Integrally poured building house construction device and construction method thereof

A construction device and house technology, applied in construction, protection devices, excavation, etc., can solve problems such as erosion of concrete foundation, prolonging construction time, affecting foundation quality, etc., to reduce erosion, ensure construction quality, and shorten maintenance time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

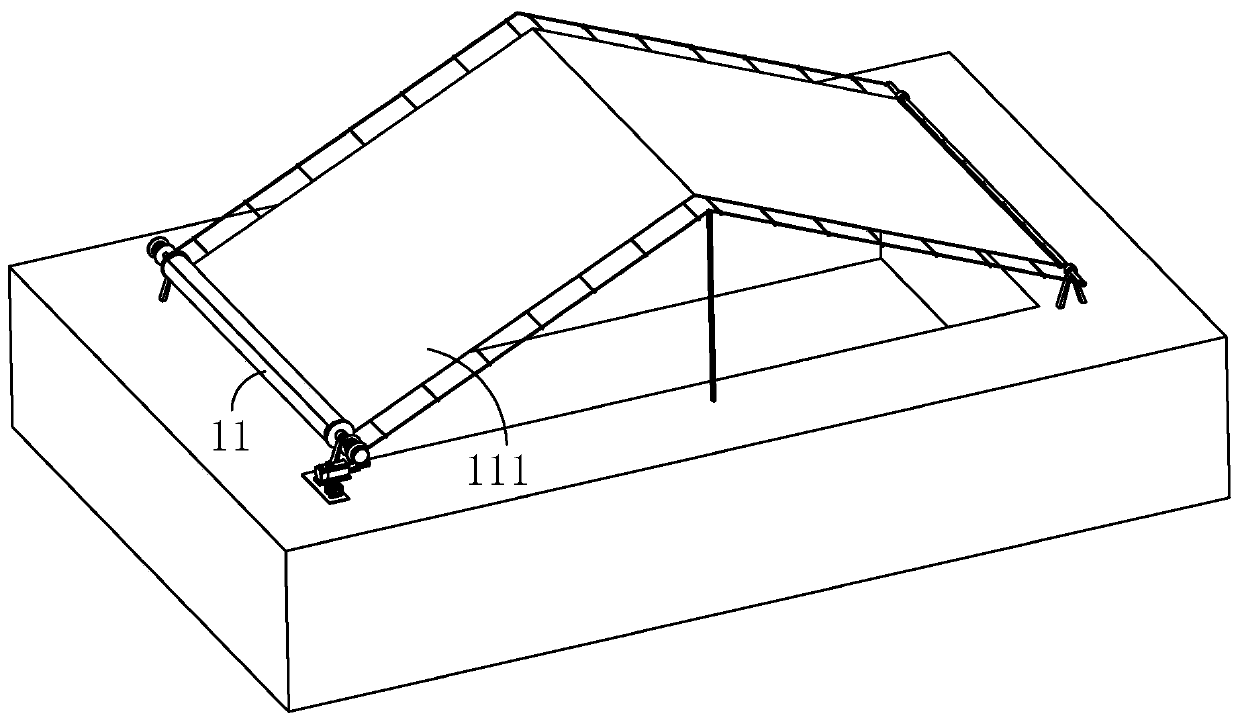

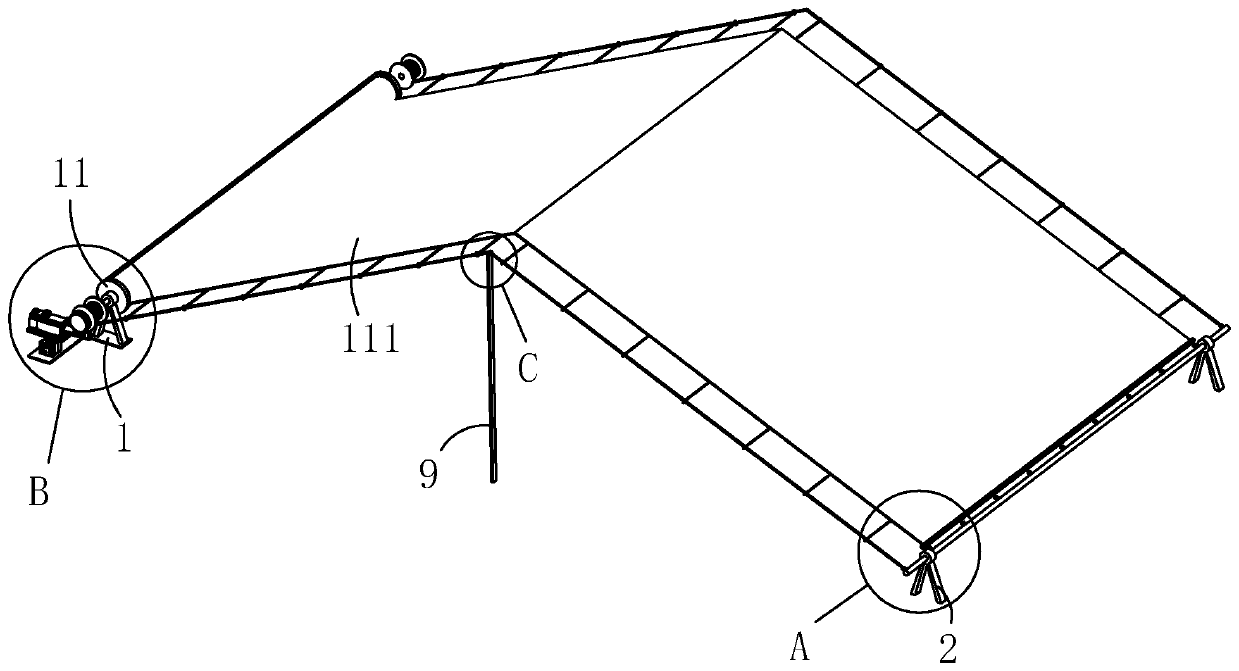

[0043] Such as figure 1 , 2As shown, an integrated pouring building construction device includes a frame 1 and a positioning frame 2. A winding roller 11 is rotated on the frame 1, and a rain-shielding curtain 111 is wound around the winding roller 11 to cover the rain. The curtain 111 can be made of polyethylene or polypropylene.

