Outdoor garbage can with a garbage compression function

A technology of garbage compression and garbage can, applied in the field of garbage cans, can solve the problems of filling the interior space of the garbage can, consuming human resources, affecting garbage dumping, etc., to achieve the effect of convenient garbage dumping, saving manpower, and saving space in the bucket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

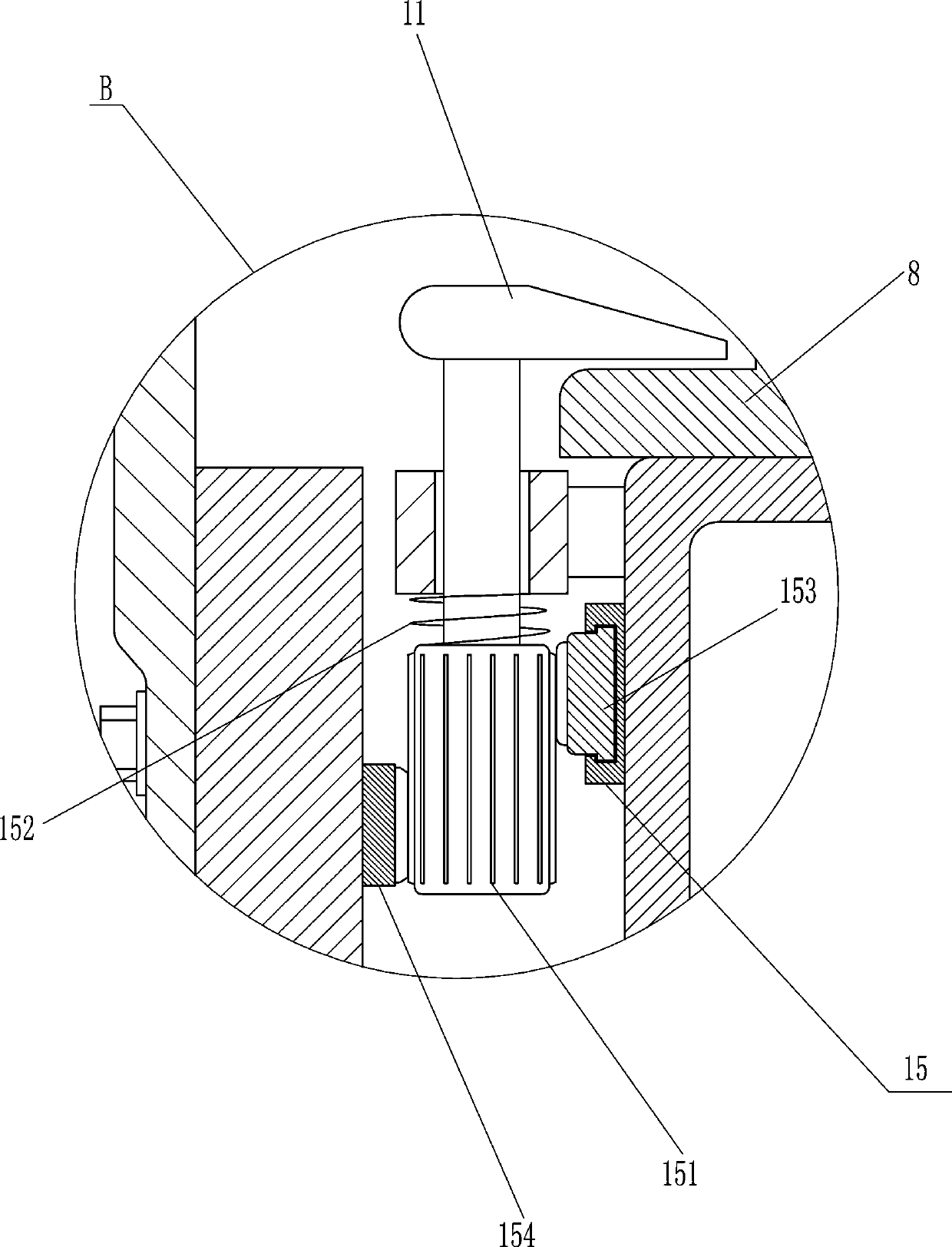

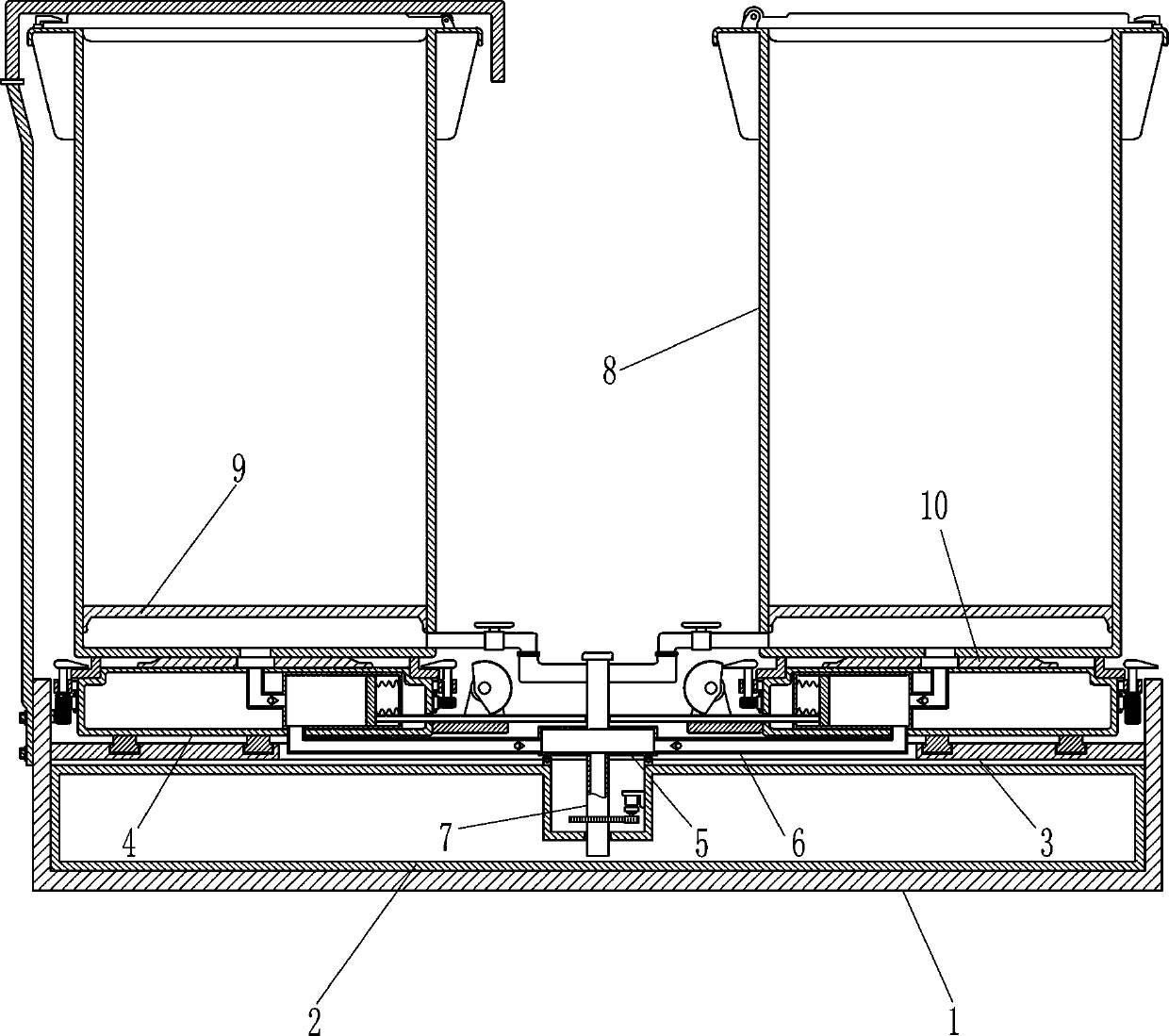

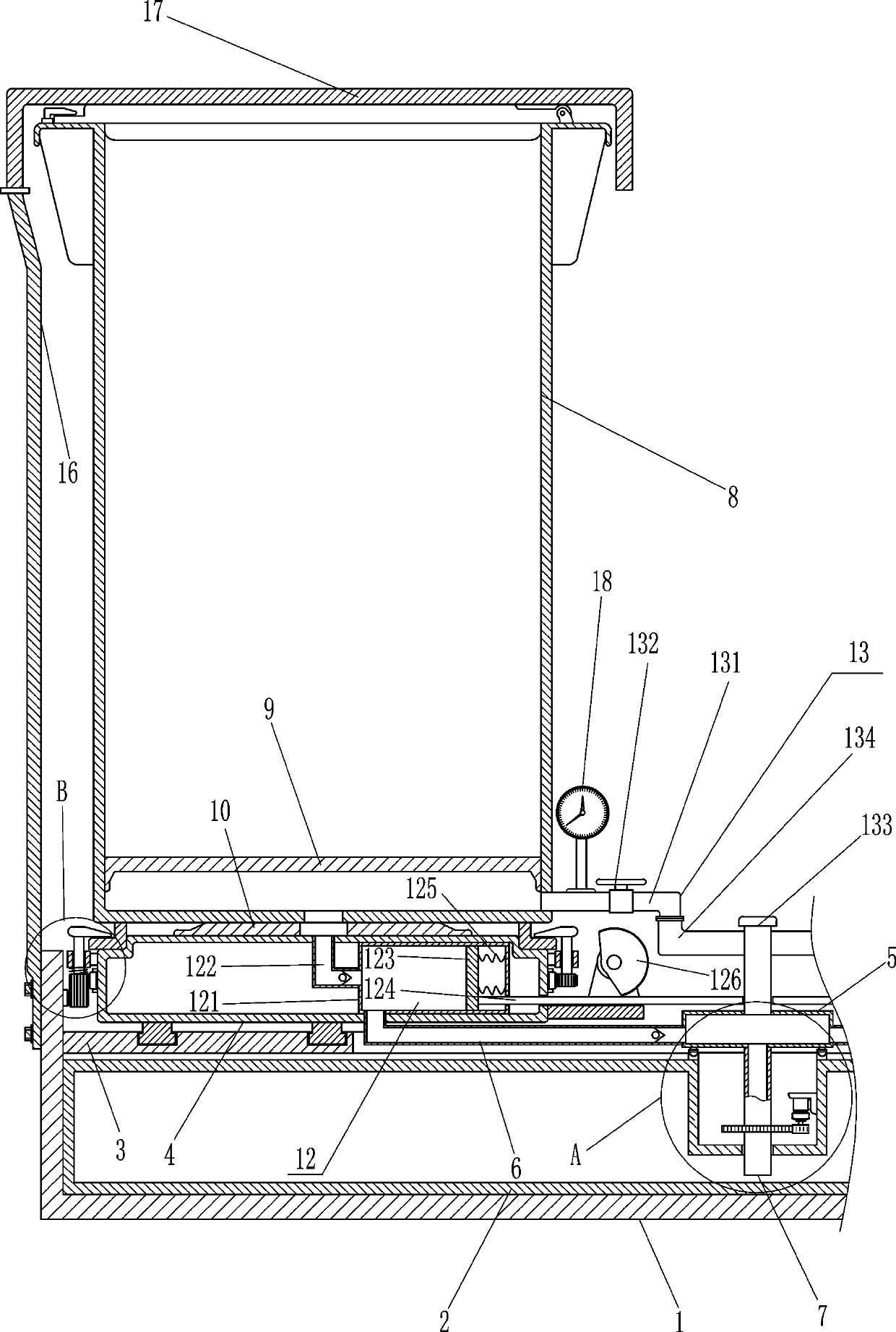

[0021] see figure 1 , figure 2 and Figure 4 , an outdoor trash can with a garbage compression function, including a base 1, a water tank 2, an annular plate 3, a support frame 4 and a disc 5, the inner bottom of the base 1 is provided with a water tank 2, and the water tank 2 is connected to the base by bolts 1 is connected with each other, the inner middle of the base 1 is connected with an annular plate 3, and the top of the annular plate 3 is provided with four support frames 4 which are slid evenly spaced along the circumferential direction, and the top of the water tank 2 is provided with a disc 5 which is rotated in the middle, and