Aerodynamic design method of high-performance ship gas turbine compressor

A pneumatic design and compressor technology, applied in geometric CAD and other directions, can solve problems such as small adaptability and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

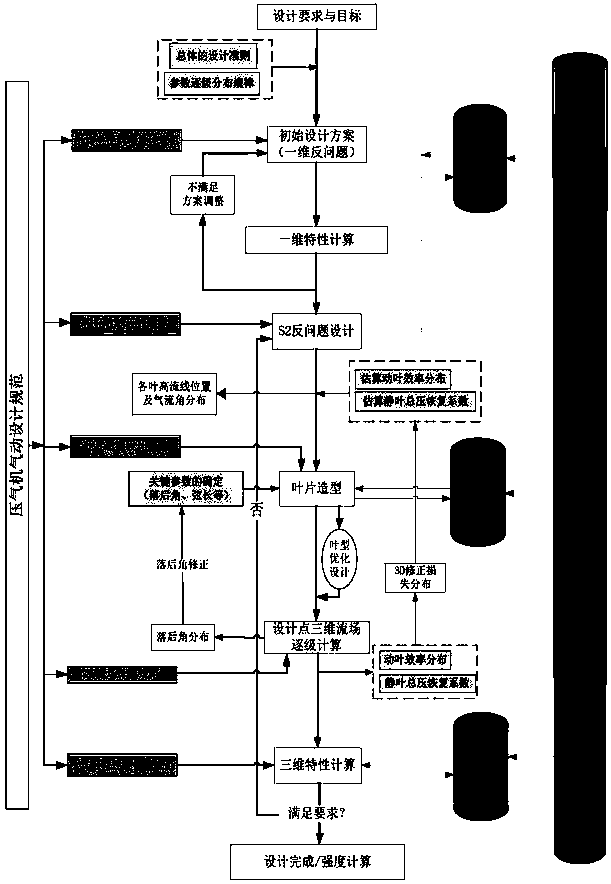

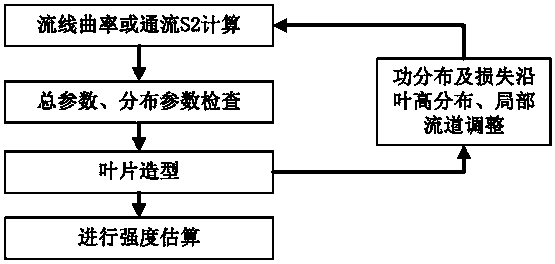

[0021] Specific implementation mode one: refer to figure 1 To illustrate this embodiment, the aerodynamic design method of a high-performance marine gas turbine compressor described in this embodiment includes the following steps:

[0022] Step 1. Refer to figure 1 , according to the design requirements and goals, and in accordance with the overall design requirements of the compressor, the one-dimensional inverse problem design of the multi-stage axial flow compressor is carried out, and multiple schemes are obtained. At the same time, the designed schemes can also be stored as data resources in the compressor pneumatic in the design database;

[0023] The basic parameters of the compressor are selected according to the average radius aerodynamic design specification. Many parameters in this process are selected based on design experience. You can check the relevant unit design data with the help of the compressor basic parameter database, and perform multi-plan optimization...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the step 1 is designed to violate the problem, and the main tasks include: according to the given flow rate and pressure ratio, estimate the efficiency of the compressor and the main geometric parameters, based on experience relationship, determine the preliminary design scheme of the compressor, and obtain the basic conditions of the compressor's rotation angle, blade height, chord length, number of blades, inner and outer diameters, and angle of attack (the main parameters of the one-dimensional design of the compressor are shown in Table 1):

[0027] Table 1 Main parameters of one-dimensional aerodynamic design of a typical compressor

[0028]

[0029] In the process of designing one-dimensional inverse problems, attention should be paid to the selection of the following parameters:

[0030] Axial speed: The selection of the axial speed of the inlet stage needs to compr...

specific Embodiment approach 3

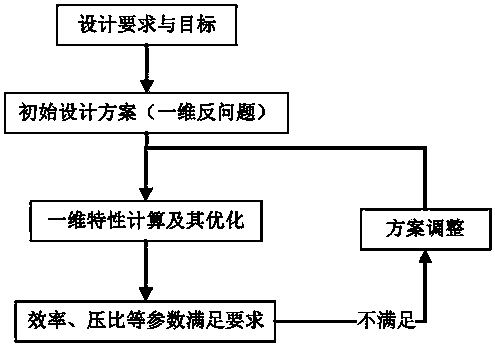

[0032]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the step 1 is to calculate and optimize the characteristics of the compressor; the specific process is:

[0033] In the one-dimensional characteristic calculation and optimization stage, the AXIAL software module in the Concepts-NREC engineering design system is used. This software provides the design calculation of multi-stage axial flow compressors and turbomachinery, as well as the existing units or design schemes. The analysis function can also be used to predict and analyze the performance of turbomachinery under variable conditions. In the one-dimensional characteristic calculation and optimization stage, the analysis mode is adopted, and the design results of the compressor flow obtained by the one-dimensional inverse problem, that is, the geometric parameters of the blade rows at all levels, are checked and calculated by means of the analysis mode of the program software, and repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com