A Maintenance Effect Modeling Method Considering the Negative Effects of Maintenance

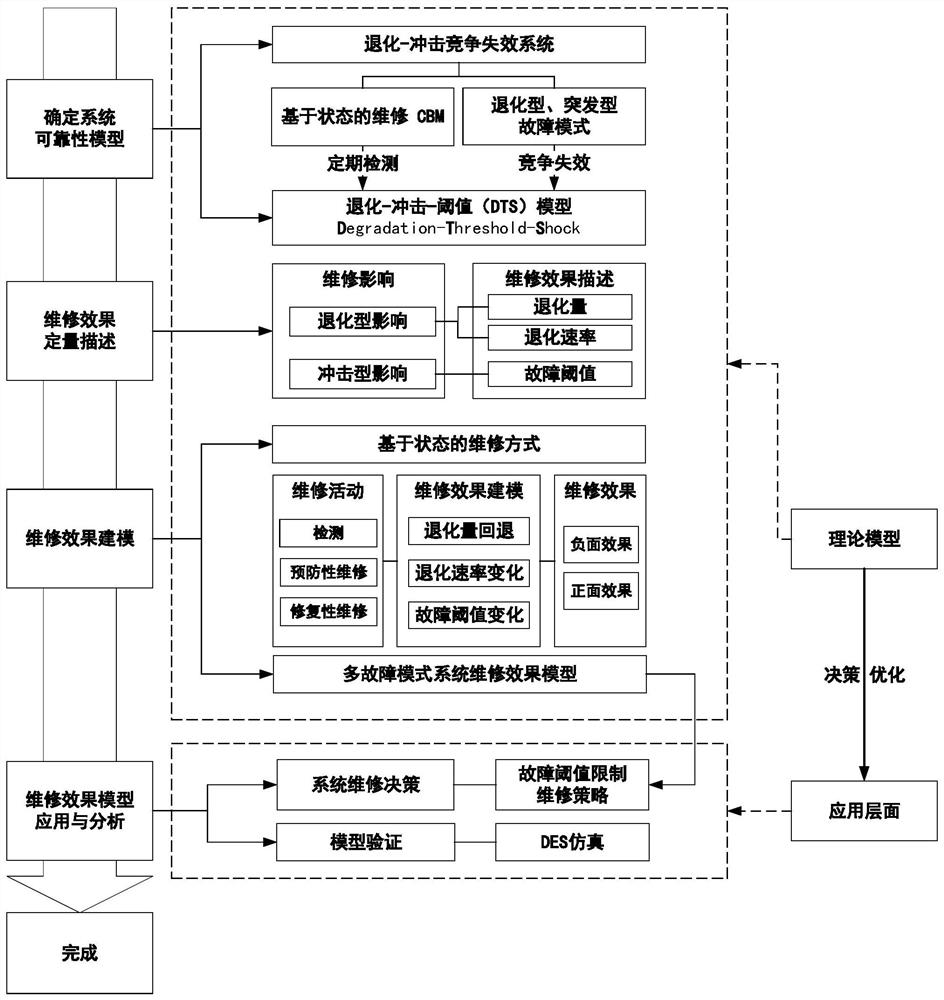

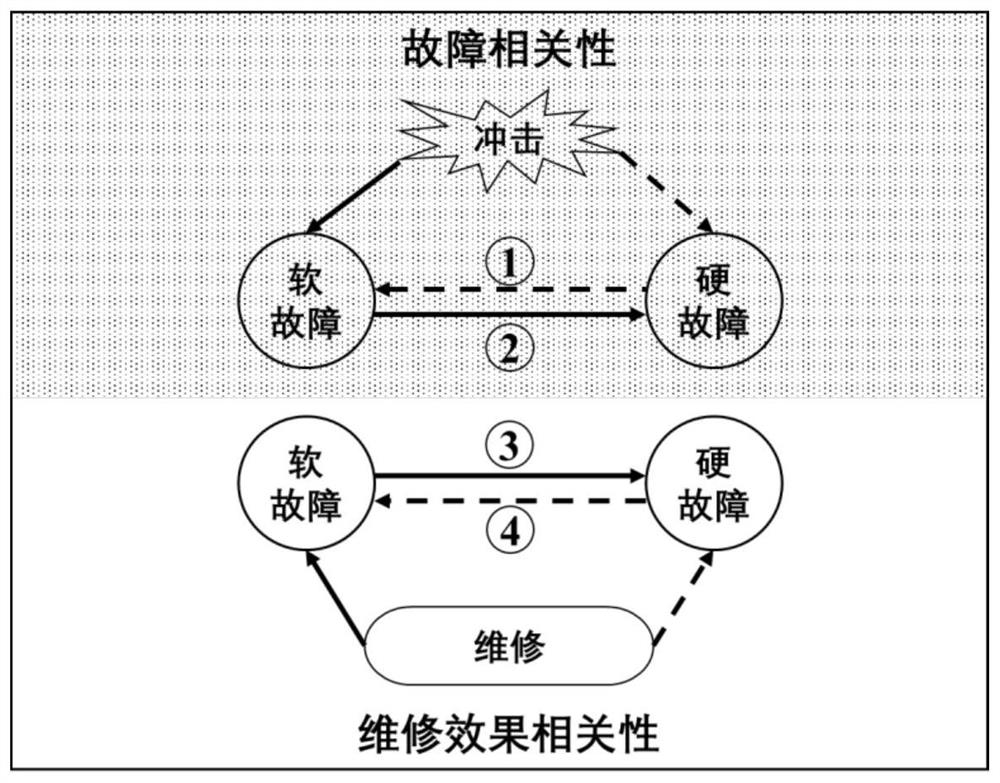

A modeling method and negative technology, applied in the direction of instrumentation, design optimization/simulation, calculation, etc., can solve problems such as harmfulness, catastrophe, product safety, reliability, performance, economy, maintainability, etc. Achieve the effect of reducing negative impact, achieving safety level, and enriching modeling forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

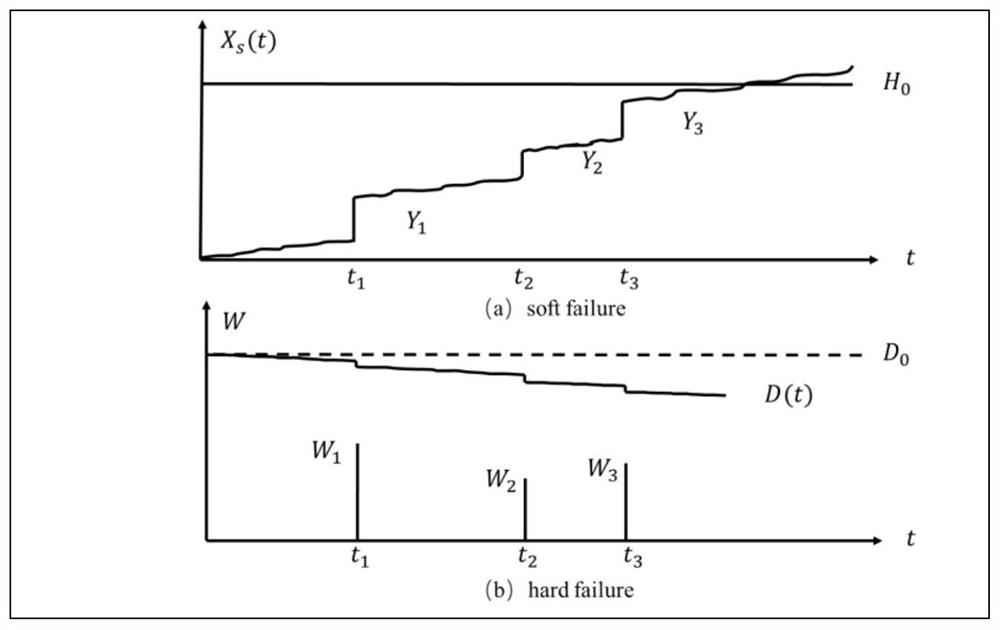

[0157] Taking a high-voltage transmission line system as an example, the system maintenance effect modeling is completed, and the application analysis is carried out.

[0158] The required parameters in the model are as follows:

[0159]

[0160] After the above steps 1, 2, and 3, the system maintenance effect model is established, and the reliability of the system can be obtained from the formula (4). In the above reliability function, for the reliability solution after multiple preventive maintenance before time t Because there are many kinds of convolutions, it is difficult to simplify. Therefore, this paper uses the Monte Carlo simulation method to solve the reliability of the system. The specific method is as follows Figure 7 .

[0161] Such as Figure 8 Shown is the reliability function of the system considering the maintenance effect. Among them, Case1 indicates that only the impact of preventive maintenance work on the degradation level is considered; Case2 cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com