Folding type safety guardrail device

A safety guardrail and folding technology, which is applied in the field of folding safety guardrail devices, can solve the problems of hindering the normal use of mechanical equipment, increasing the safety risk of high-altitude borders, and lack of protective measures, so as to avoid the state of border operations and reduce deformation and damage , Guarantee the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0051] see Figure 10 , the difference between this embodiment and Embodiment 1 is:

[0052] The folding mechanism includes a middle cross bar 34 and several connecting rods 32. The middle cross bar 34 is located between the upper rail 31 of the movable guardrail and the fixed guardrail 2, and between the upper rail 31 of the movable guardrail and the middle cross bar 34. And between the fixed guardrail 2 and the middle cross bar 34, some parallel connecting rods 32 are respectively provided with in a hinged manner. The plumb line forms an isosceles triangle or is collinear with the plumb line.

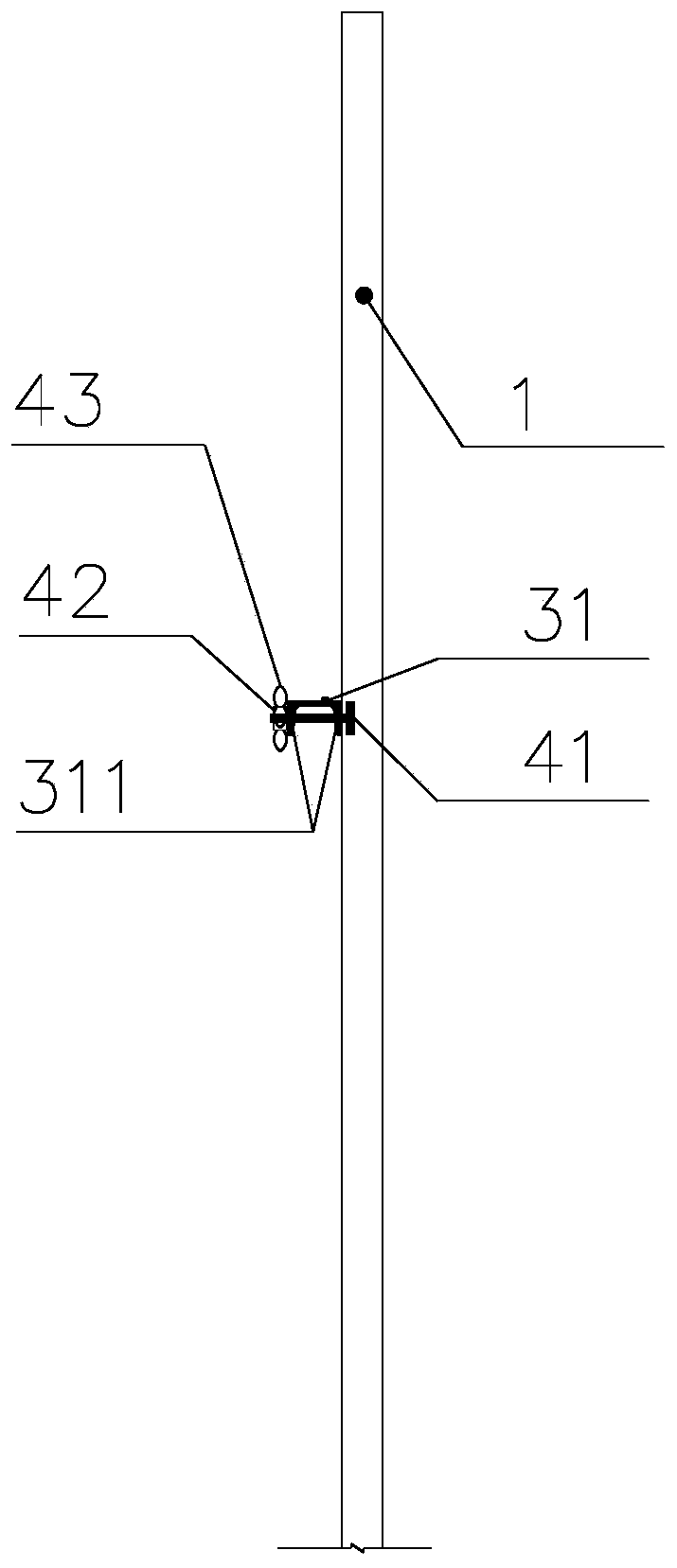

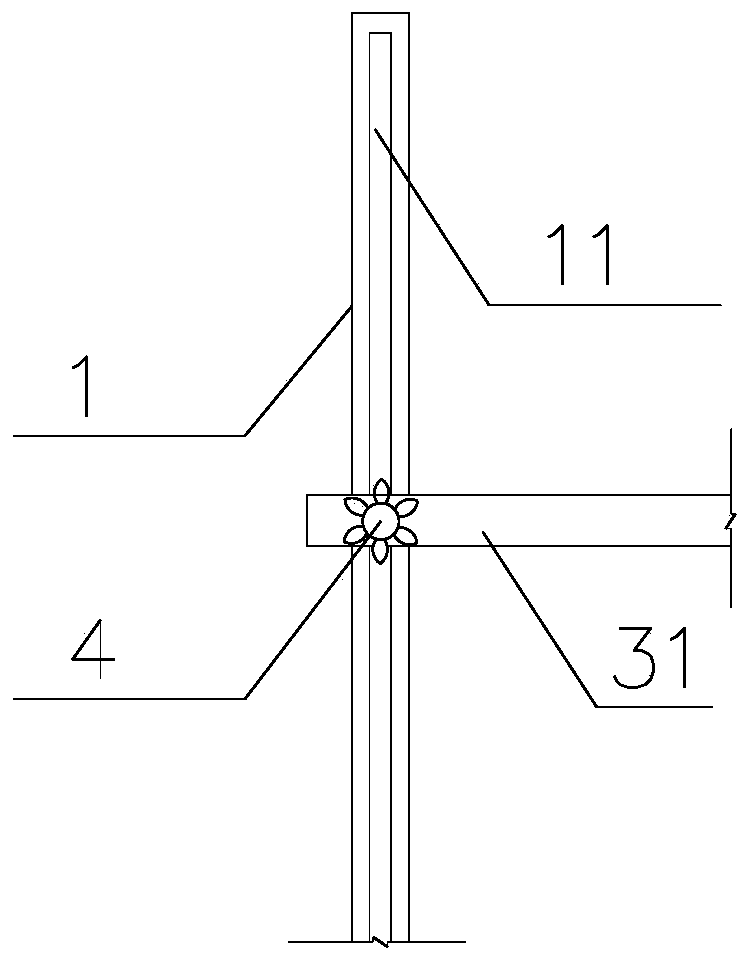

[0053] And the structure of the guardrail height locking mechanism 4 is different from that of Embodiment 1. Specifically, the guardrail height locking mechanism 4 includes bolts 41 and nuts 42. The fixed column 1 is provided with a vertical chute 11, and the movable guardrail is provided with a vertical chute. The gear 31 is provided with a through hole for the bolt 41 rod of the b...

Embodiment 3

[0058] see Figure 11 , the difference between this embodiment and embodiment two is:

