Automatic point drilling machine with loader and unloader

An automatic and drilling machine technology, which is applied to the crafts, conveyors, decorative arts, etc. used to produce decorative surface effects, can solve the problems of low production efficiency, low efficiency, labor and material resources, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

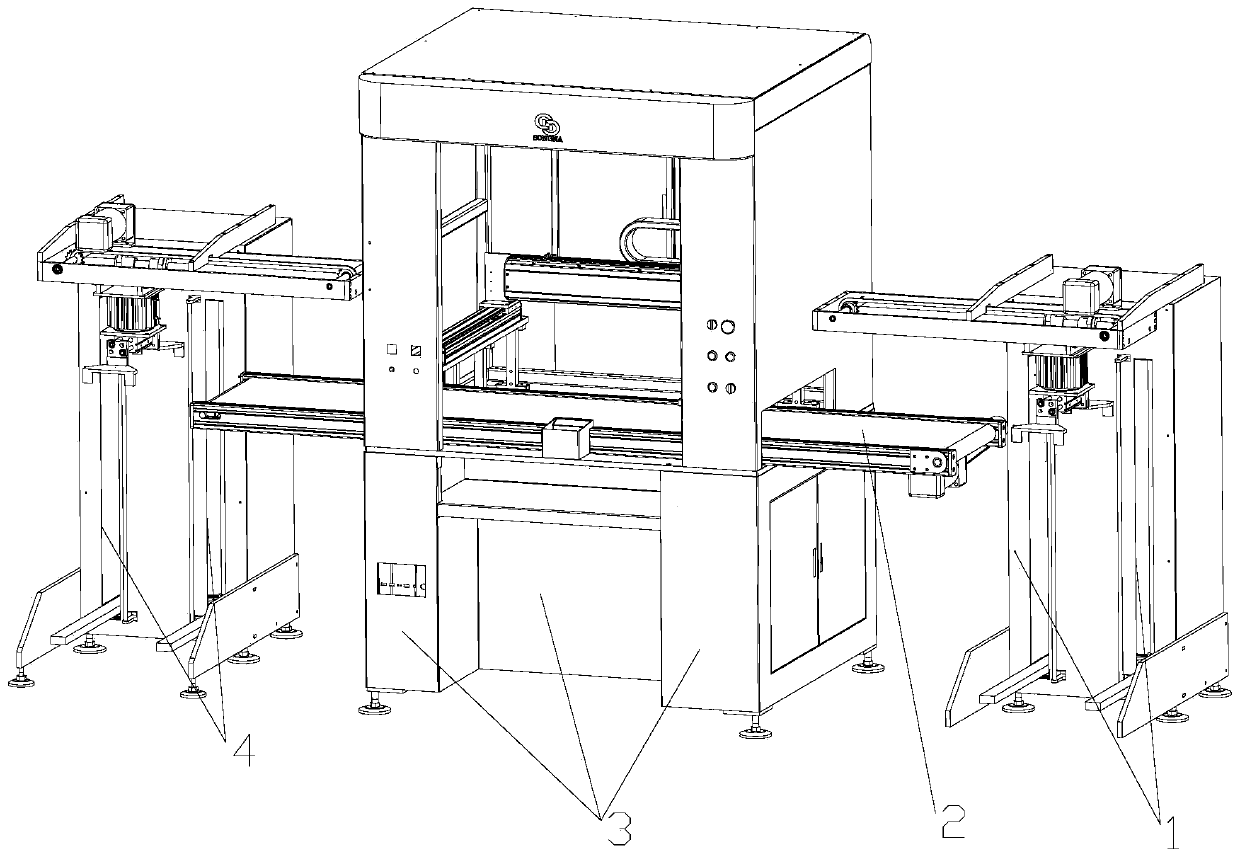

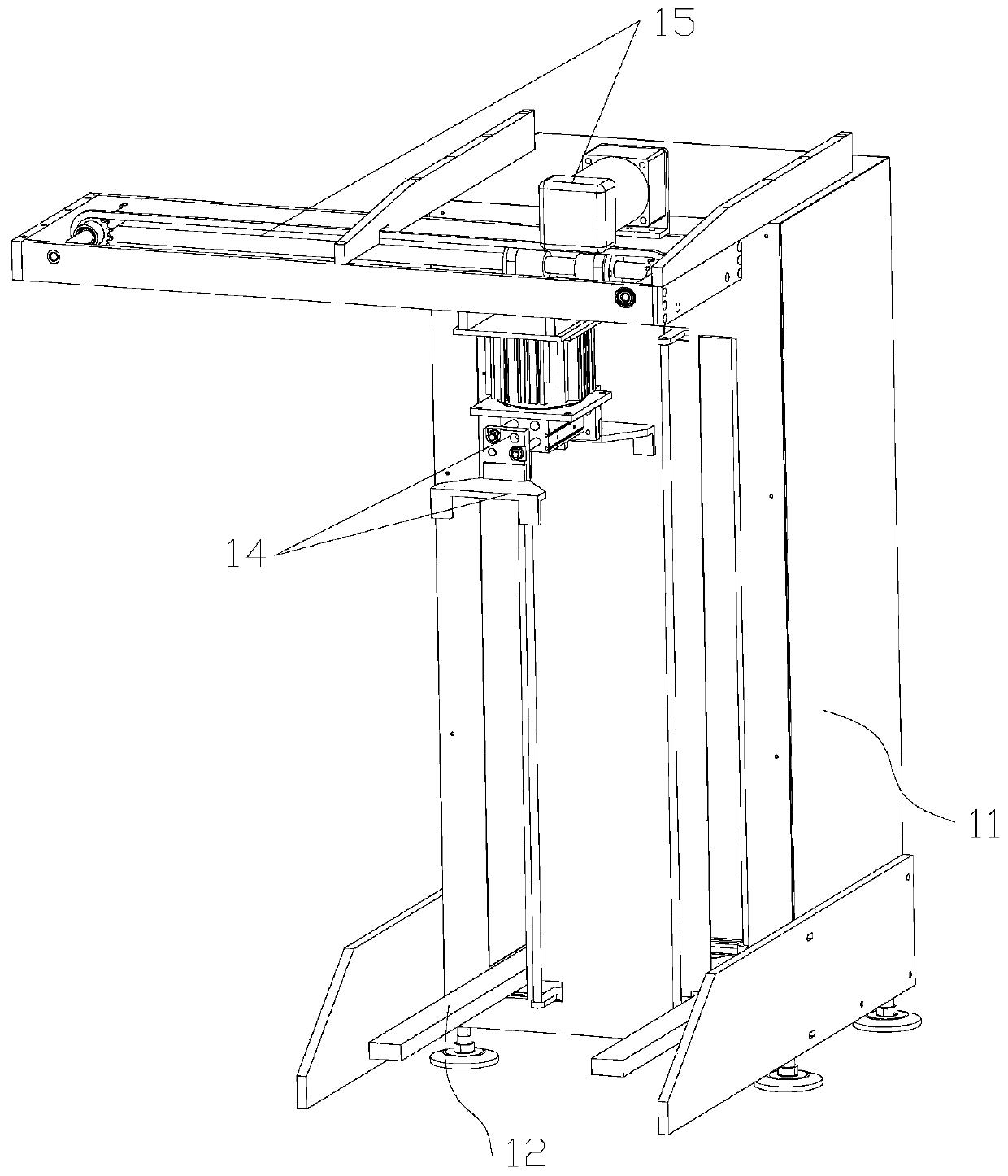

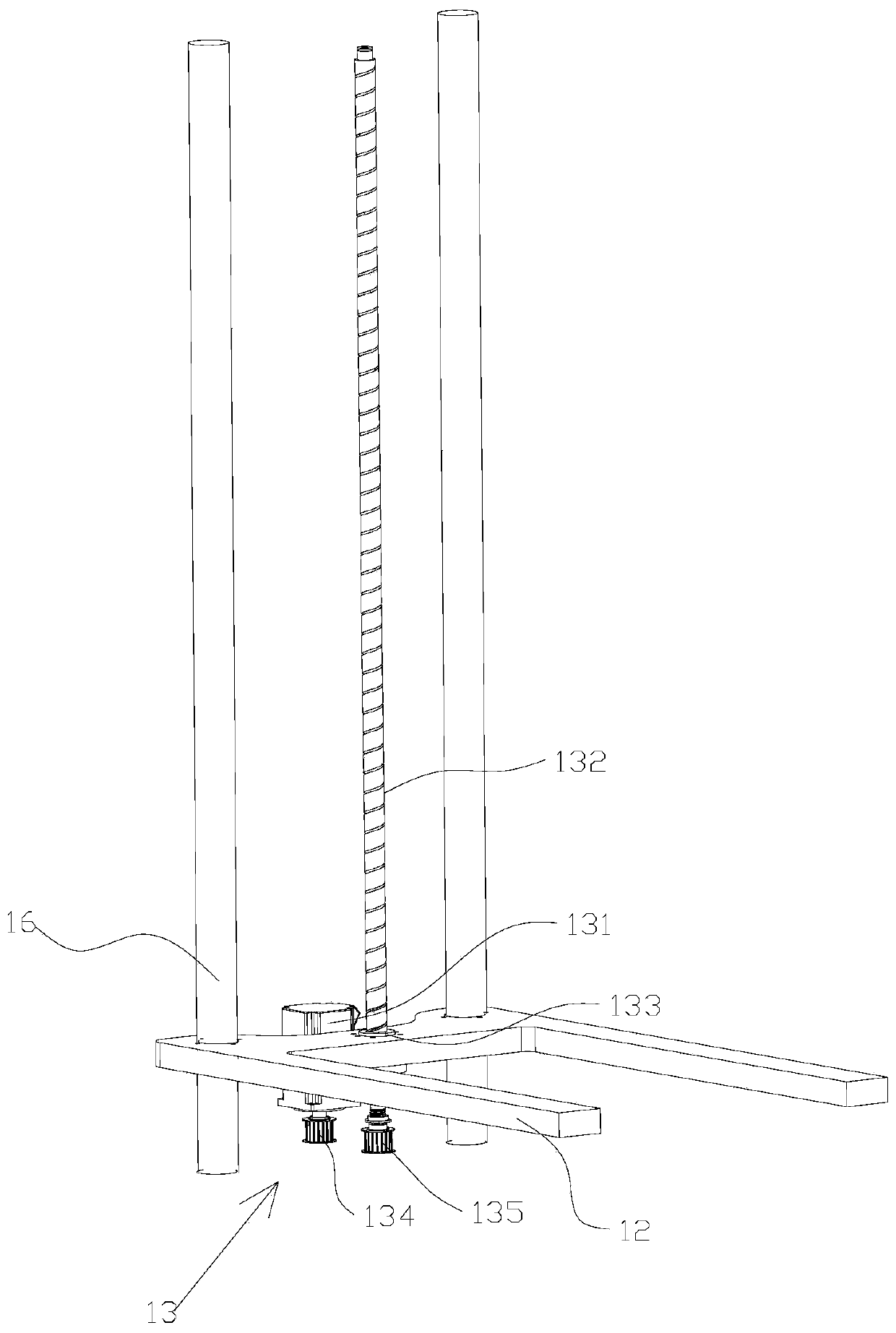

[0022] Figure 1 to Figure 6 It schematically shows the structure of an automatic point drilling machine with a loading and unloading device according to an embodiment of the present invention.

[0023] Figure 1 to Figure 6 As shown, an automatic point drilling machine with a loading and unloading device includes a feeding device 1 , a transmission device 2 , a dispensing and drilling device 3 and a feeding device 4 .

[0024] The functions of each device are described below: the workpiece can be placed on the feeding device 1, and the feeding device 1 can place the workpiece on the transmission device 2, and the transmission device 2 can drive the workpiece to move, and finally reach the spot drilling device. Glue dispensing and drilling device 3 performs dispensing and spot drilling on the workpiece. After the dispensing and spot drilling are completed, the transmission device 2 can drive the workpiece to move to the unloading device 4, and the unloading device 4 unloads t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com