Wine freezing heat preservation tank with homogenizing function

A wine and heat preservation tank technology, applied in the field of wine brewing, can solve the problems of high transportation costs, increased logistics costs, inability to ensure ambient temperature, etc., and achieves the effect of maintaining stable temperature and avoiding contact with air to oxidize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

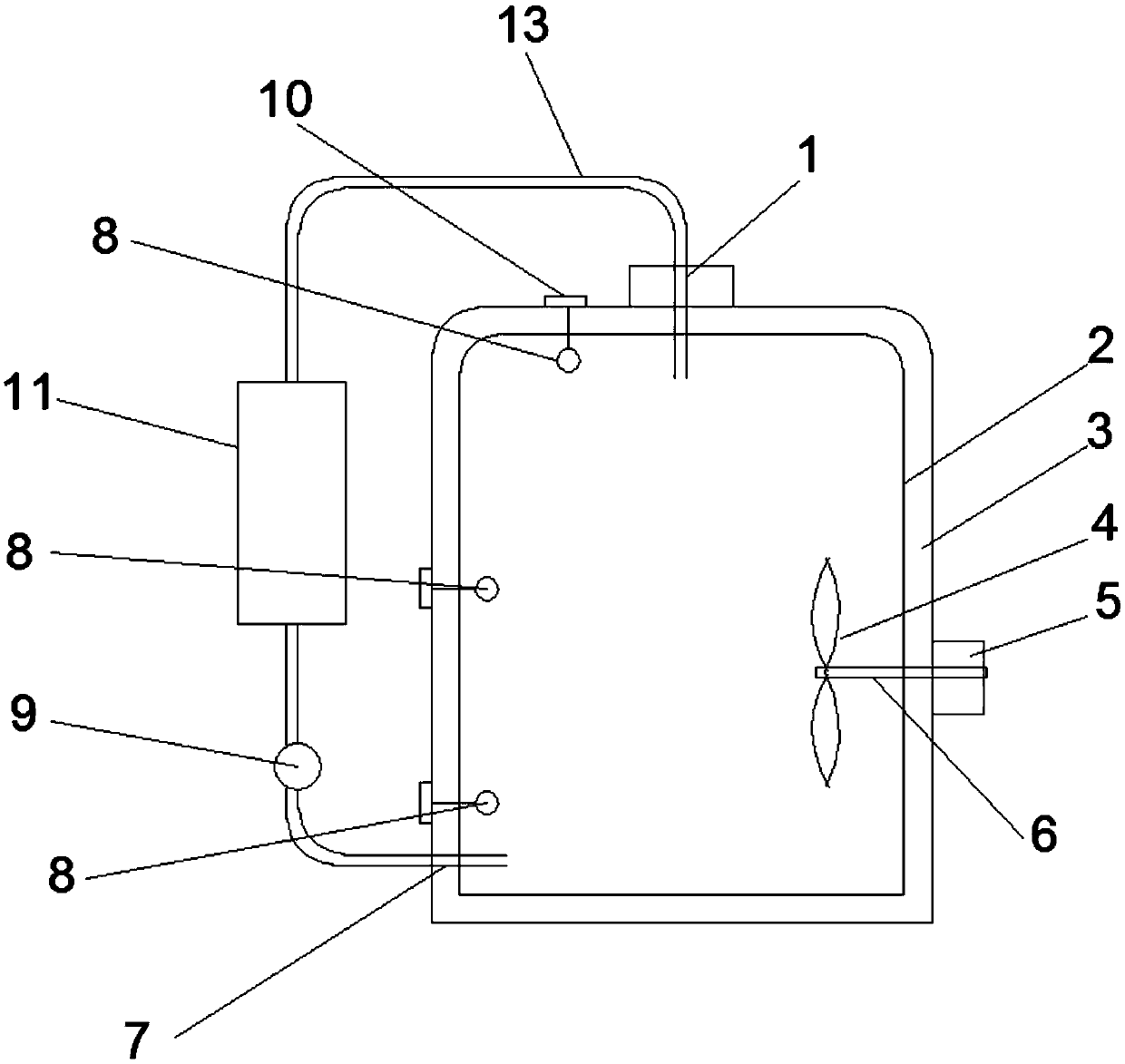

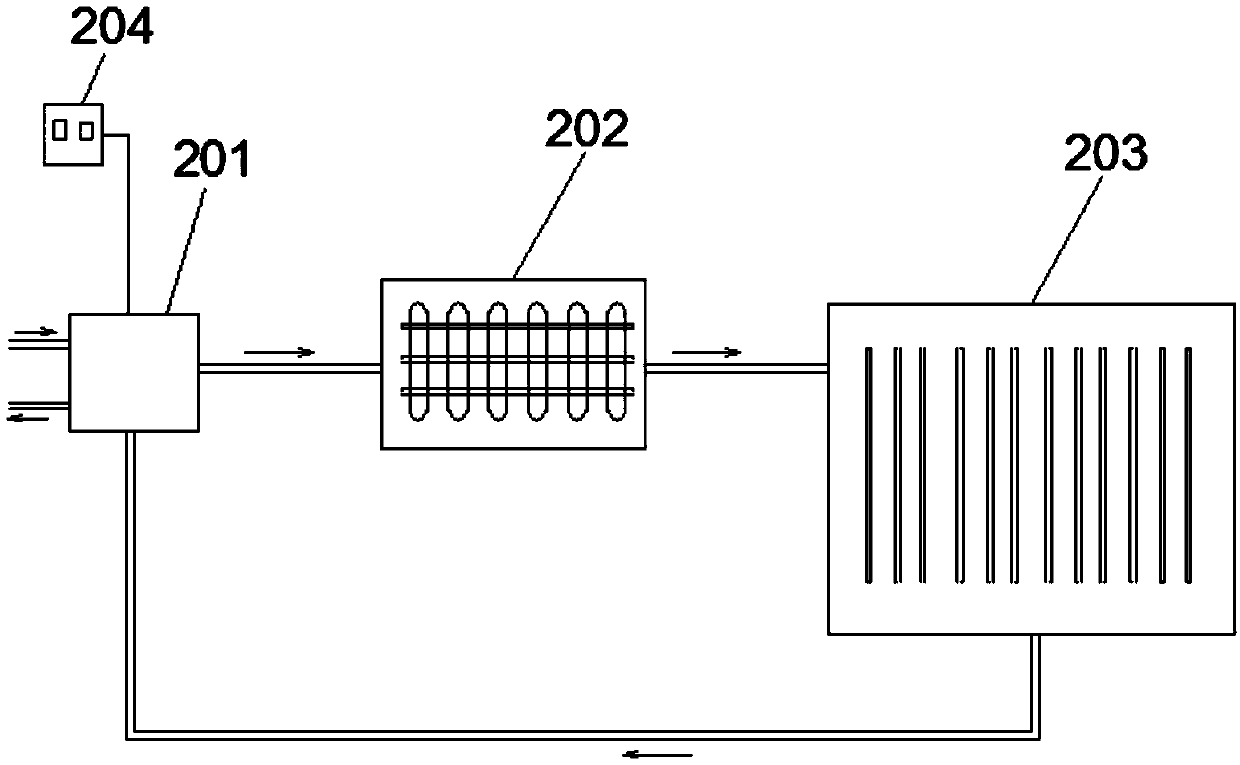

[0017] The technical scheme adopted in the present invention: as Figures 1 to 2 As shown, a wine freezing insulation tank with a homogeneous function includes a tank body 2, a refrigerator 11, a circulation pipeline 13, a centrifugal pump 9 and an agitator, and the outer coating of the tank body 2 is made of thermal insulation material Layer 3, the top of the tank body 2 is provided with a wine inlet 1, the bottom of the tank body 2 is provided with a wine outlet 7, one end of the circulation pipe 13 is connected to the wine inlet 1, and the other end of the circulation pipe 13 is connected to The wine outlet 7 and the circulating pipeline 13 are provided with a centrifugal pump 9 and a refrigerator 11 along the direction from the wine inlet 1 to the wine outlet 7. The agitator includes a stirring blade 4, a blade shaft 6 and a driving motor 5, and the stirring blade 4 Set in the middle area inside the tank body 2, the stirring blade 4 is set on the impeller shaft 6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com