Hardware storing device

A storage device and hardware technology, applied in the storage field, can solve problems affecting the cleanliness of the workbench, delaying production progress, increasing production costs, etc., and achieve the effect of simple structure, preventing nuts from being lost and falling around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

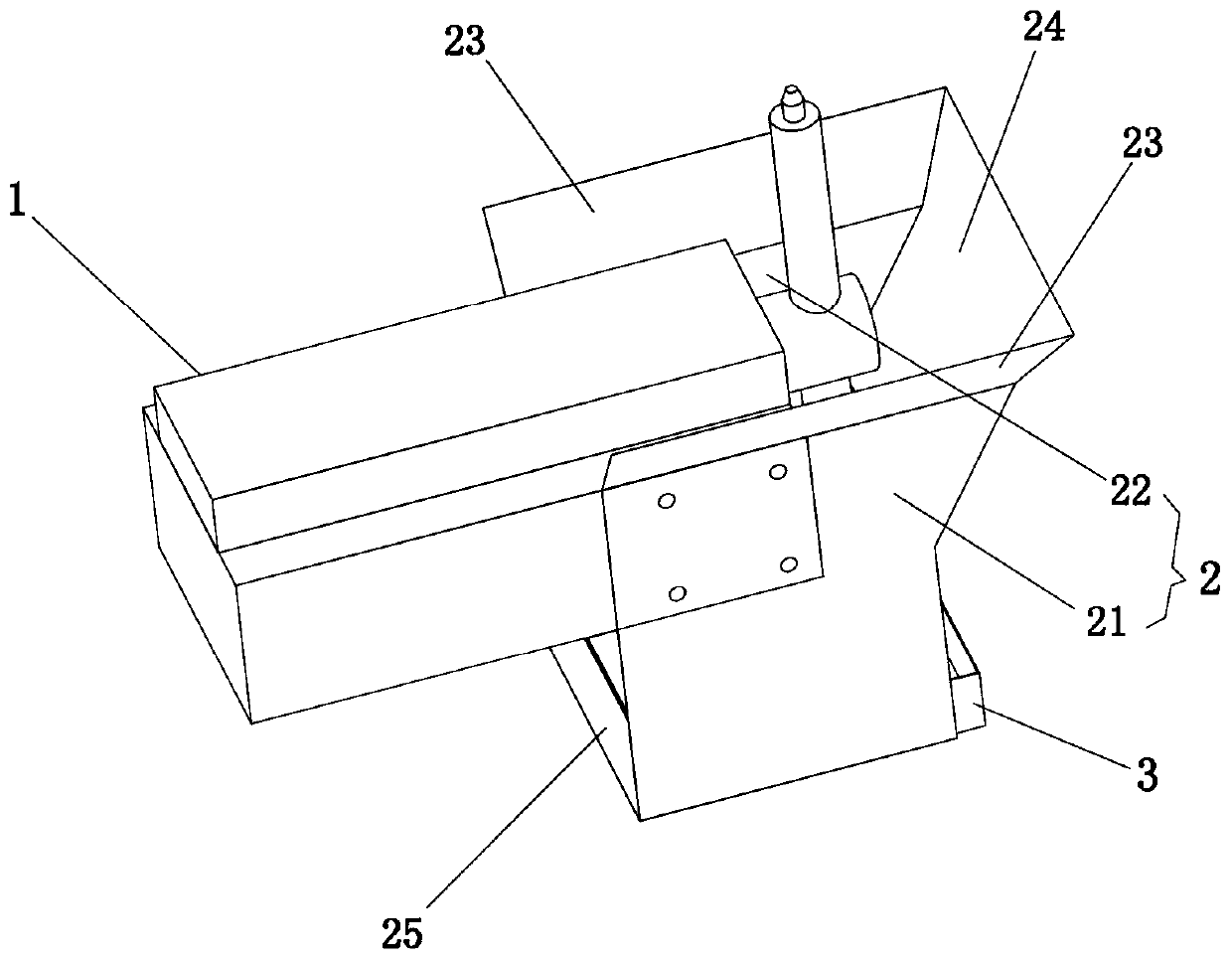

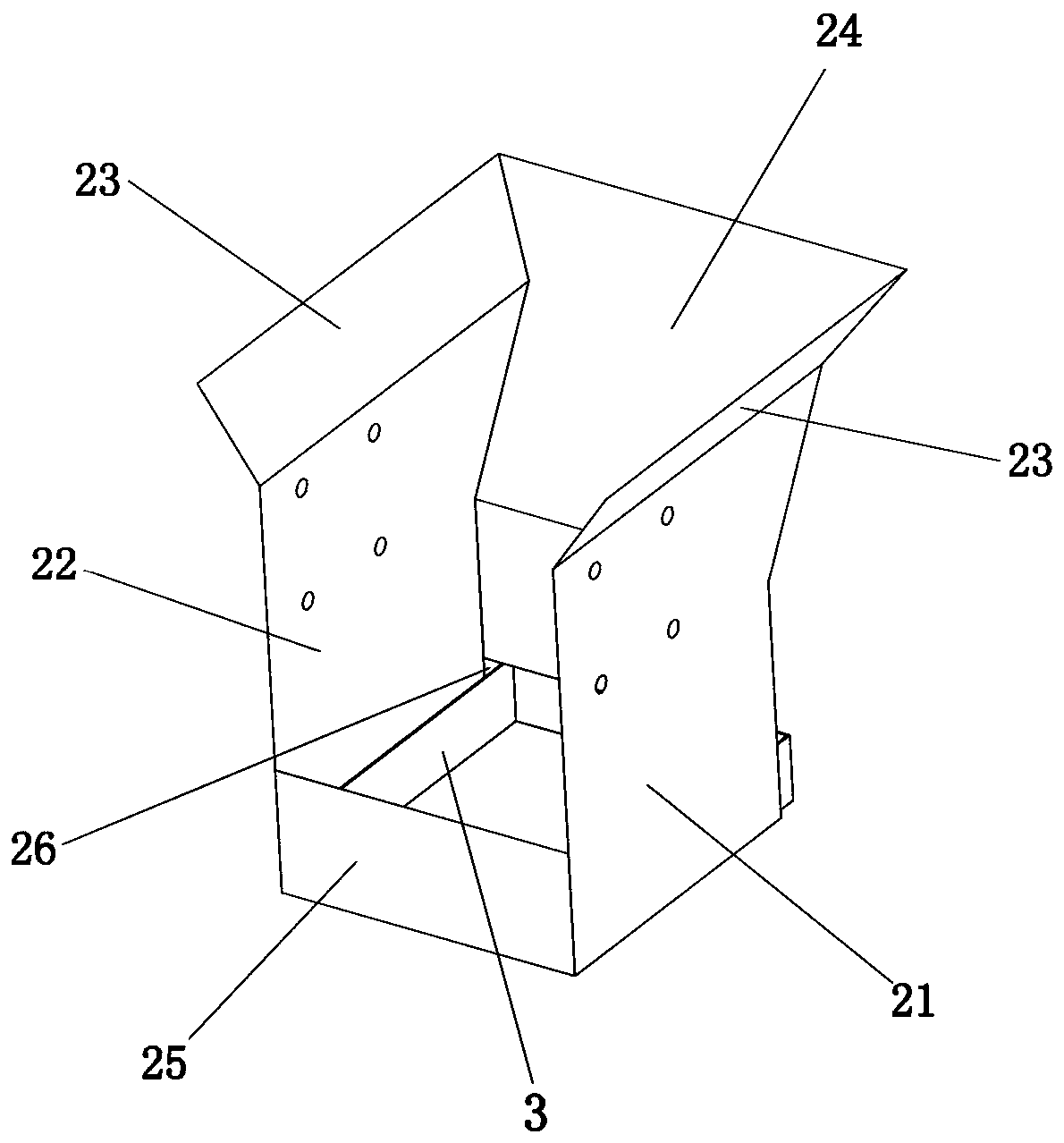

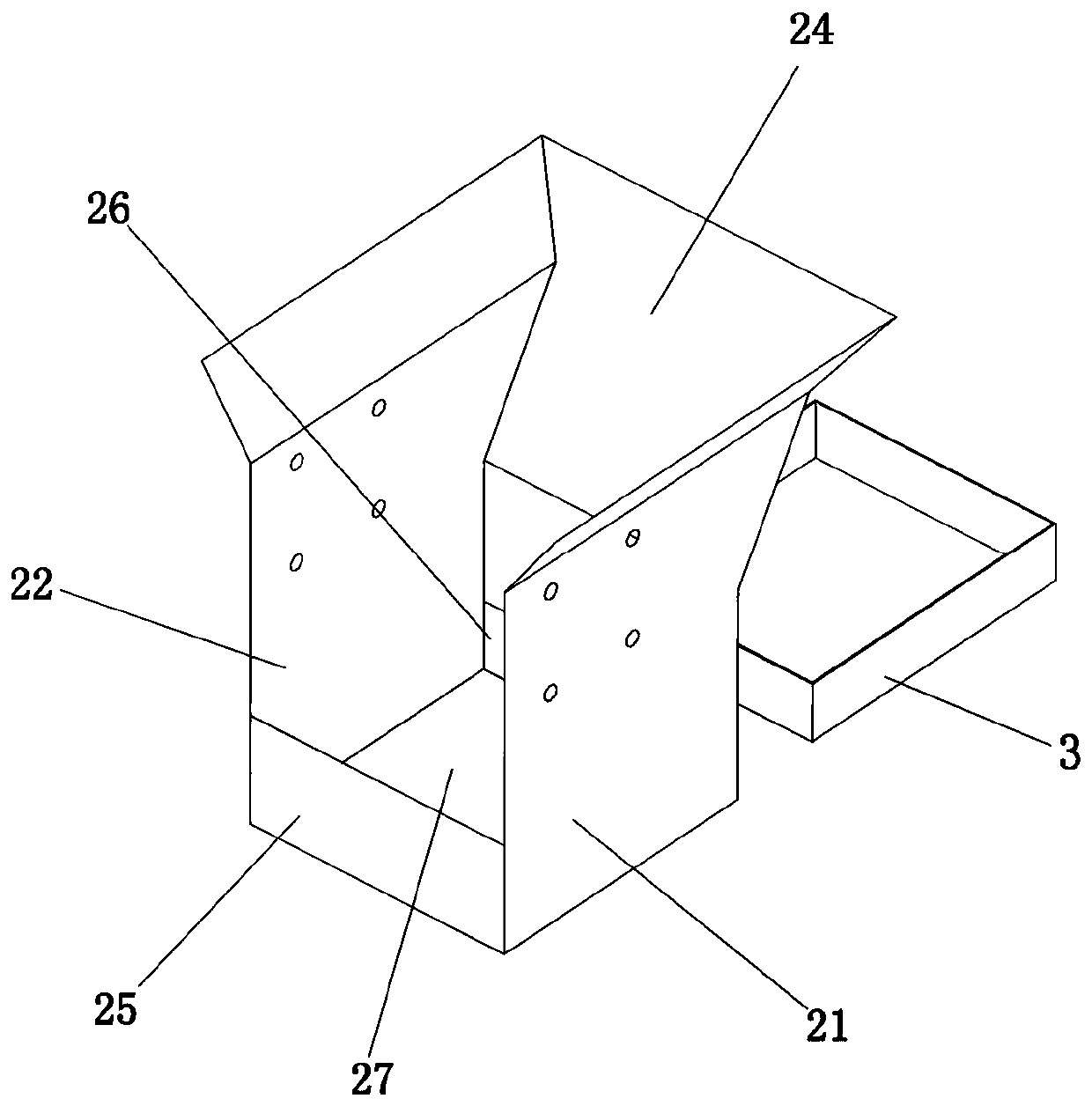

[0017] A storage device for hardware, such as figure 1 , figure 2 , image 3 As shown, it includes an introduction frame 2 that is used for nut introduction on the welding device 1, and the introduction frame 2 includes a front fixing plate 21 and a rear fixing plate 22 that are arranged on the front and rear sides of the welding device 1 end; The upper ends of the plate 21 and the rear fixing plate 22 are inclined outwards to form a guide plate 23 respectively; Imported into the lead-in frame 2, the right side between the front fixing plate 21 and the rear fixing plate 22 is respectively connected with a side guide plate 24, and the side guide plate 24 is positioned at the outer side of the end of the welding device 1, so that the welding device 1 Fittings such as nuts on the workbench are introduced into the lead-in frame 2; the left bottom between the front fixing plate 21 and the rear fixing plate 22 is connected with a left limiting plate 25; the bottom of the left lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com