Construction method of underground continuous wall with water-rich karst development geology and grouting wall structure

An underground diaphragm wall and construction method technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve problems such as collapsed holes and affect the quality of groove formation, and achieve the effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

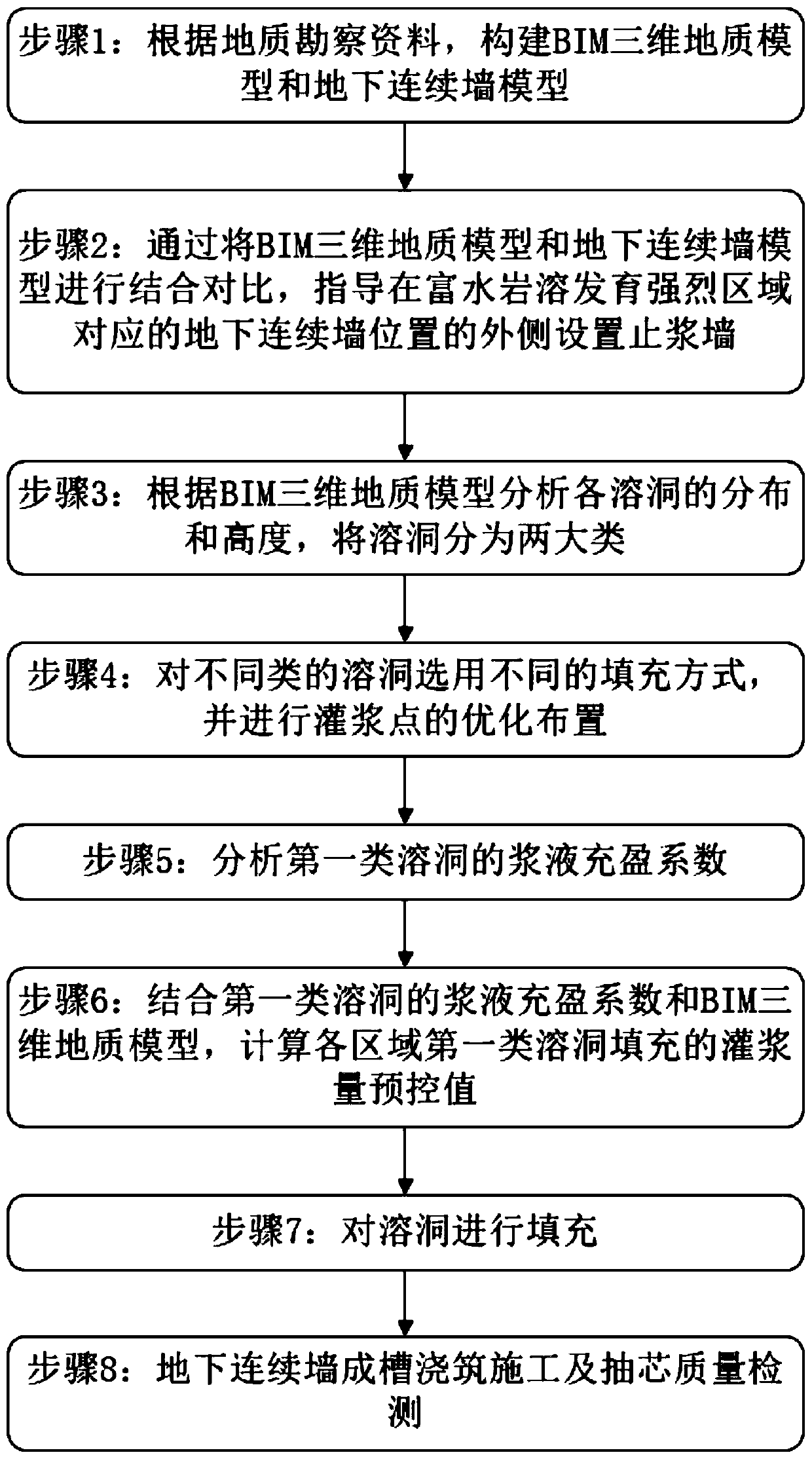

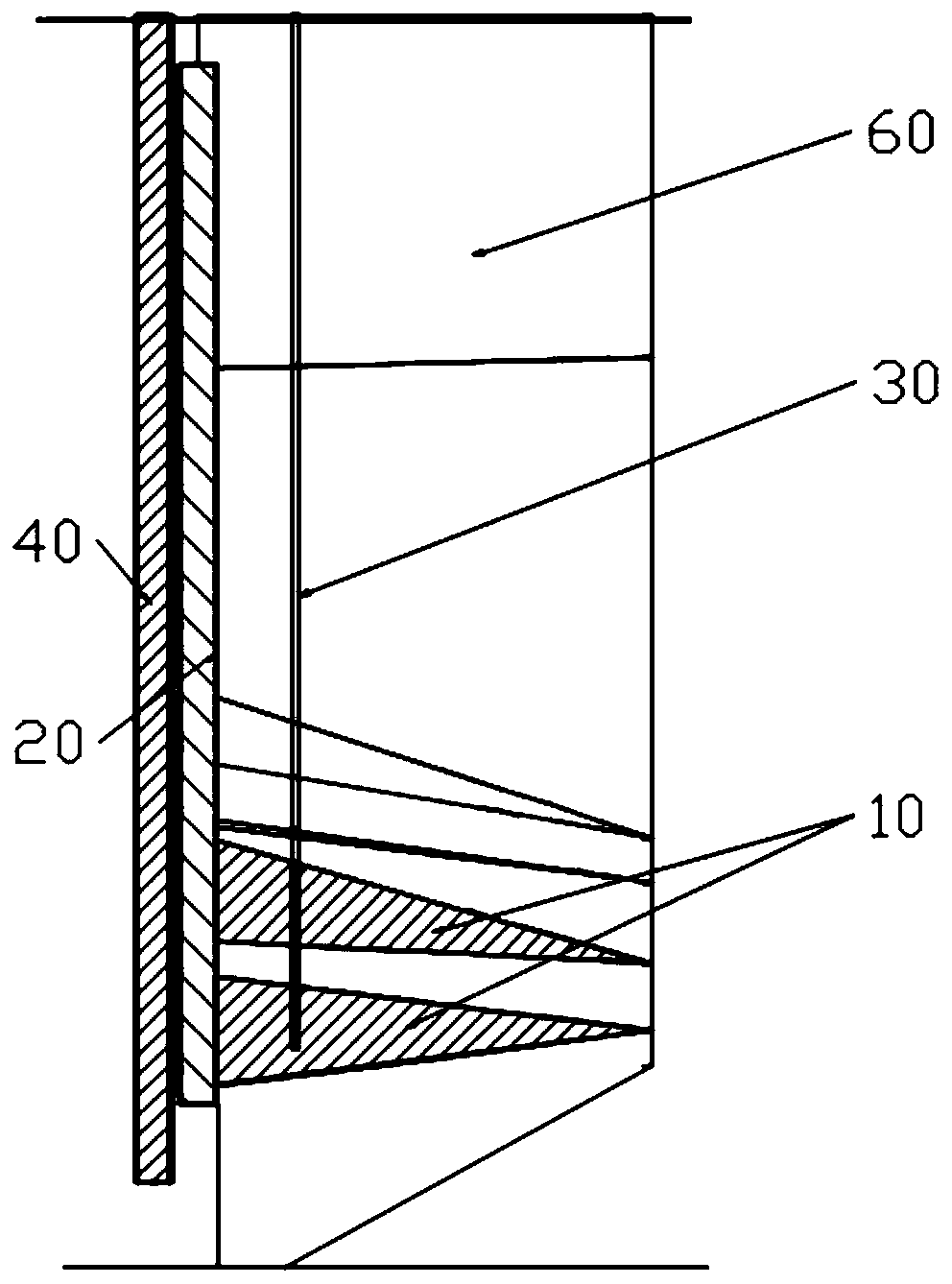

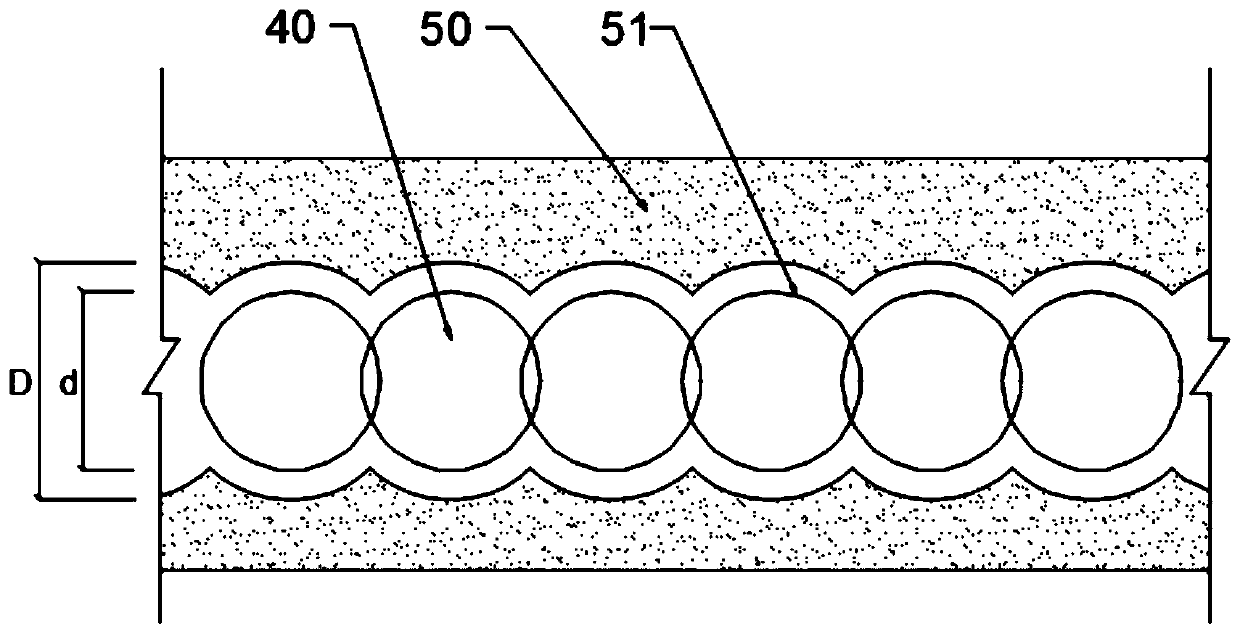

[0045] see Figure 1 to Figure 5 The construction method of the underground diaphragm wall of the water-rich karst development geology of the present embodiment comprises the following steps,

[0046] Step 1: According to the geological survey data, carry out intensive supplementary reconnaissance in the area where the karst development of the underground diaphragm wall is relatively strong, and construct the BIM three-dimensional geological model and the proposed underground diaphragm wall 20 model;

[0047] Specifically, under the geological condition of water-rich karst, the intensified reconnaissance shall be carried out within 10m on both sides of the proposed underground diaphragm wall area, and the average distance between the survey holes shall not exceed 5m; 10m; outside the range of 25m, the average distance between survey holes shall not exceed 15m;

[0048] Furthermore, according to the distribution of the survey holes, they are grouped, and the plane position of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com