Climbing belt type climbing safety facility for tower crane

Technology of a tower crane, safety facility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

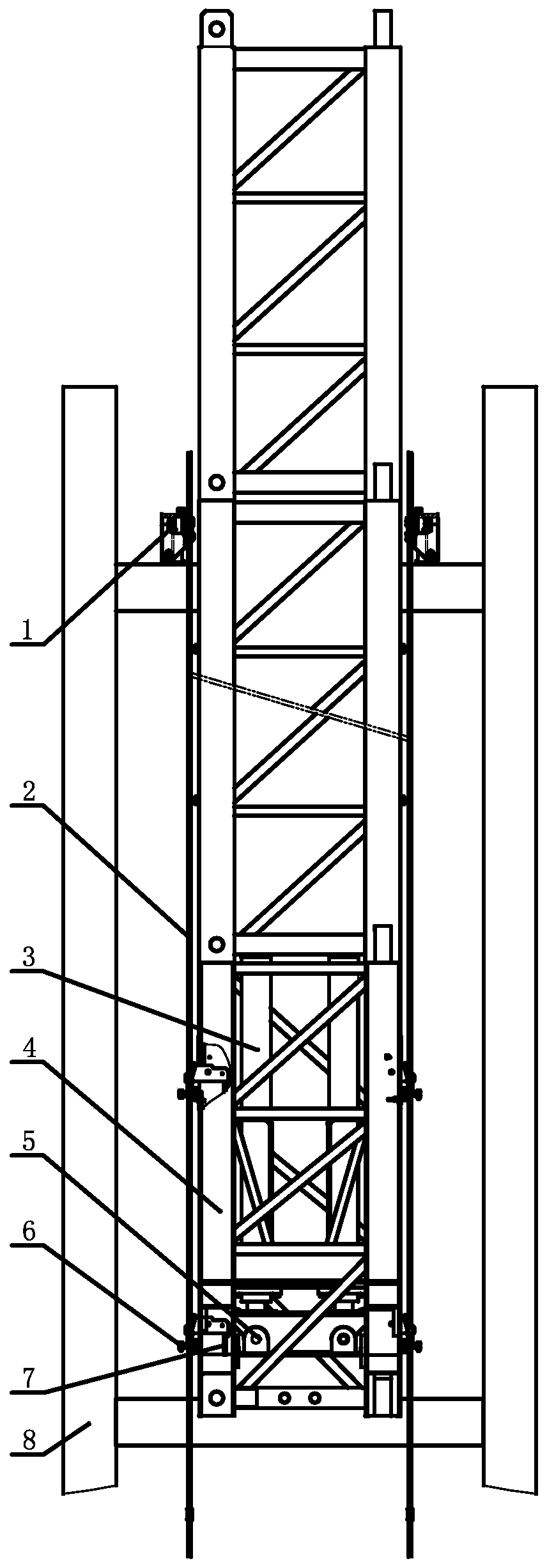

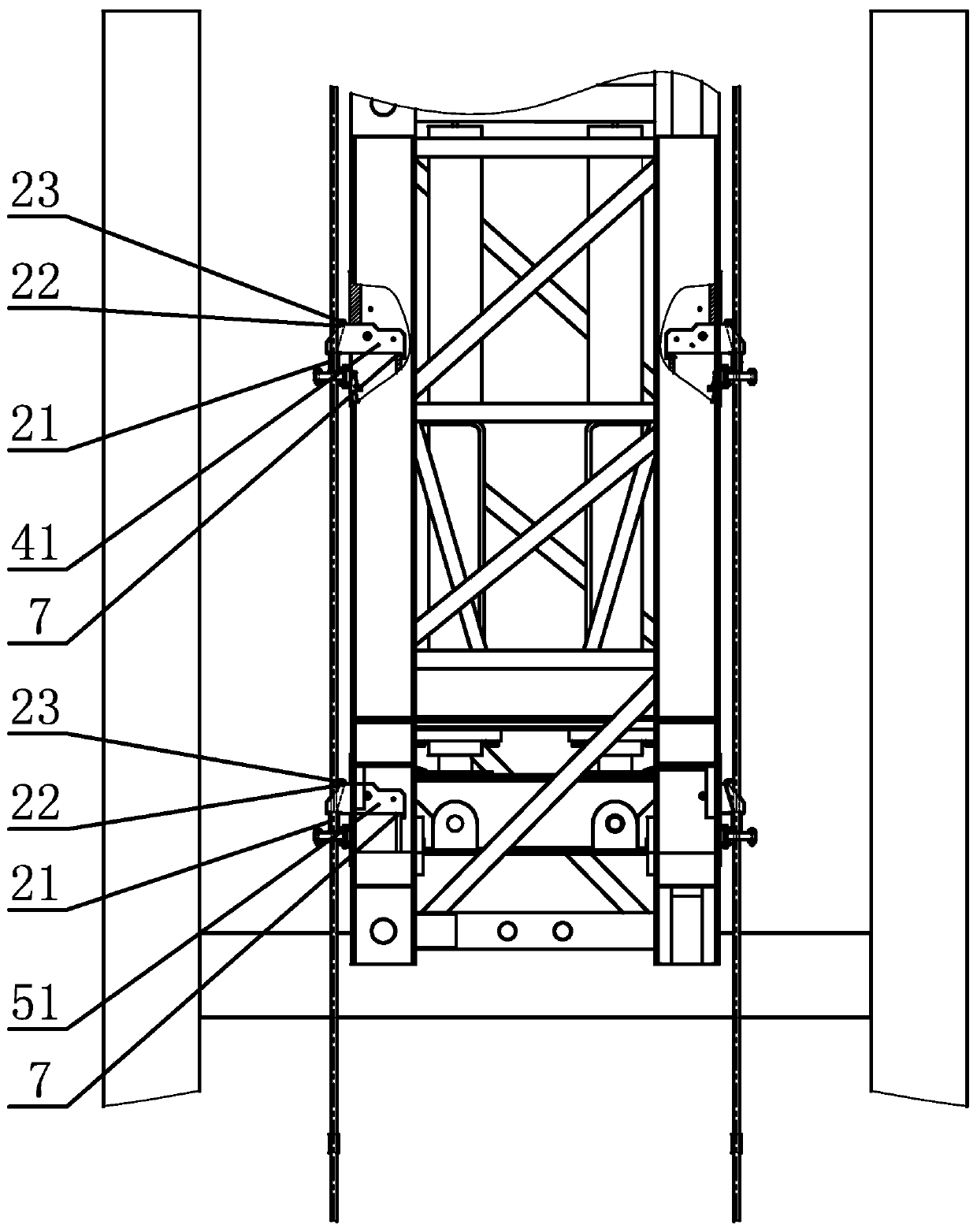

[0049] Example: such as figure 1 , figure 2 As shown, a climbing belt type climbing safety facility for a tower crane in the present invention includes a climbing belt 2, a climbing belt holder 6 and a climbing claw restraint device, and the climbing belt holder 6 is arranged at both ends of the tower crane jacking beam 5 and the positions close to the supporting claws 41 on both sides of the climbing section 4 of the tower crane, the guide rails on both sides of the climbing belt 2 pass through the chute of the climbing belt cage 6, and the climbing belt cage 6 slides along the climbing belt 2 during the climbing process of the tower crane , to ensure that the climbing belt 2 and the rotating support shaft 52 of the climbing claw 51 have a relatively fixed horizontal distance; the climbing claw restraining device is arranged on the climbing belt 2, close to the position of the step 21, and constrains the crawling claw to the climbing belt step 21, When the hydraulic cylinde...

