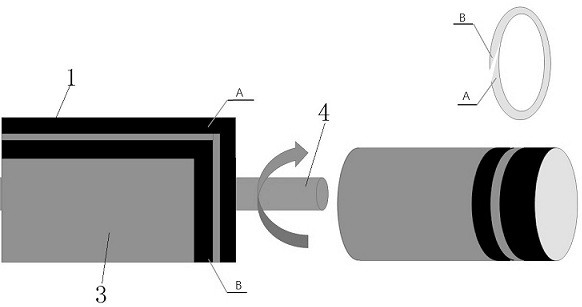

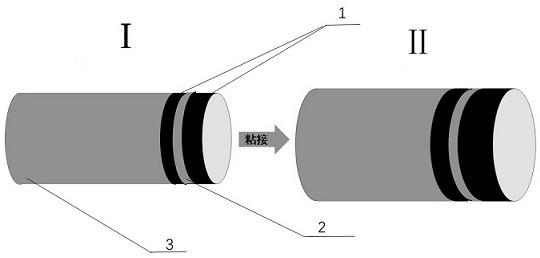

[0019] Such as Figure 1-3 Shown is a method for connecting a repair layer of a non-excavation pipeline 4 lining method pipeline 4, the repair layer is composed of a plurality of repair materials wrapped on the lining method pipeline 4, and the repair material is made of thermoplastic superglue 1 , resistance wire 2, and composite cloth 3, the composite cloth 3 is wrapped on the lining method pipe 4, the thermoplastic superglue 1 is arranged on the composite cloth 3 in an L shape, and the resistance wire 2 is pre-embedded in the thermoplastic superglue In glue 1; the specific connection method of the lining method pipeline 4 repair layer is as follows:

[0020] (1) Prefabrication of repair materials: Pre-embed the resistance wire 2 in an L shape in the thermoplastic superglue 1: fix the L-shaped resistance wire 2 in the L-shaped mold, and heat the thermoplastic superglue 1 until it melts and flows in a nitrogen atmosphere After the state, it is poured into the mold, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com