Sealing method for reducing rejection rate of sealing of glass thermometer

A thermometer and scrap rate technology, applied in glass molding, glass reshaping, glass manufacturing equipment, etc., can solve the problems of reduced effective length of jacket, affecting product qualification rate, damage, etc., to reduce disposal and cleaning time, reduce The number of equipment adjustments and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment, further illustrate the present invention.

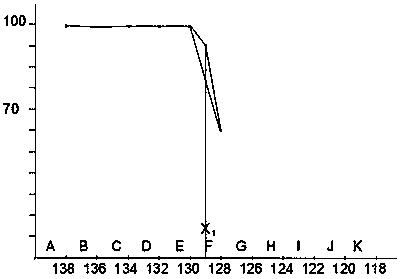

[0023] Explanation: the thermometer L of this embodiment is 140mm; the automatic sealing machine used in production is WTFK-01 type automatic sealing machine, and the above-mentioned sealing machine is a sealing machine independently developed by the company, and different sealing machines are determined according to the results of this method There may be differences in numerical values, but this method can determine the lower limit of the length with a higher sealing yield, and improve the sealing efficiency and yield.

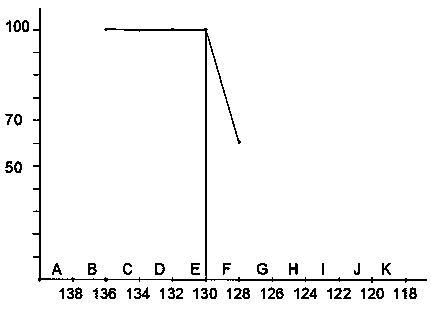

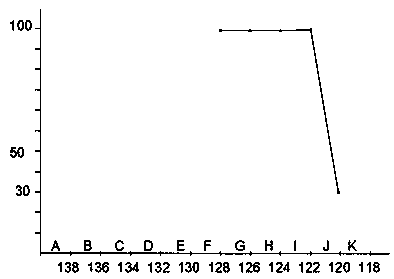

[0024] see Figure 1-Figure 4 As can be seen, a kind of sealing method that reduces glass thermometer sealing reject rate of the present invention comprises the following steps:

[0025] (1) Classify the glass shells of thermometers according to the length between the seal of the glass thermometer and the nearest edge of the shell. The length L of the glass shell with c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com