Pressure sensor based on surface enhanced Raman scattering

A surface-enhanced Raman and pressure sensor technology, applied in the field of sensors, can solve the problems of large size, inability to provide electrical output, heavy mass, etc., and achieve high accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

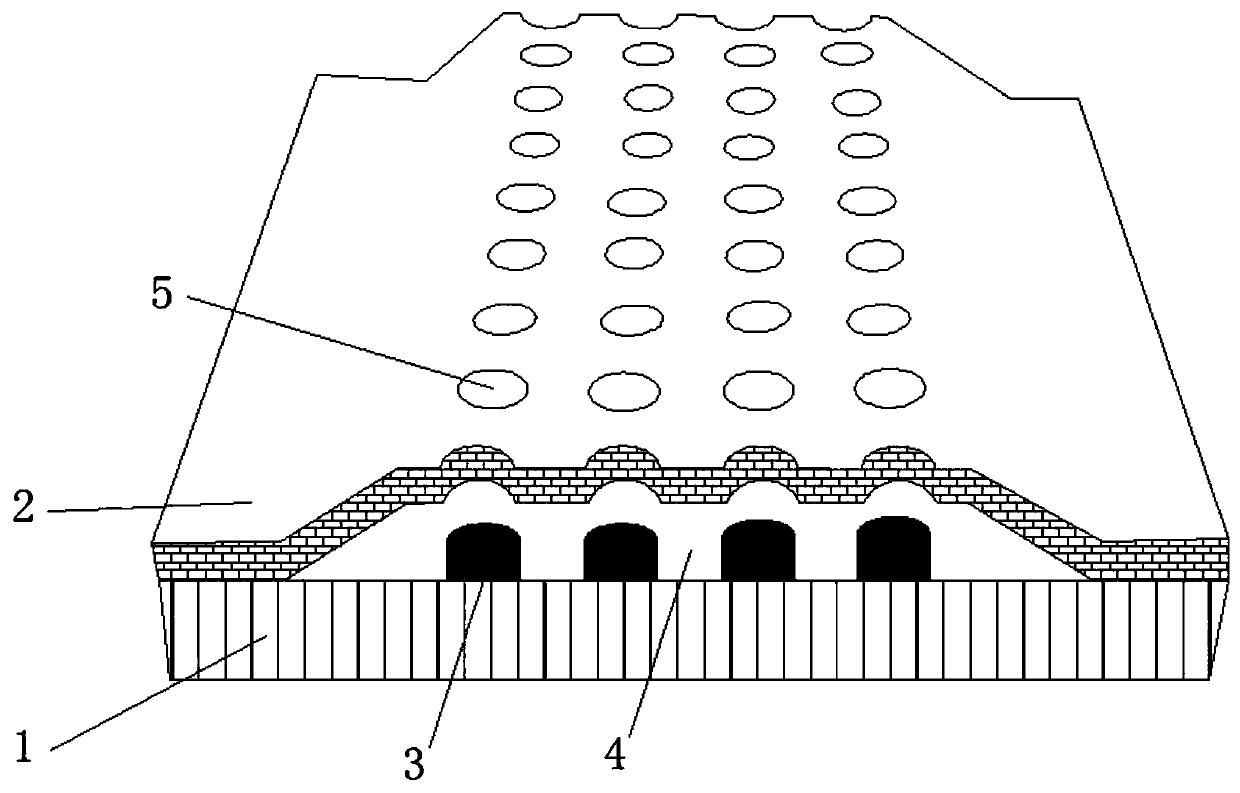

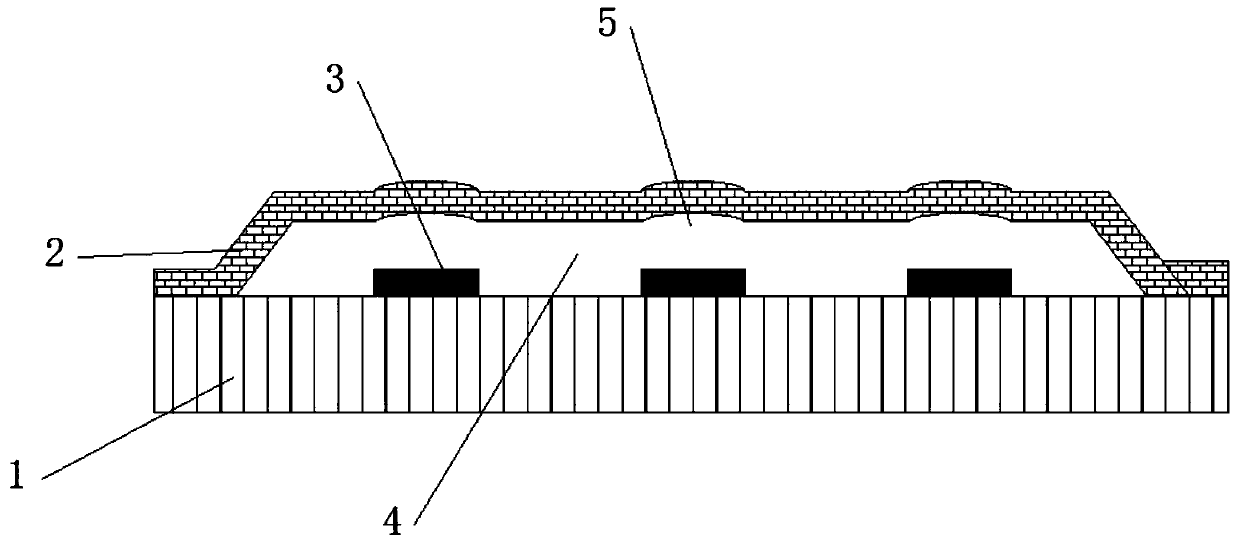

[0024] This embodiment provides a figure 1 The shown pressure sensor based on surface-enhanced Raman scattering includes a base layer 1, which mainly plays a supporting role and can transmit light. Therefore, the base layer 1 can be made of silicon dioxide; the base layer 1 A metal layer 2 is arranged above the base layer 1, and a cavity 4 is formed between the metal layer 2 and the base layer 1, specifically, as figure 2 , image 3 As shown, the cross section of the metal layer 2 is trapezoidal, the left and right sides are in contact with the base layer 1, and the middle part is not in contact with the base layer 1, so that a cavity 4 is formed between the metal layer 2 and the base layer 1; The metal layer 2 is also provided with periodically arranged holes 5, specifically, the holes 5 are located in the middle part of the metal layer 2, and the top of the base layer 1 is located at the vertical projection of the holes 5. The micro-nano metal particle layer 3 that is per...

Embodiment 2

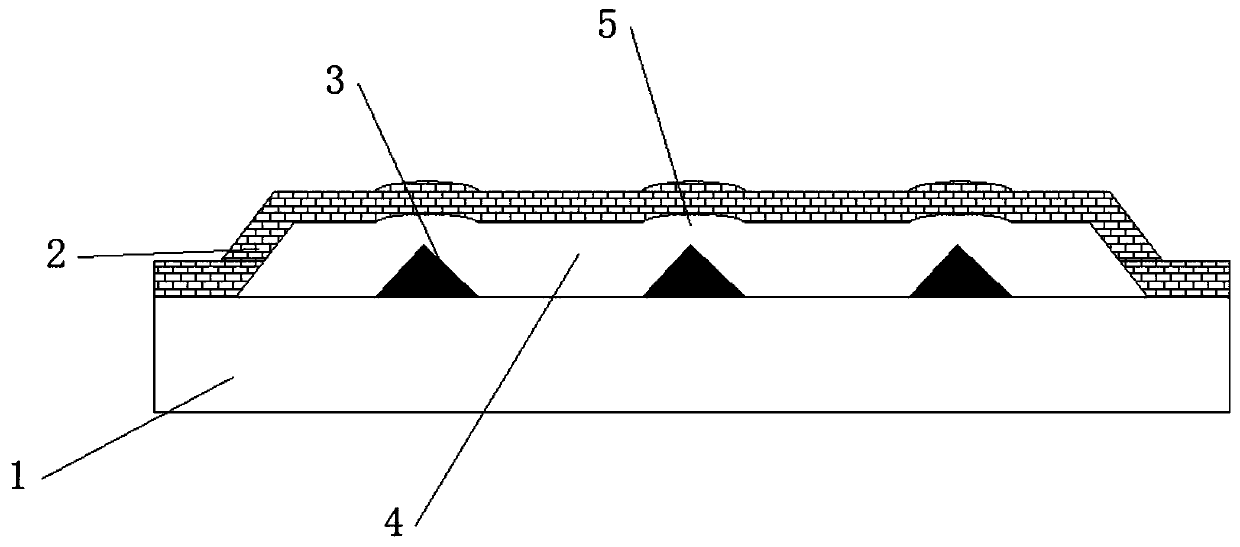