Embodiment 2

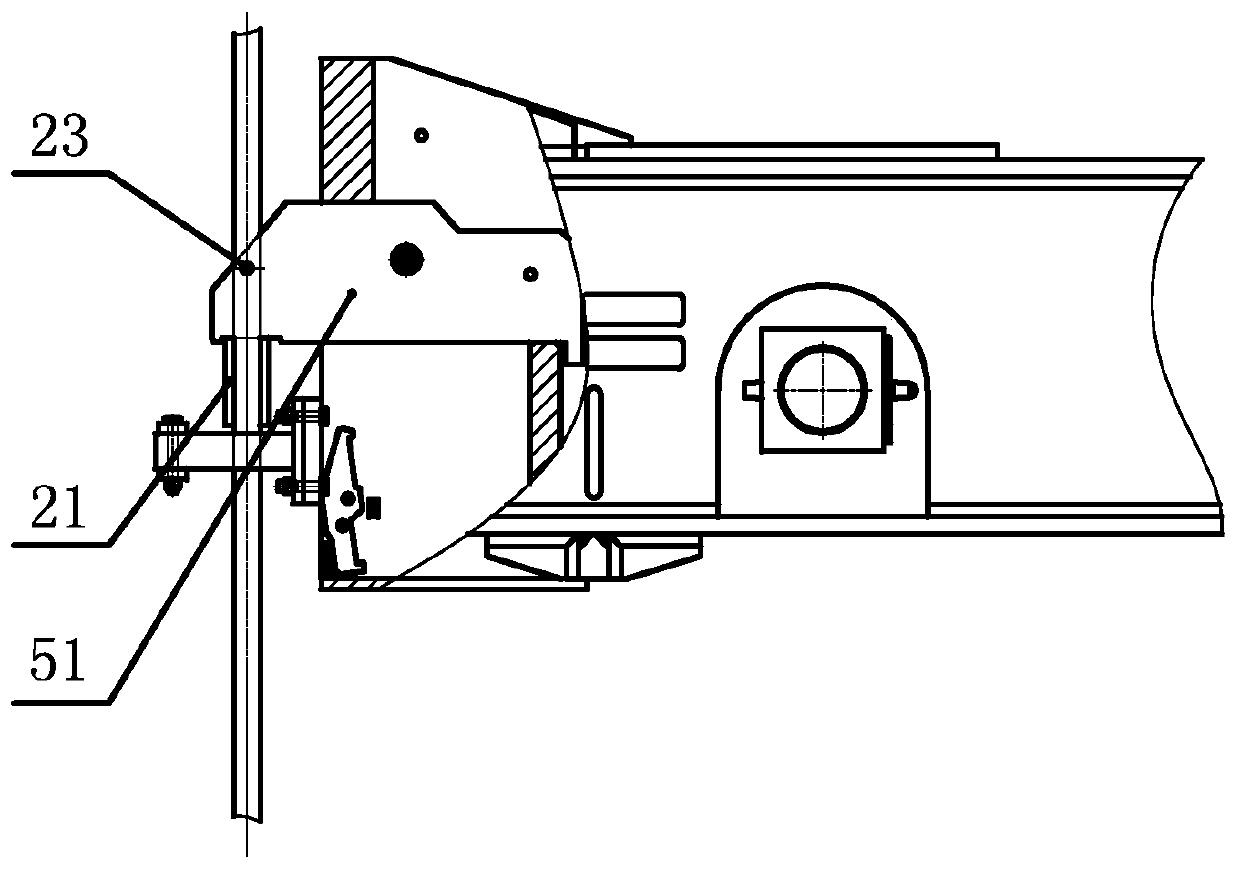

[0058] Embodiment 2: The difference between this embodiment and Embodiment 1 is: taking the climbing claw constraint on the jacking beam 5 as an example, as image 3 As shown, the climbing belt restraint device described in this example has climbing claw restraining rod mounting holes correspondingly on the climbing claw 51 and the climbing belt 2, after the climbing claw 51 steps on the step 21 of the climbing belt 2, through Claw 51 and crawler belt 2 corresponding restraint rod installation holes penetrate climbing claw restraint rod 23, and this example climbs claw restraint rod 23 and adopts pin shaft, and restrains crawler claw 51 at crawler belt stepping 21 places. In the locked state of the crawling paw restraint rod 23, it is ensured that the lifting movement of the hydraulic cylinder can be stuck, so as to prevent the hydraulic cylinder from misoperation and causing telescopic movement that endangers safety. The hole of the restraining rod of the climbing claw can al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com