A new type of screen sound exciter and its implementation method

A screen sound generation and implementation method technology, applied in the direction of sensors, telephone structures, branch office equipment, etc., can solve the problems that hinder the development of the screen-to-body ratio and no longer meet the needs, and achieve good sound effect, large driving force, and convenient manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

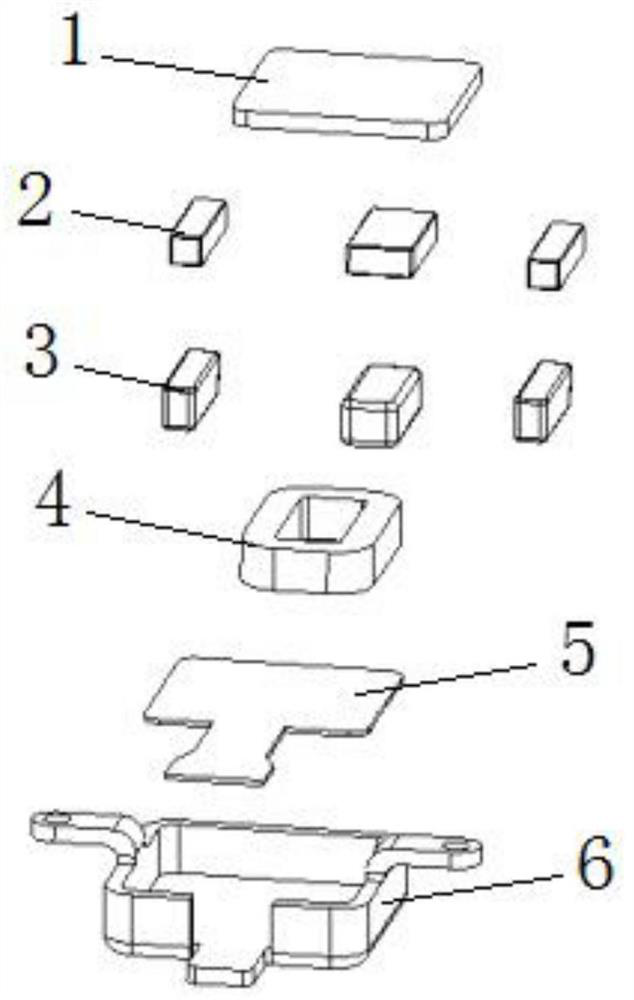

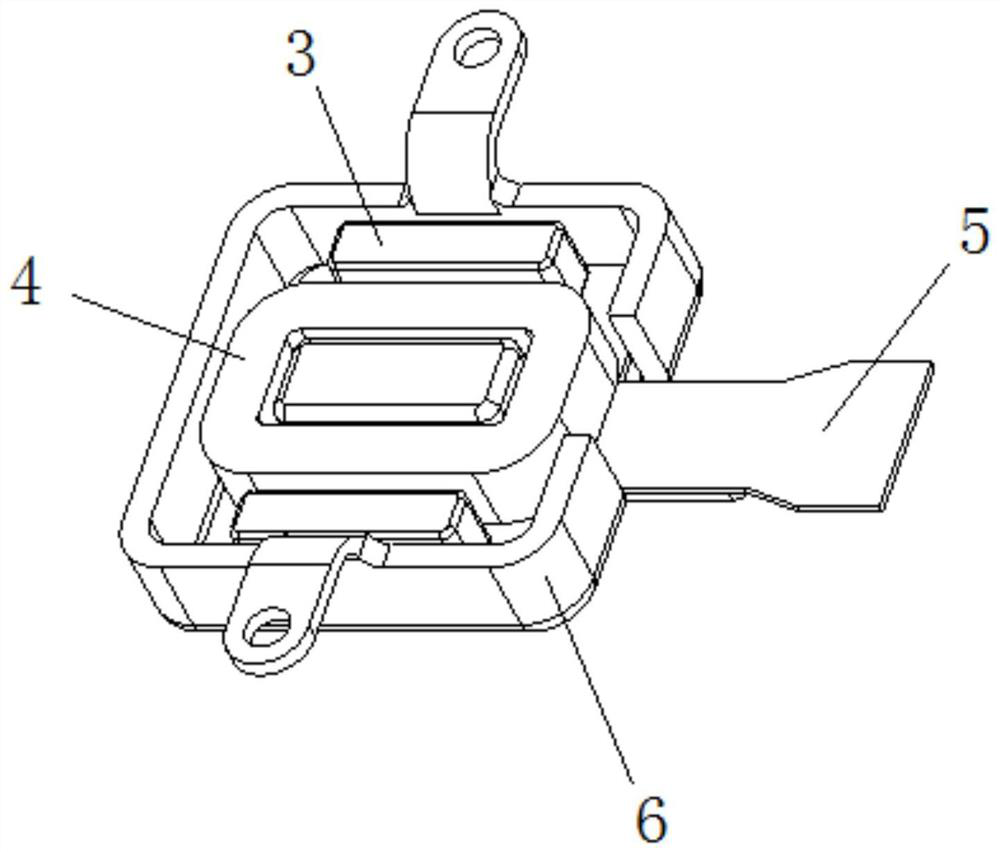

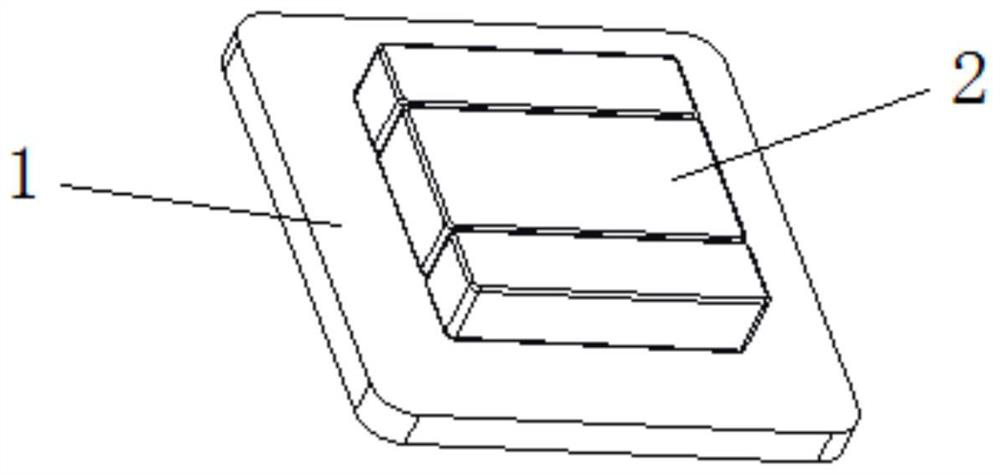

[0031] see Figure 1-5 , the present invention provides the following technical solutions: a novel screen sound exciter, including a vibrating assembly 8 and a stator assembly 9, the vibrating assembly 8 includes a magnetic conductive plate 1 and a magnetic steel group 2, wherein one side of the magnetic conductive plate 1 is connected with The magnetic steel group 2, the stator assembly 9 includes a coil 4, a flexible circuit board 5 and a lower bracket 6, wherein a flexible circuit board 5 is connected to the inside of the lower bracket 6, and a coil 4 is connected to the top of the flexible circuit board 5, and the flexible circuit board 5 is flexible. The circuit board 5 is electrically connected to the coil 4 , and the vibration component 8 is located above the stator component 9 .

[0032] Further, the magnet group 2 includes three magnets, and the three magnets are arranged side by side.

[0033] By adopting the above technical scheme, the S-level of the middle magneti...

Embodiment 2

[0046] This embodiment differs from Embodiment 1 in that further, the iron core group 3 includes three iron cores, one iron core is located inside the coil 4 , and the other two iron cores are respectively located on both sides of the coil 4 .

[0047] By adopting the above technical solution, the magnetic field lines around the coil 4 are concentrated by the iron core, and the intensity of the magnetic field is enhanced.

[0048] To sum up, the present invention connects the vibrating component to the screen, connects the stator component to the middle frame, and through the interaction between the stator component and the vibrating component, drives the screen to vibrate along the Z axis to achieve the effect of sounding, with a simple structure , easy to manufacture, good sounding effect, and high energy utilization rate; the invention connects three magnetic steels arranged side by side on the magnetic permeable plate, thereby increasing the magnetic field intensity generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com