Device and method for measuring dynamic lateral strain of test piece through liquid volume

A lateral strain and liquid volume technology, applied in measuring devices, using a single impact force to test material strength, instruments, etc., can solve the problems of inaccurate lateral strain measurement, inaccurate lateral strain, uneven lateral strain, etc. , to avoid the influence of non-smooth surfaces and artificial errors, improve the measurement accuracy, and achieve the effects of reasonable measurement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

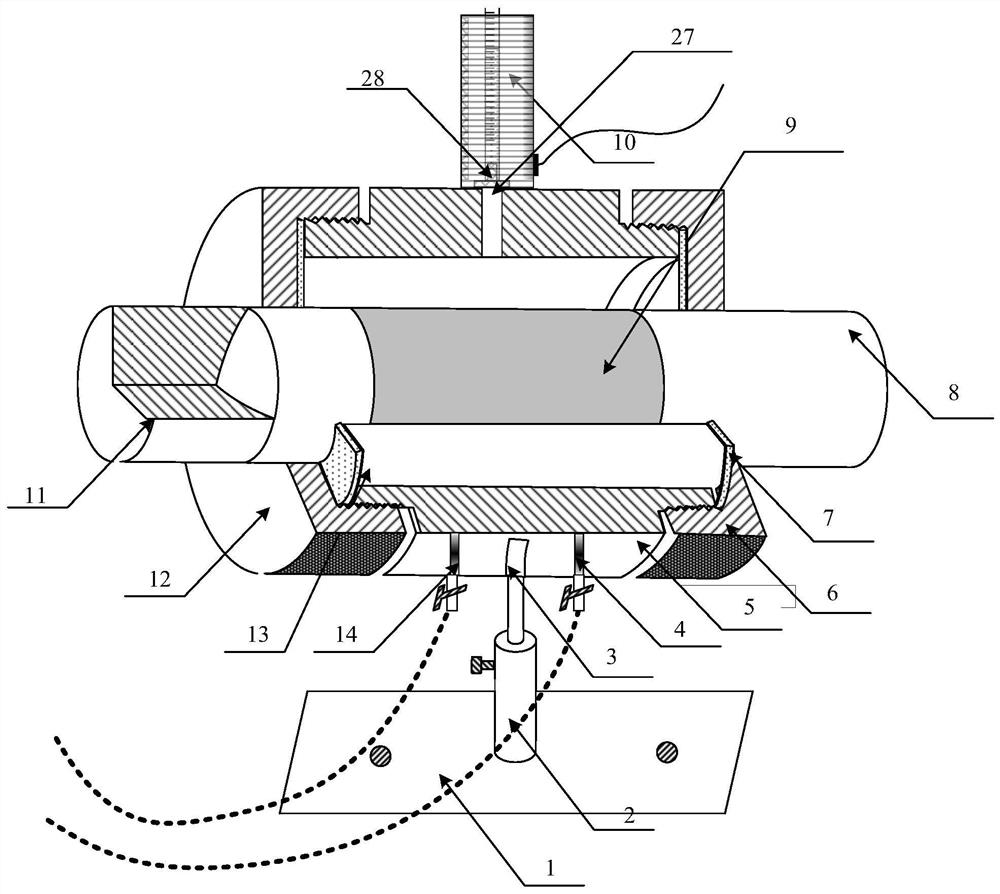

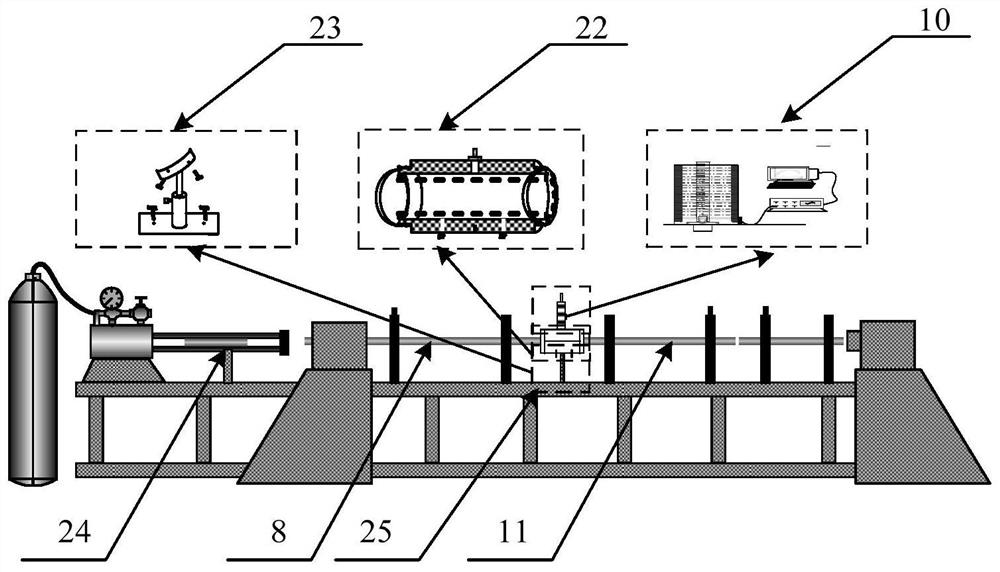

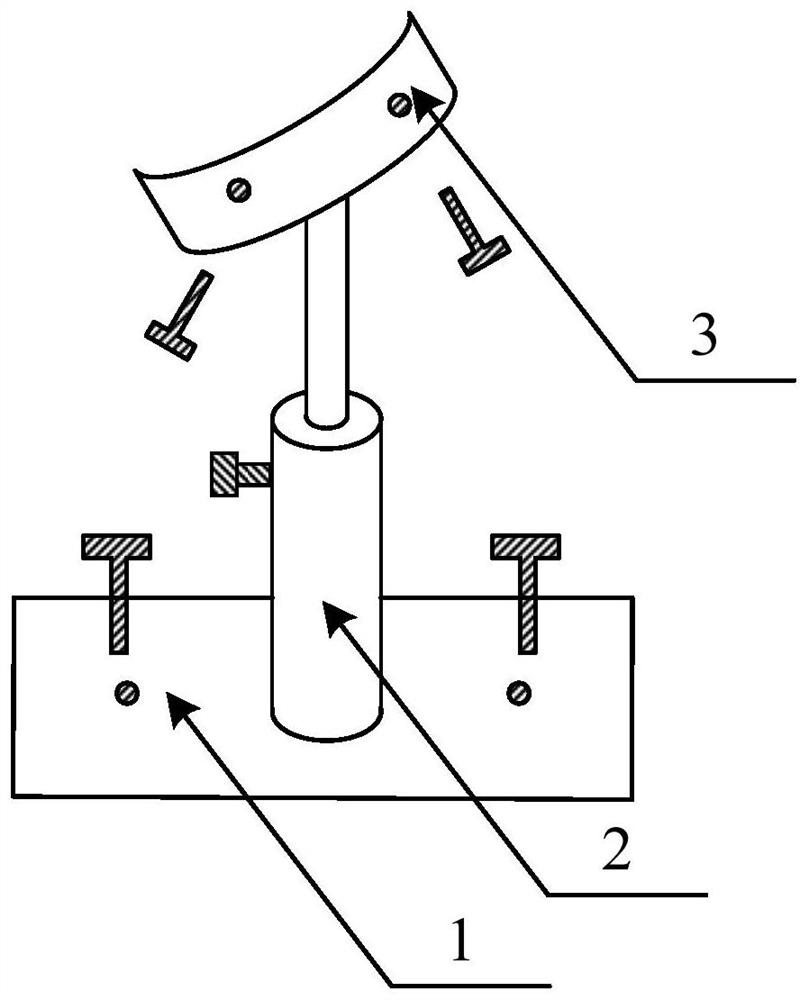

[0043] The separated Hopkinson compression bar experimental system is the ideal medium for the study of high strain rate (10 2 ~104 ) is the most important experimental method for the mechanical properties of materials, and is an important component in the experimental technology of explosion and impact dynamics. Aiming at the limitations of obtaining the lateral strain of the test piece by attaching strain gauges to the side of the test piece commonly used in the prior art, the present invention proposes a device and method for measuring the dynamic lateral strain of the test piece through liquid volume. The invention uses the expansion of the side volume of the test piece when it is subjected to dynamic impact, skillfully converts the change of the side volume of the test piece under dynamic load into the change of liquid volume, and then obtains the dynamic lateral volume of the test piece during the dynamic load process. strain parameter. Compared with the traditional met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com