Conveying system for quickly rechecking specimen

A transmission system and specimen technology, which is applied in the field of medical testing systems, can solve the problems affecting the efficiency of emergency and review specimen procedures, the long time of specimen detection process, and affecting the patient's condition, so as to shorten the measurement cycle, shorten the transfer time, and shorten the time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

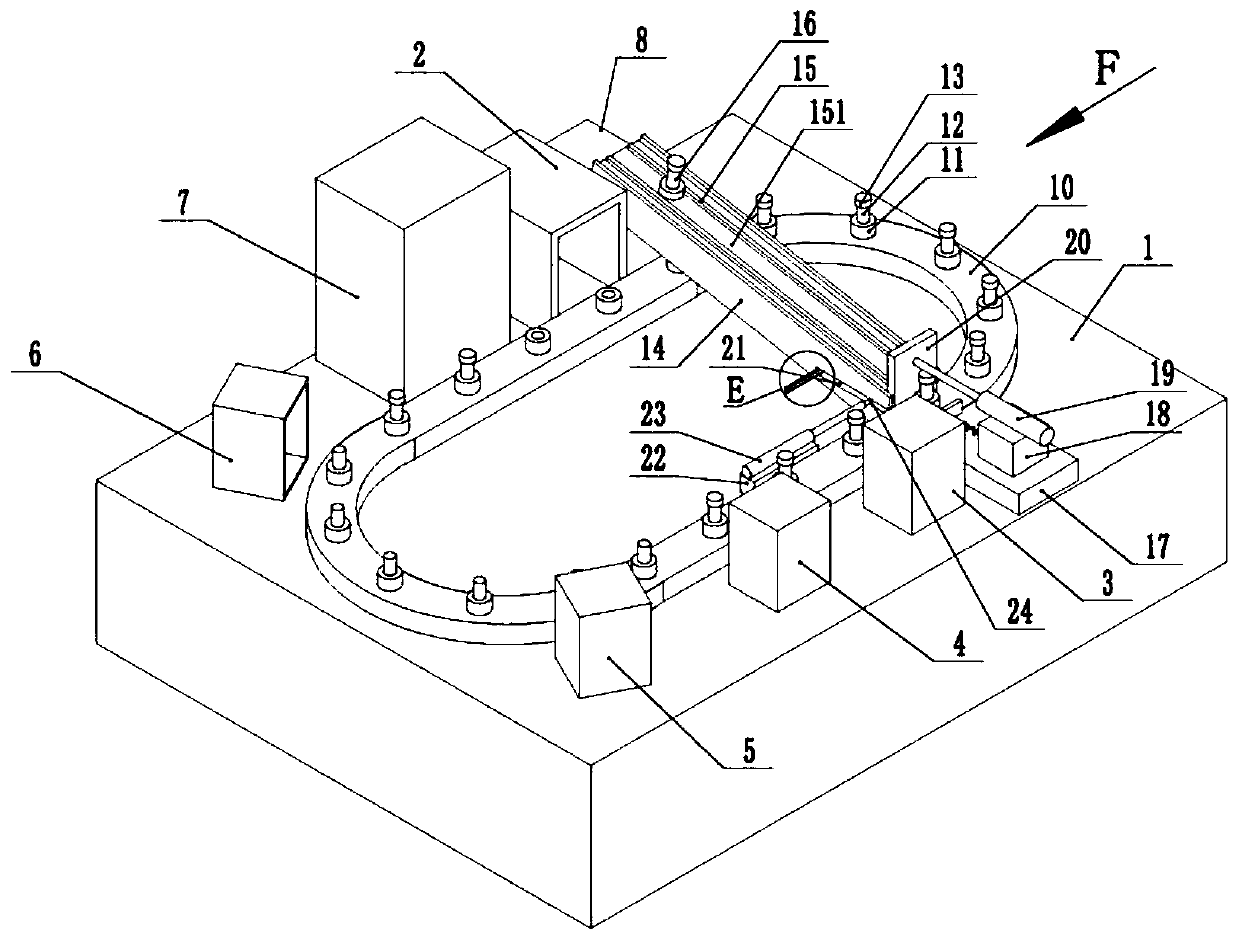

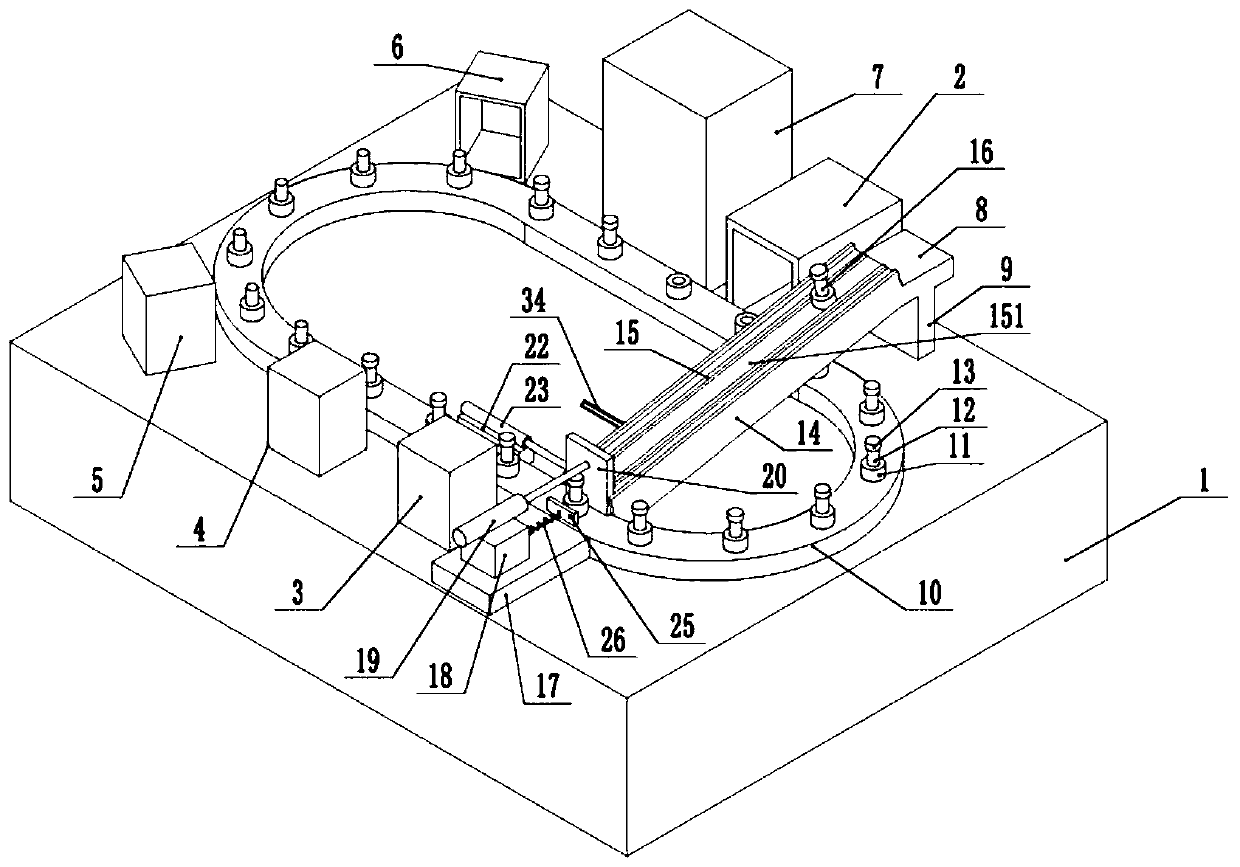

[0046] The embodiment is basically as attached figure 1 with figure 2 As shown: a transmission system for rapid re-examination of specimens, including a workbench 1, on which a conveyor belt 10 is installed. The transmission path of the conveyor belt 10 in this embodiment is circular, and the conveyor belt 10 adopts the mode of intermittent transmission , the transmission time of the conveyor belt 10 can be set by manual adjustment.

[0047] The transmission system in this embodiment is a system used to transmit the specimens to be tested by patients. The specimens are divided into common specimens and re-examination specimens 16. Common specimens refer to: after normal queuing, according to the normal inspection order The specimens put on the conveyor belt 10 for transmission, and the re-examination specimens 16 refer to: specimens that do not meet the requirements or specimens that need to be re-tested, as well as specimens of emergency patients. The specimen is loaded wi...