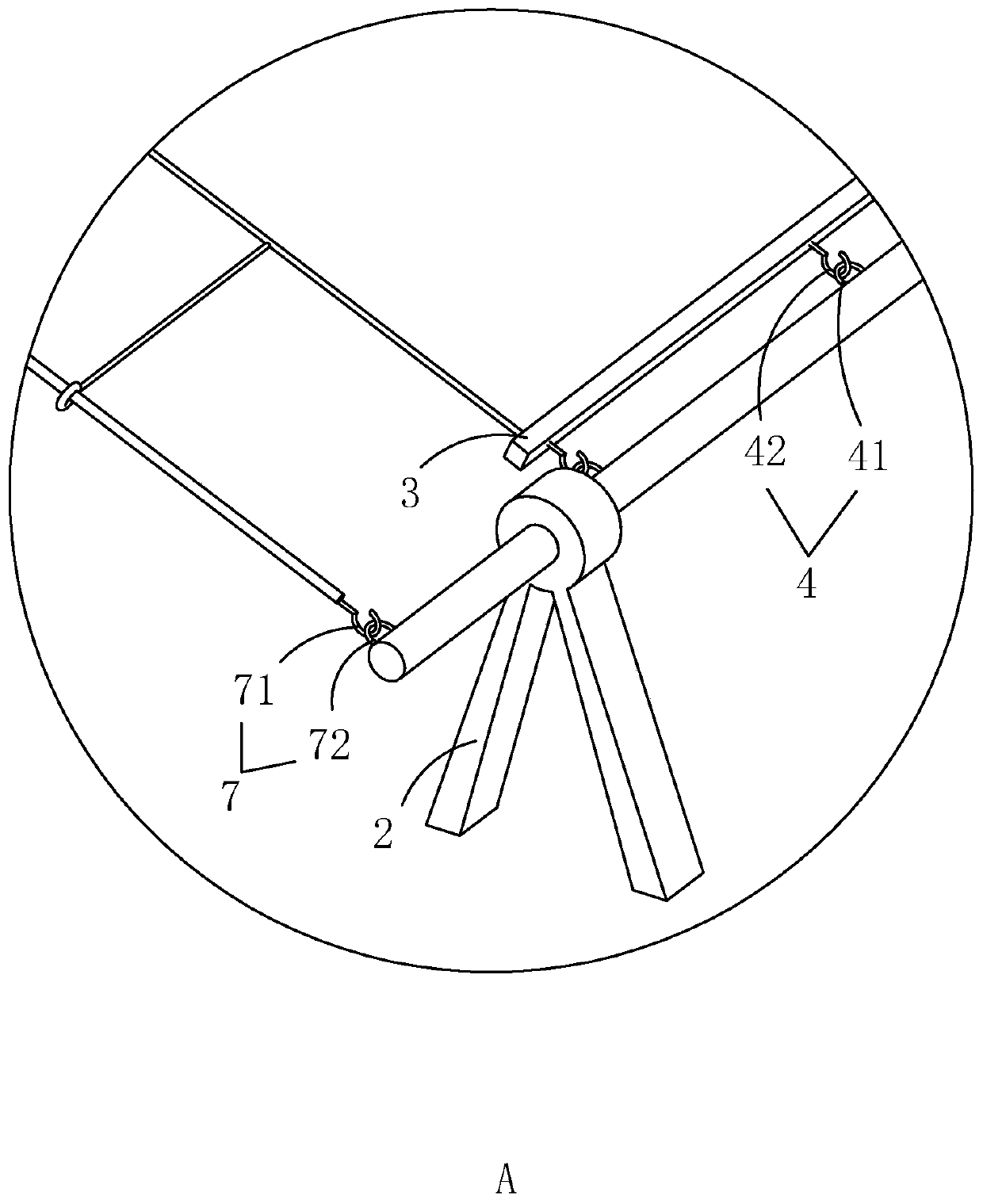

[0044] Such as figure 2 , 3 As shown, the movable end of the rain screen 111 is fixedly provided with a positioning rod 3 along the axial direction of the winding roller 11, and the movable end of the rain screen 111 is the end away from the frame 1 when the rain screen 111 covers the foundation.

[0045] Such as figure 2 , 3 As shown, the positioning frame 2 and the positioning rod 3 are provided with a first fixing assembly 4 for fixing the position of the positioning rod 3. The first fixing assembly 4 is provided with at least two groups. The first fixing assembly 4 includes a first hanging ring 41 and a first The hook 42 and the first h...

Embodiment 2

[0057] An integrated pouring building construction method, comprising the following steps:

[0058] S1. Foundation treatment: clean up the floating sand and silt in the site, use excavators and loaders to carry out mechanical excavation and leveling, and then level it manually and compact it with a road roller to form a foundation pit, waiting for pouring concrete.

[0059] S2. Pouring concrete, constructing a foundation reinforcement cage, and pouring concrete to form foundation piles. After mass concrete is poured, moisture retention and temperature control measures should be taken within 10-12 hours. The temperature difference between the inside and outside of the concrete should not be greater than 25°C, and the temperature difference between the surface of the concrete pouring body and the atmosphere should not be greater than 20°C. In 15-20d.

[0060] S3, Drainage open ditch treatment, set up a drainage ditch on both sides of the foundation to ensure smooth drainage.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com