also includes a one-way Connecting pipe 6, water inlet pipe 7, trash can 8, push plate 9, sealing gasket 10, clamping rod 11, pushing assembly 12 and water return assembly 13, disc 5 is connected with four one-way connecting pipes 6 evenly spaced along the circumferential direction , the end of the one-way connecting pipe 6 extends into th...

no. 2 example

[0028] see image 3 , also includes a rotating assembly 14, the rotating assembly 14 includes a large gear 141, a reduction motor 142 and a small gear 143, the bottom of the water inlet pipe 7 is connected with a large gear 141, and the water inlet pipe 7 is connected with the large gear 141 by a key connection, The large gear 141 is located above the water tank 2, and the outer wall of the water tank 2 is connected with a reduction motor 142, and the output shaft of the reduction motor 142 is connected with a pinion 143, and the output shaft of the reduction motor 142 is connected with the pinion 143 by a coupling. The pinion gear 143 meshes with the bull gear 141 .

[0029] When the support frame 4 needs to be rotated, start the deceleration motor 142 to drive the pinion 143 to rotate, the pinion 143 rotates to drive the large gear 141 to rotate, the large gear 141 rotates to drive the disc 5 to rotate through the water inlet pipe 7, and the disc 5 rotates through the one-wa...

no. 3 example

[0033] refer to figure 2 , also includes a connecting plate 16 and a baffle plate 17, the upper part of the outer left wall of the base 1 is connected with a connecting plate 16, the connecting plate 16 is connected with the base 1 by bolts, and the top of the connecting plate 16 is provided with 8 barrels for fixing the garbage can Cover baffle 17 , baffle 17 is parallel to base 1 .

[0034] When the rotary assembly 14 drives the garbage can 8 to rotate to the left side of the base 1, the baffle plate 17 blocks the lids of the garbage cans 8, so that there is no need to manually lock the lids of the garbage cans 8, which makes the operation easier.

[0035] refer to figure 2 , also includes a pressure gauge 18, and the drain cannula 131 is provided with a pressure gauge 18 for detecting the water pressure in the trash can 8.

[0036] When the pushing assembly 12 injects liquid into the garbage can 8, the pressure gauge 18 can test the pressure of the liquid in the garbage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com