[0059] The folding mechanism includes a middle cross bar 34 and several rhombic connecting components, the middle cross bar 34 is located between the upper rail 31 of the movable guardrail and the fixed guardrail 2, and the upper rail 31 of the movable guardrail and the middle cross bar 34 And between the fixed guardrail 2 and the middle cross bar 34, several rhombic connecting assemblies are respectively arranged in a hinged manner, and the rhomboid connecting assemblies are formed by four connecting rods 32 end-to-end hinged. In this way, the use of the middle cross bar 34 can be reduced, and the construction cost can be reduced.

Embodiment 4

[0061] see Figure 12 , the difference between the present embodiment and the third embodiment is:

[0062] Described folding mechanism comprises several connecting assemblies, and described connecting assembly comprises by six connecting rods 32, and six connecting rods 32 are positioned at the vertical plane that movable guardrail upper shelf 31 and fixed column 1 constitute, and wherein four connecting rods 32 head and tail Hinged to form a rhombus connector, one end of the other two connecting rods 32 is respectively hinged with the upper end or lower end of the rhombus connector, and the other end is respectively hinged with the upper rail 31 of the movable guardrail or the fixed guardrail, and several connecting assemblies are arranged horizontally. The rhombus connectors of adjacent connection group assemblies are hinged at butt vertices. The strength of the upper rail 31 of the movable guardrail of this embodiment is higher than that of Embodiment 3, and the stability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com