High-purity NF3 intake control device and method of ultra-high vacuum system

An ultra-high vacuum and control device technology, which is used in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the problem of lack of in-depth research on the micro-precision control of the intake pipeline, and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

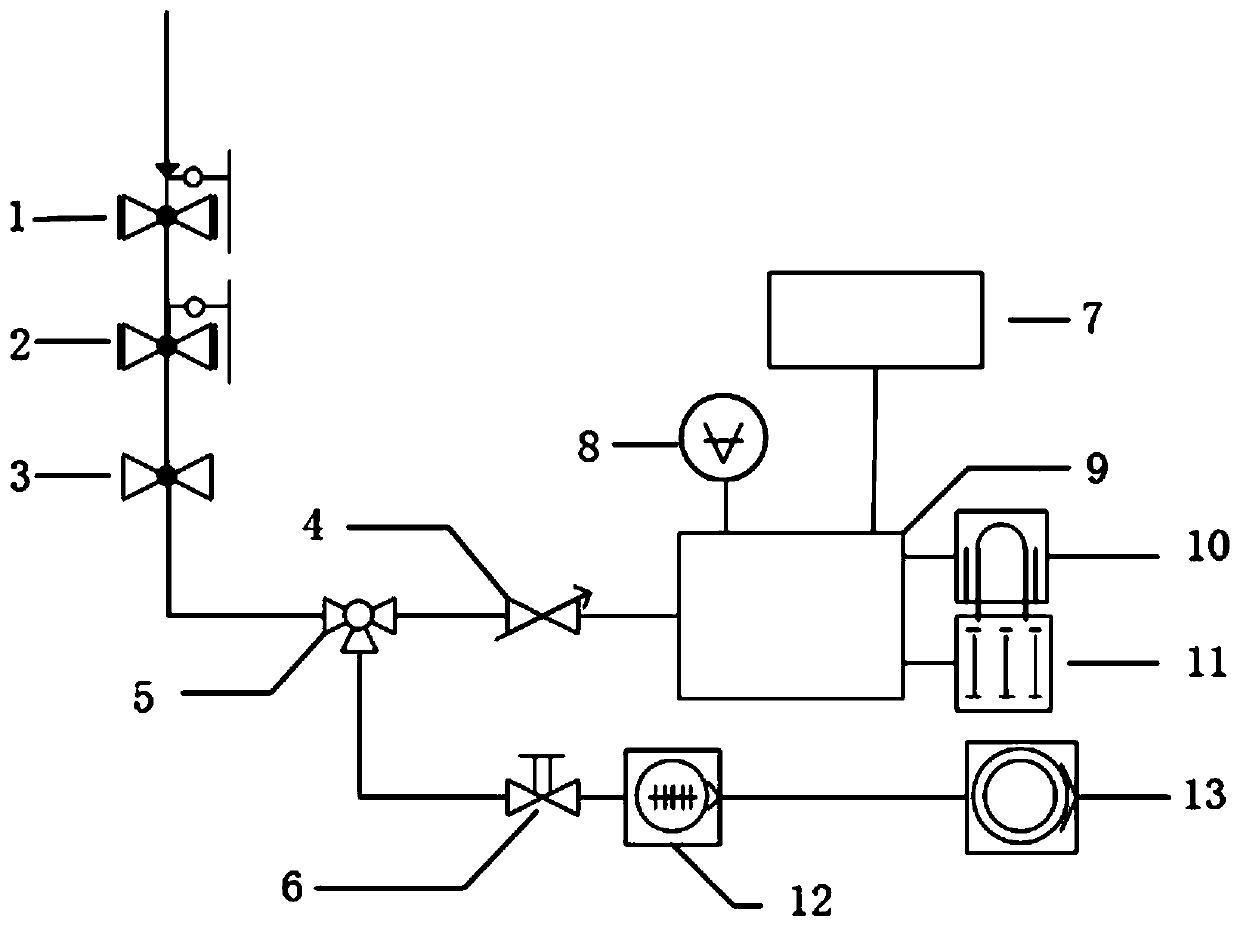

[0047] In this embodiment, a micro-control high-purity NF in an ultra-high vacuum system is set. 3 Intake device such as figure 1 As shown, the parameters are set without loss of generality.

[0048] In order to NF in the ultra-high vacuum system 3 The intake air volume is precisely fine-tuned and the residual air in the intake pipe is extracted. The present invention has certain requirements for the connection of pipeline equipment. First, if figure 1 shown, for NF 3 The requirements for the connection of the intake pipe are: NF 3 The intake pipe should be equipped with a primary pressure reducing valve 1, a secondary pressure reducing valve 2, and a ball valve 3, and then be connected with the adjustable trace intake valve 4 and the cavity of the ultra-high vacuum activation chamber 9. The front end of the valve 4 is provided with a three-way, 5-point, and one-way connection with the turbomolecular pump angle valve 6 for pumping air, and the gas pipeline can be pumped t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com