[0031] This embodiment provides a image 3 The shown pressure sensor based on surface-enhanced Raman scattering includes a base layer 1, which mainly plays a supporting role and can transmit light. Therefore, the base layer 1 can be made of silicon dioxide; the base layer 1 A metal layer 2 is arranged above the base layer 1, and a cavity 4 is formed between the metal layer 2 and the base layer 1, specifically, as image 3 As shown, the cross section of the metal layer 2 is trapezoidal, the left and right sides are in contact with the base layer 1, and the middle part is not in contact with the base layer 1, so that a cavity 4 is formed between the metal layer 2 and the base layer 1; The metal layer 2 is also provided with periodically arranged holes 5, specifically, the holes 5 are located in the middle part of the metal layer 2, and the top of the base layer 1 is located at the vertical projection of the holes 5. The micro-nano metal particle layer 3 in a permanent arrangeme...

Embodiment 3

[0038] On the basis of Example 1, such as Figure 4 As shown, the hole 5 is a triangular hole; the shape of the micro-nano metal particle layer 3 projected vertically in the hole 5 is a triangular column, which is conducive to the accumulation of large charges in the hole 5 and the micro-nano metal particle layer 3. On the tip of the triangle, the localized intensity of the electric field is greater, and the measurement accuracy is higher.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com