Solder paste temperature return time control system

A time control system and solder paste technology, applied in the direction of tin feeding device, manufacturing tools, auxiliary devices, etc., can solve the problems of excessive temperature recovery, insufficient temperature recovery, and manual temperature recovery time of solder paste, so as to ensure the temperature recovery time , The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

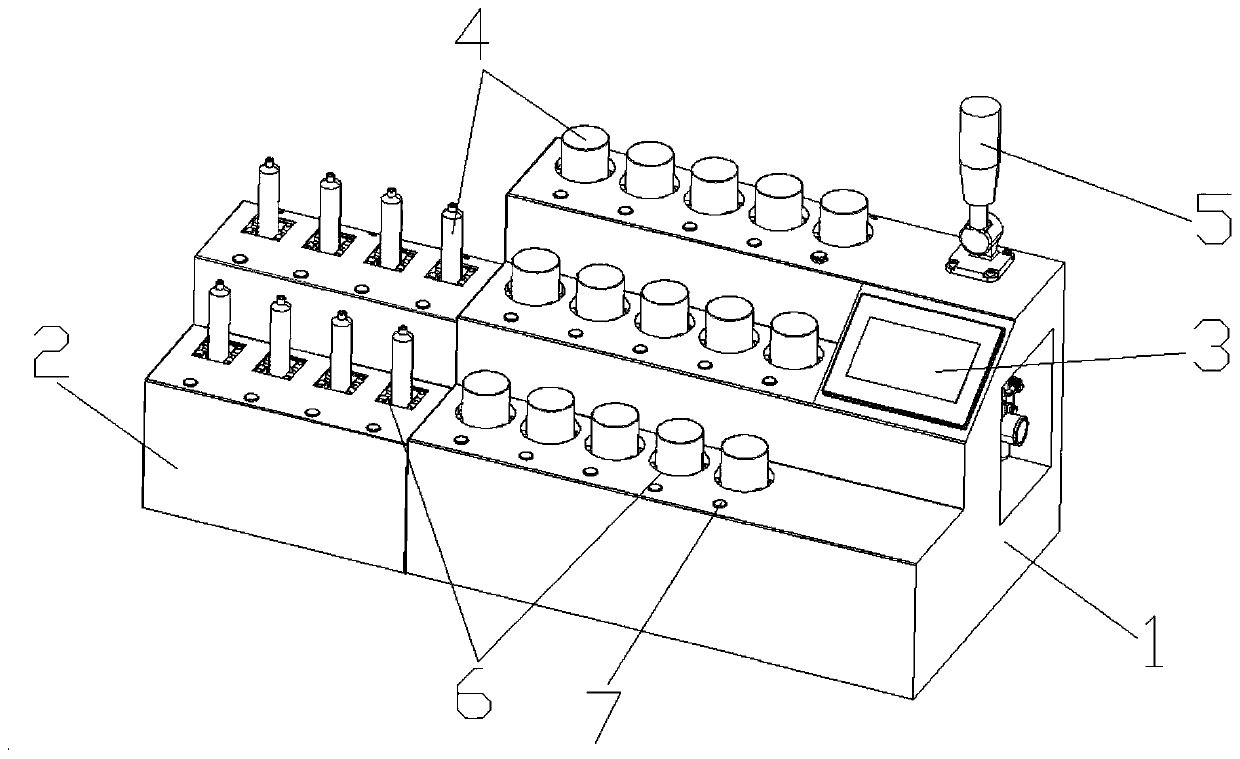

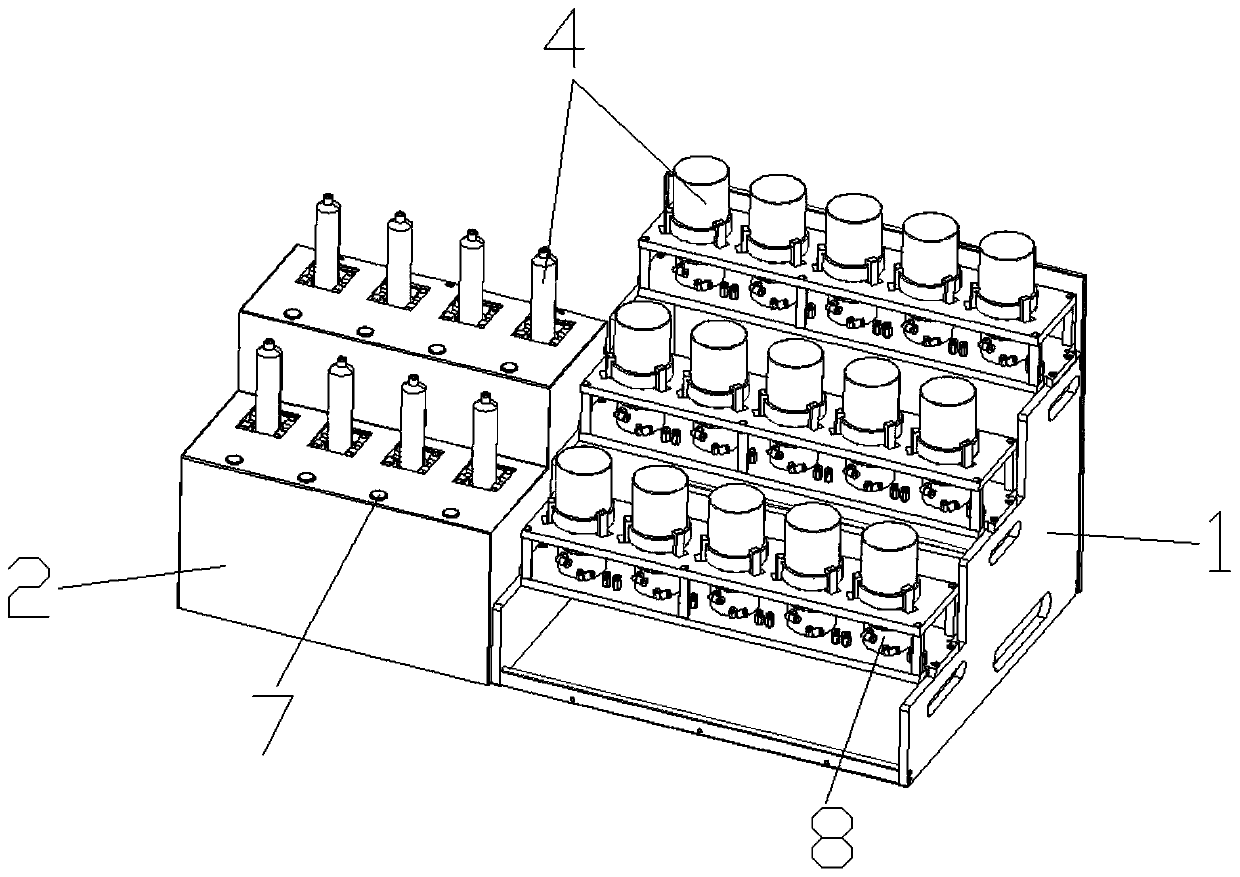

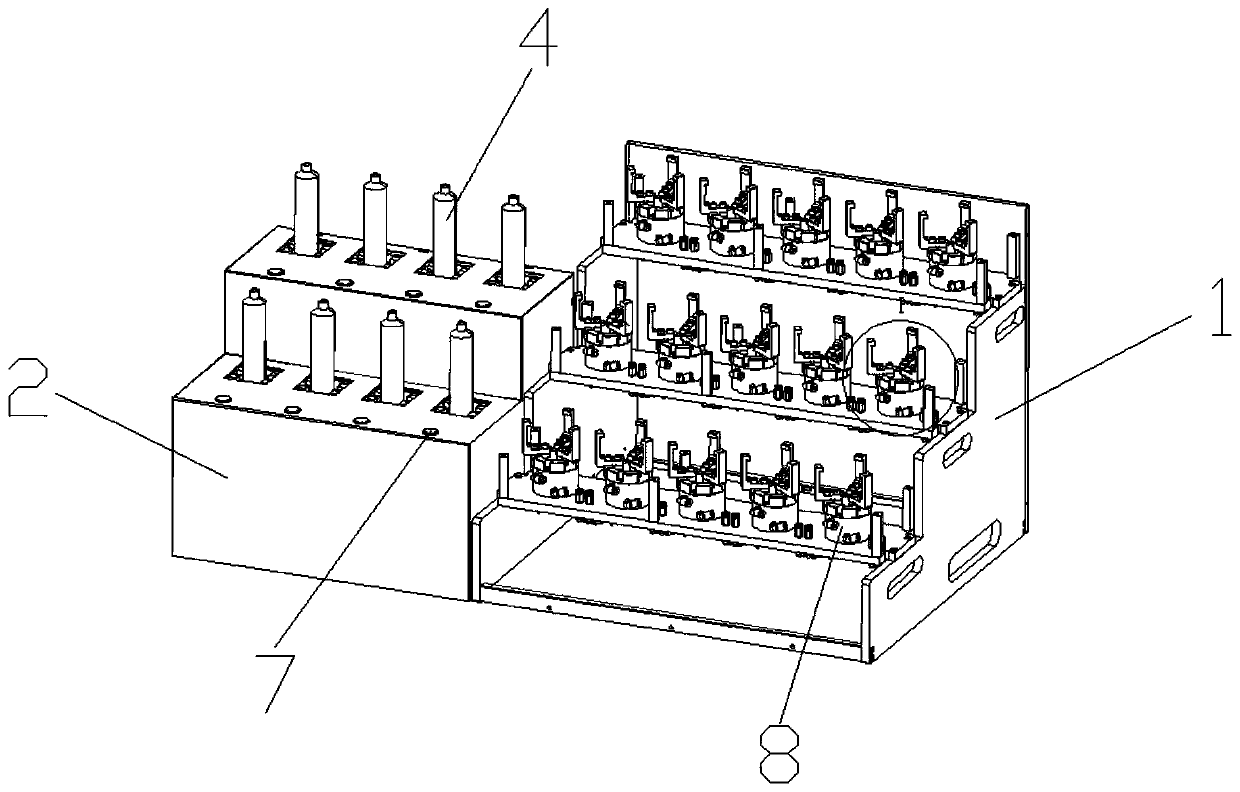

[0039] Firstly, the original intention of the design of the present invention is explained, because the current access management of solder paste is entirely controlled by manual control. This method is not only difficult to ensure the quality of solder paste, but also difficult to avoid the abuse or misuse of solder paste. In addition, the storage environment temperature and reheating time of solder paste are often controlled manually. It is inevitable that excessive or insufficient reheating will occur due to manual negligence or forgetting, resulting in poor quality of solder paste; moreover, relying on manual control It is also difficult to use the first-in-first-out method, which also increases the labor cost. Further, the current reheating device can only reheat the solder paste for one kind of solder paste and one reheating time, and cannot simultaneously reheat the solder paste. Multiple different types of solder pastes are reheated at the same time. The invention prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com