Residue and water anti-blocking device of garbage disposer

A technology of garbage disposal and slag water, applied in water supply installations, indoor sanitary pipe installations, buildings, etc., can solve problems such as reducing the possibility of blockage of urban sewers, improve anti-blocking and anti-backflow performance, avoid resource waste, The effect of preventing clogging and backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

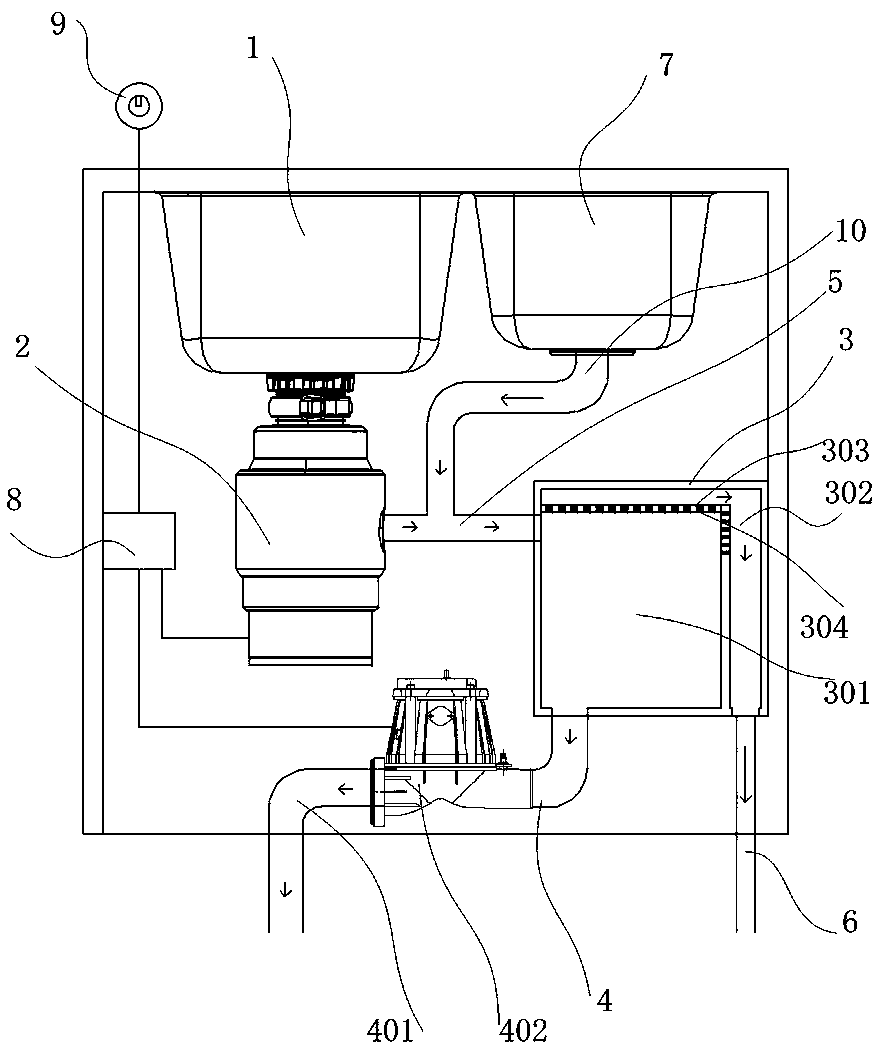

[0016] Embodiment 1: A slag water anti-clogging device for a garbage disposer, including a garbage discharge tank 1, a garbage disposer 2, a slag water anti-clogging device 3, and a vacuum slag discharge assembly 4. A garbage disposer is provided at the bottom of the garbage discharge tank 1 2 and connected with it, one end of the garbage disposer 2 is connected with a slag discharge pipe 5, the other end of the slag discharge pipe 5 is connected with the slag water anti-blocking device 3, and one end of the slag water anti-blockage device 3 is connected with the vacuum discharge The slag assembly 4 components are connected, and its other end is connected with the sewage discharge pipeline 6. The sewage discharge tank 7 is installed at the side end of the garbage discharge tank 1, and the sewage discharge tank 7 is connected to the slag discharge pipe 5 through the connecting pipeline 10. connected.

