Closed flowerpot blank automatic manufacturing method

A production method and blank body technology, which is applied in the field of automatic forming of bottle-shaped flowerpot blanks, can solve the problems of less functions, insufficient efficiency, and excessive manual participation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0067] see Figure 18 , as an embodiment of the present invention, the automatic production method of the closed flowerpot body includes the following steps: preparation of the automatic ceramic drawing machine → batching → raw material homogenization → body parameter setting → drawing forming → blank trimming → drying → Firing → inspection; it is characterized in that each step is as follows:

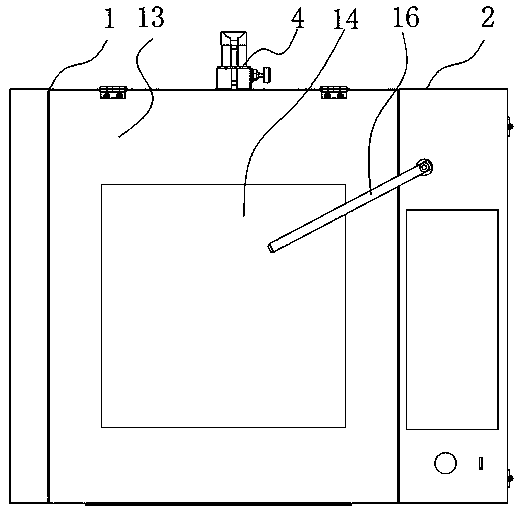

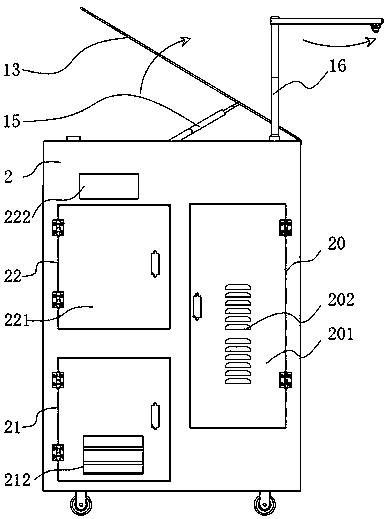

[0068] Step S1: Preparation of automatic ceramic drawing machine, see figure 1 ~ Figure 8 , the automatic ceramic drawing machine includes a closed space 1 for installing the forming mechanism, the closed space 1 is provided with a frame 11 inside, and the frame 11 is provided with an automatic drawing machine for making a bottle-shaped flower pot blank 01 Mechanism 5, the closed space 1 is provided with an openable airtight door 12 on the front, and a temperature sensor 29 is provided in the closed space 1; an additional cabinet 2 is provided outside the closed space 1, and an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com