Anti-vibration direct current shunt for measuring impact current

A technology of inrush current and shunt, which is applied in the direction of test/measurement connectors, current-only measurement, and measurement devices, which can solve problems such as economic loss, damage, and damage to hard equipment, and achieve the effect of strong resistance to vibration and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

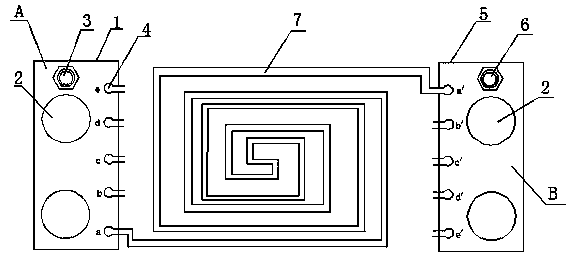

[0039] Such as figure 1 with Figure 4 The present invention includes a left connecting plate A, a right connecting plate B and a connecting body, and the connecting body connects the left connecting plate A and the right connecting plate B as a whole; the left connecting plate A includes a left conductive block body 1, a left connecting plate The left part of the conductive block body 1 is provided with a connecting hole 2 which is transparent up and down, the upper end surface of the left conductive block body 1 is provided with a left connecting bolt 3, and the right part of the left conductive block body 1 is provided with a row of concave grooves 4. The opening of the shaped groove cavity 4 faces the right end, and the left connecting plate A and the right connecting plate B have the same structure and are symmetrical; the right connecting plate B includes a right conductive block 5, and the right part of the right conductive block 5 is provided with a transparent The co...

Embodiment 2

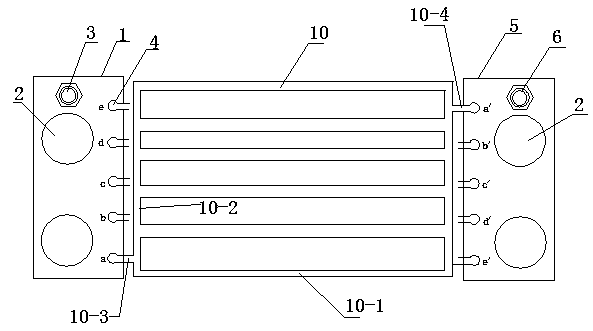

[0043] Such as figure 2 with Figure 4 As shown, the present invention includes a left connecting plate A, a right connecting plate B and a connecting body, and the connecting body connects the left connecting plate A and the right connecting plate B as one; the left connecting plate A includes a left conductive block body 1, a left connecting plate The left part of the conductive block 1 is provided with a connection hole 2 which is transparent up and down, and the connection hole 2 is used for connecting other configuration devices. The upper end surface of the left conductive block 1 is provided with a left connecting bolt 3, and the right part of the left conductive block 1 is provided with a row of concave grooves 4, the opening of the concave grooves 4 faces the right end, and the left connecting plate A and the right connecting plate The B structure is the same and symmetrical; the right connecting plate B includes a right conductive block 5, the right part of the rig...

Embodiment 3

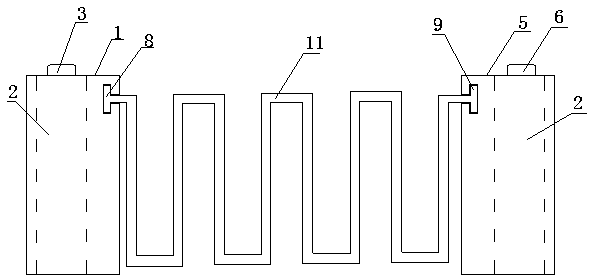

[0047] Such as image 3 with Figure 4 As shown, the present invention includes a left connecting plate A, a right connecting plate B and a connecting body, and the connecting body connects the left connecting plate A and the right connecting plate B as one; the left connecting plate A includes a left conductive block body 1, a left connecting plate The left part of the conductive block 1 is provided with a connection hole 2 which is transparent up and down, and the connection hole 2 is used for connecting other configuration devices. The upper end surface of the left conductive block 1 is provided with a left connecting bolt 3, and the right part of the left conductive block 1 is provided with a row of concave grooves 4, the opening of the concave grooves 4 faces the right end, and the left connecting plate A and the right connecting plate The B structure is the same and symmetrical; the right connecting plate B includes a right conductive block 5, the right part of the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com