Embodiment 2

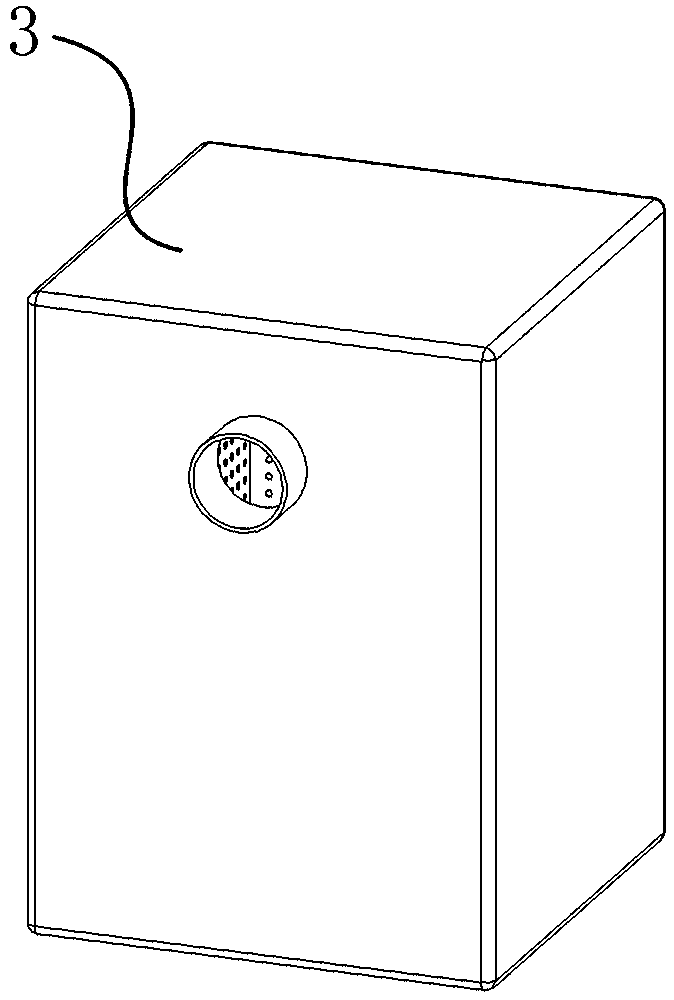

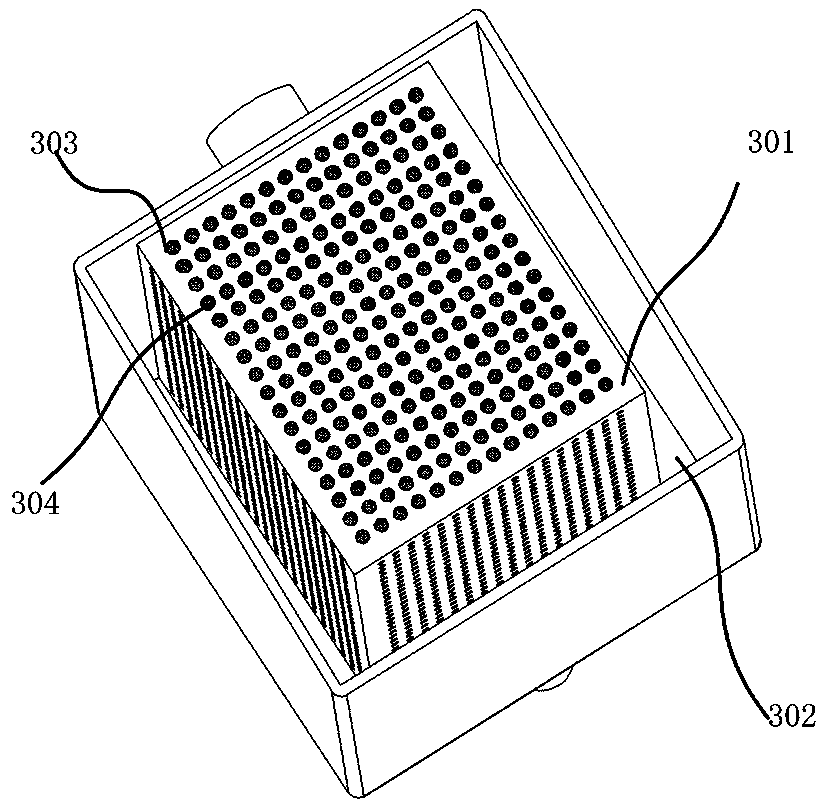

[0017] Embodiment 2: The slag water anti-blockage device 3 is in a cabinet structure, and the slag water anti-blockage device 3 is provided with two parts, one of which is a slag storage tank 301, and one end of the slag storage tank 301 is connected to the slag discharge pipe 5 Through, overflow holes 303 are distributed on the slag storage tank 301, and a filter screen 304 is fixedly installed in the overflow holes 303, and the other part of the slag water anti-blocking device 3 is an overflow tank 302, and the overflow tank 302 One end is connected with sewage discharge pipe 6.

Embodiment 3

[0018] Embodiment 3: The vacuum slag discharge assembly 4 includes a vacuum slag discharge pipeline 401 and a vacuum valve 402, one end of the vacuum slag discharge pipeline 401 is connected to the slag storage tank 301, and the vacuum valve 402 is installed on the vacuum slag discharge pipeline 401 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com