Embodiment 2

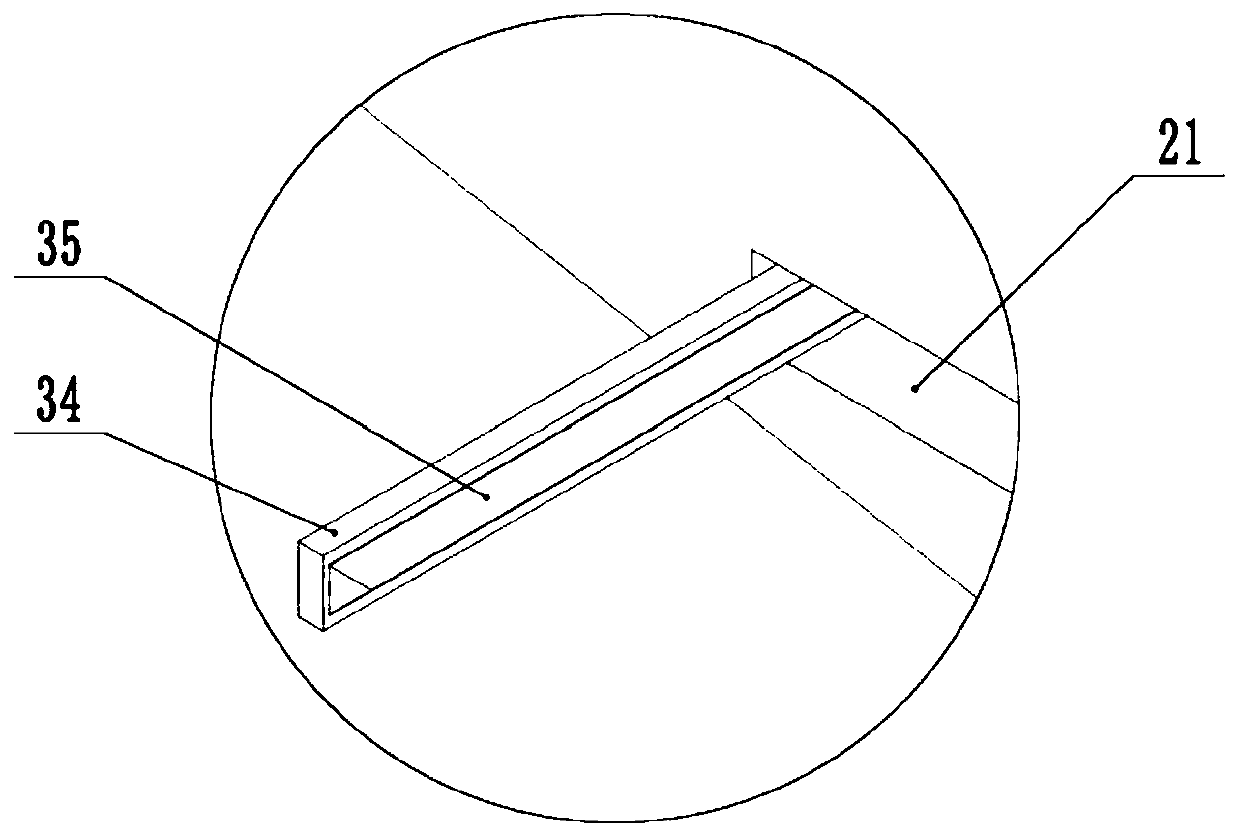

[0066] Such as Figure 9 with Figure 10 As shown, a transmission system for rapid re-examination of specimens differs from Embodiment 1 in that: the upper end of the mounting plate 17 is welded and fixed with two parallel guide plates 28, and the two guide plates 28 are aligned with the re-examination track 14. The pair is set, and the distance between the two guide plates 28 is greater than the width of the push plate 20, so that the push plate 20 can slide between the two guide plates 28.

[0067] The upper end of the mounting plate 17 is also welded and fixed with two second guide rods 27 parallel to each other. The two second guide rods 27 are all located between the two guide plates 28. The distance between the two second guide rods 27 is greater than that of the tray 11. diameter, so that the sample vial 12 containing common samples can slide between the two second guide rods 27 .

[0068] The bottom of push plate 20 and baffle plate 25 are all provided with two throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com