An experimental device for visually simulating the flow law of self-supporting fracturing fluid under pressure

An experimental device and fracturing fluid technology, applied in the fields of production fluids, wellbore/well components, buildings, etc., can solve the problems of inability to operate continuously, limited migration distance of carrying quartz sand, and small particle size of sand, and achieve optimization. The formula and construction parameters and process, the effect of simple processing and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

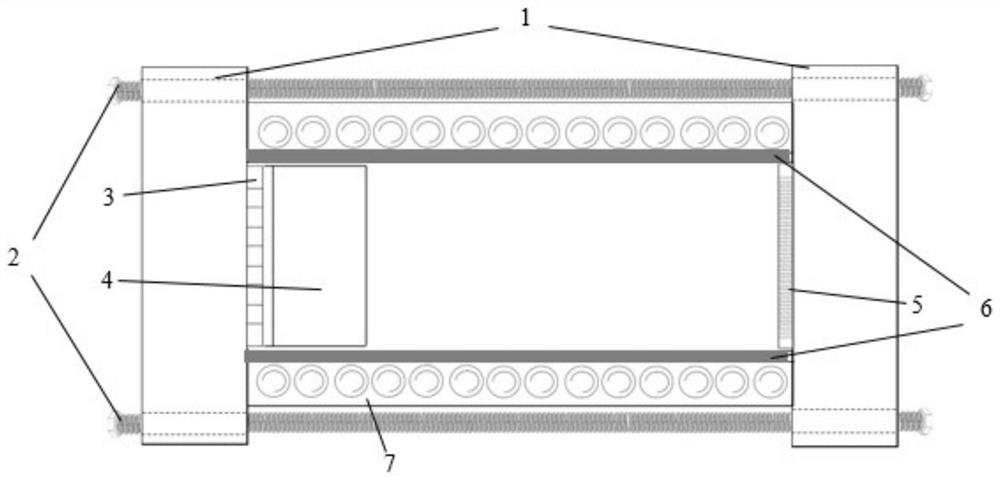

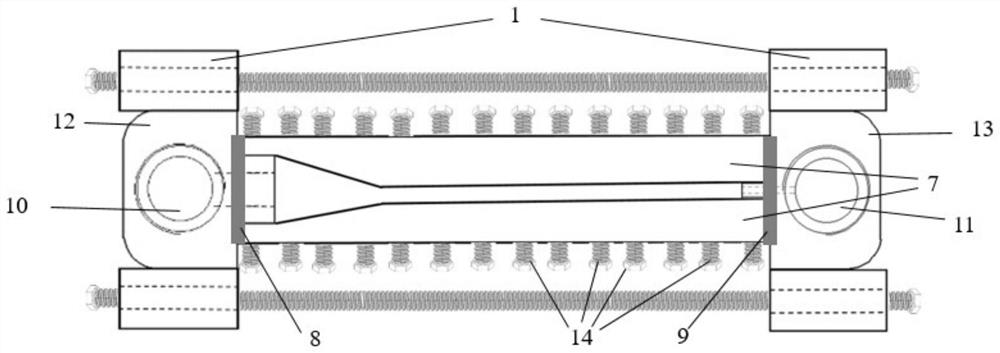

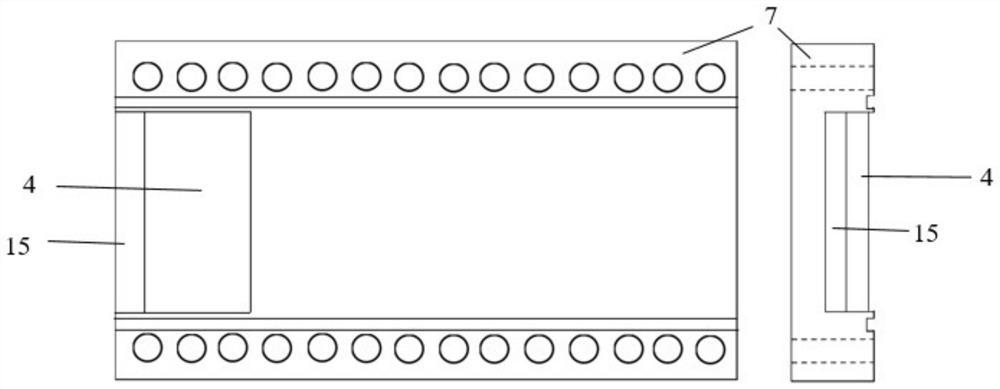

[0069] The flow process of the self-supporting fracturing fluid system in the experimental device for visually simulating the flow distribution of the self-supporting fracturing fluid under pressure is as follows. First, the self-supporting fracturing fluid and channel fracturing fluid are driven by different nitrogen bottles and liquid irrigation Replaced to the injection end threaded hole 10 on the lower side (the upper threaded hole is sealed by a plug at this time), after the self-supporting fracturing fluid system passes through the inner cavity of the injection end, it passes through the inflow end to simulate the blast hole channel 3 under the action of fluid pressure After entering the conical flow space formed by the upper and lower plexiglass 7, it enters the parallel fracture space after shearing, and then the self-supporting fracturing fluid system quickly flows to the simulated fracture tip channel 5 at the outflow end, and enters the inner cavity of the outflow end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com